Corrosion-resistant nickel-base alloy overlay welding powder

A nickel-based alloy, alloy powder technology, applied in welding medium, welding equipment, metal processing equipment and other directions, can solve problems such as poor effect, and achieve the effect of improving service life and good workmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

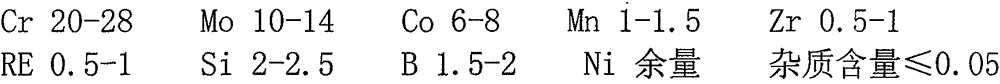

[0016] A corrosion-resistant nickel-based alloy surfacing powder, calculated in % by weight, is composed of the following components:

[0017] Cr 20 Mo 10 Co 6 Zr 0.5 RE 0.5 Mn 1 Si 2

[0018] B 1.5 Ni balance Impurity content 0.05

Embodiment 2

[0020] A corrosion-resistant nickel-based alloy surfacing powder, calculated in % by weight, is composed of the following components:

[0021] Cr 24 Mo 12 Co 7 Zr 0.8 RE 0.8 Mn 1.2 Si 2.3

[0022] B 1.8 Ni balance Impurity content 0.05

Embodiment 3

[0024] A corrosion-resistant nickel-based alloy surfacing powder, calculated in % by weight, is composed of the following components:

[0025] Cr 28 Mo 14 Co 8 Zr l RE 1 Mn 1.5 Si 2.5

[0026] B 2 Ni balance Impurity content 0.05

[0027] In Examples 1, 2 and 3, Ni:Co is 5:1-10:1; Cr:Mo is 2:1; in the process of making alloy powder, Mn, Zr and RE are added one by one in this order.

[0028] The corrosion-resistant nickel-based alloy surfacing powder of the invention is prepared by smelting in an induction heating furnace and a high-purity nitrogen atomization method. The powder morphology is silver-gray, and the spherical particle powder has good fluidity (14s / 50g) and high bulk density (4.6g / cm2). 3 ), the oxygen content is ≤500PPM, and the preferable particle size range is 212-20μm.

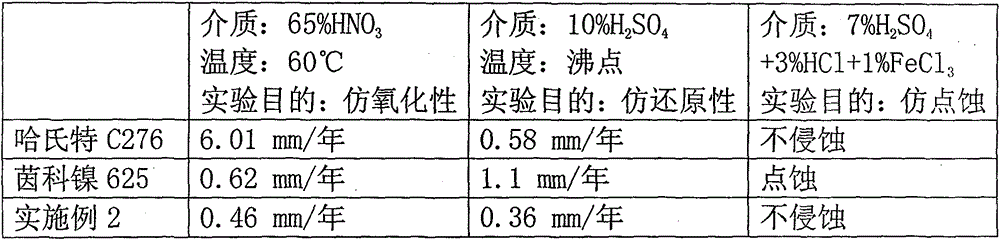

[0029] The comparison test results of Example 2 of the corrosion-resistant nickel-based alloy surfacing powder of the present invention and Hastelloy C276 and Inconel 625 alloys in the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com