Preparation method and application of six-component high-entropy alloy powder and laser cladding layer

一种高熵合金、合金粉末的技术,应用在多主元激光熔覆用高熵合金粉末及熔覆层制备领域,能够解决激光熔覆高熵合金涂层少等问题,达到提高自熔性、耐磨性好、硬度高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0029] 1. Calculate the ratio of FeNiCrAlSiCu high-entropy alloy powder according to the molar ratio: Fe is 16.67mol%, Ni is 16.67mol%, Cr is 16.67mol%, Al is 16.67mol%, Si is 16.66mol%, Cu is 16.66mol% , the total molar ratio is 100%, and electronic scales are used to weigh the powders of various elements.

[0030] 2. Pour into a mortar and grind in the mortar for half an hour to mix well.

[0031] 3. Mix the prepared laser cladding powder, 92% and 8% ethanol to form a paste or paste, and then coat it on the surface of 42CrMo steel with a preset layer thickness of 1 mm. After air-drying, laser cladding is performed.

[0032] 4. Laser cladding process parameters are: laser power 1550KW, spot diameter 0.8mm, scanning speed 180mm / min, defocusing distance 0mm, protective gas argon, gas flow rate 25L / min.

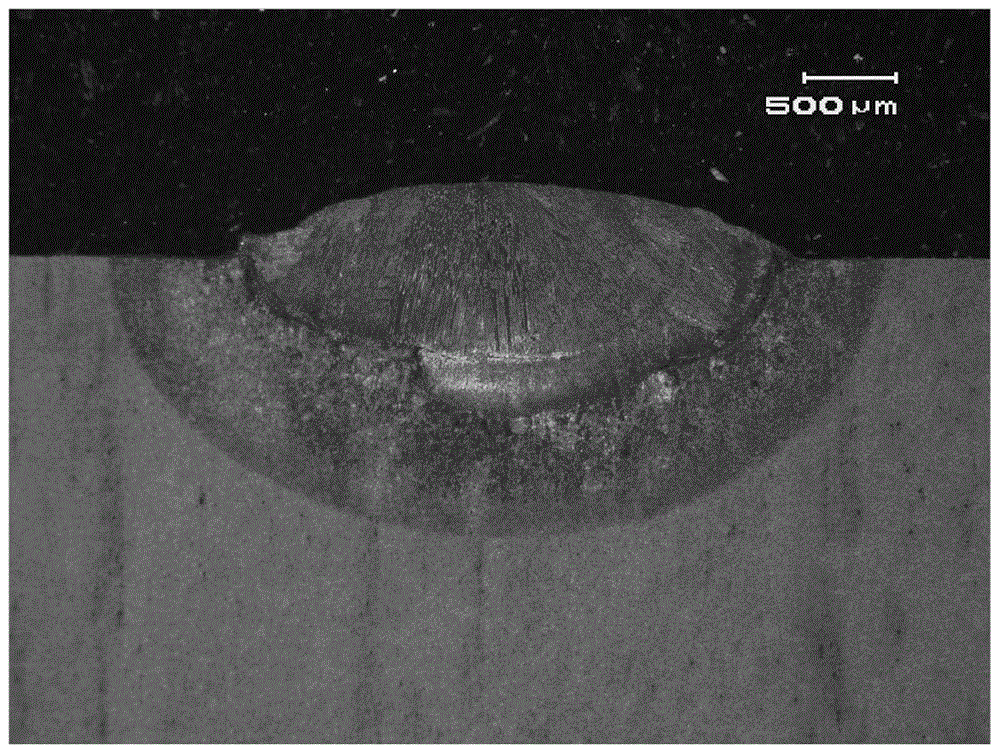

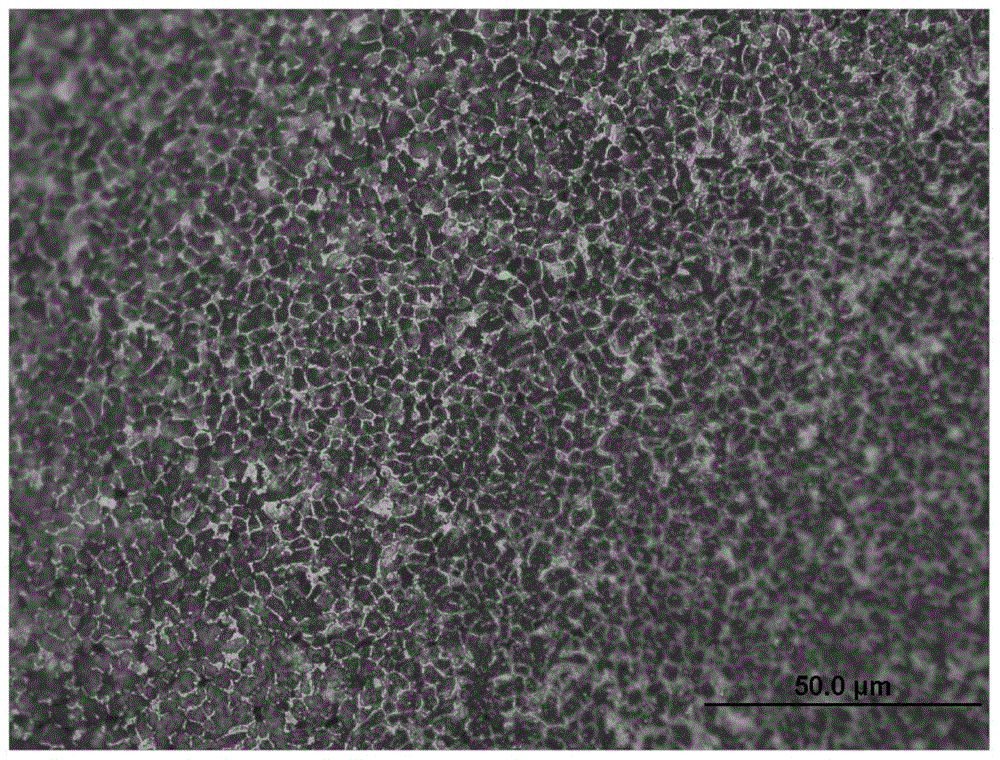

[0033] 5. After laser cladding, aqua regia was used to corrode, and the metallographic photos of the cladding layer were obtained.

[0034] The microhardness of the cladding ...

Embodiment example 2

[0039] 1. Mix the prepared laser cladding powder, 95% and 5% ethanol into a paste or paste, and then coat it on the surface of 42CrMo steel with a preset layer thickness of 2 mm. After air drying, perform laser cladding.

[0040] 2. Laser cladding process parameters are: laser power 1650KW, spot diameter 1.0mm, scanning speed 200mm / min, defocusing distance 0mm, protective gas helium, gas flow rate 20L / min.

[0041] 3. Use the same performance test, the results are shown in the table below:

[0042]

Embodiment example 3

[0044] 1. Mix the prepared laser cladding powder, 94% and 6% ethanol into a paste or paste, and then coat it on the surface of 42CrMo steel with a preset layer thickness of 1.5mm. After air-drying, laser cladding is performed.

[0045] 2. Laser cladding process parameters are: laser power 1620KW, spot diameter 0.9mm, scanning speed 180mm / min, defocusing distance 0mm, protective gas argon, gas flow rate 22L / min.

[0046] 3. Use the same performance test, the results are shown in the table below:

[0047]

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com