Preparation method for bottom mud brick

A technology of bottom mud and river bottom mud, which is applied in environmental engineering and fields, can solve problems such as pollution and non-compliance with the requirements of sustainable development strategies, and achieve the effects of low energy consumption, high strength, and low dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Preparation of Bottom Mud Bricks

[0031] The preparation method of bottom mud brick in the present embodiment may further comprise the steps:

[0032] Firstly, the river bottom mud is used as raw material, after dehydration, drying and crushing, the bottom mud, plant straw, waste glass powder, and binder are mixed in a ratio of 70:1:5:1, and then 5% steel slag is added to fully Mix evenly, add water to adjust the moisture content to 20%, stir evenly, beat for homogenization, pressurize and press with a brick mold. The suitable mixing ratio in the present invention is: bottom mud: plant straw: waste glass powder: binder is 70-90: 0.1-3: 5-15: 0.1-10, and steel slag is added, and steel slag accounts for the total of the aforementioned mixing components. 5% of the weight. Moisture content can be adjusted in the range of 20-40%.

[0033]The river sediment used is the surface sediment and shallow sediment above the hard mud at the bottom of the polluted river c...

Embodiment 2

[0038] Example 2 Determination of heavy metal leaching of bottom mud bricks

[0039] The bottom mud bricks of the present invention prepared according to the method of Example 1 are used as building materials to pave roads, and will not dissolve harmful substances such as heavy metals after soaking in rainwater, will not cause water pollution, and will not endanger human health. The experimental results are shown in Table 1, showing that the heavy metal leaching rate of the bottom mud brick of the present invention is within the specified limit.

[0040]

[0041] In this example, two different leaching solutions were used for leaching by flipping and vibrating, namely, a solution of pH=3.2 prepared by sulfuric acid and nitric acid at a volume ratio of 3:2 and an acetic acid buffer solution of pH=4.93 (refer to the standard HJT299-2007 and standard HJT300-2007). It can be seen from Table 1 that the leaching concentration of heavy metals in the bottom mud bricks of the prese...

Embodiment 3

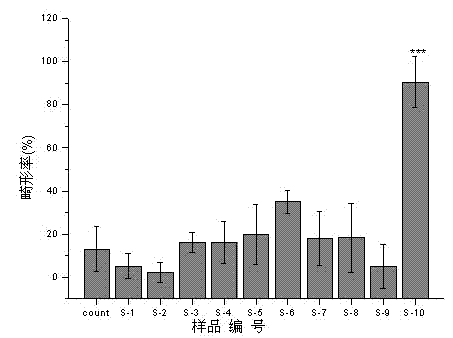

[0042] Example 3 Toxicity Analysis of Bottom Mud Brick Leachate

[0043] Use fully aerated distilled water to extract by shaking at a solid-to-liquid ratio of 1:4, expose the Xenopus laevis embryos to the extract of bottom mud bricks and raw bottom mud of the present invention for 48 hours, and observe their development status, (such as figure 1 Shown sample numbers S-1 to S-9 are brick samples worth within the proportioning range given by the present invention, and sample number S-10 is the raw material bottom mud), and the experimental results show that it is exposed to the raw material bottom mud extract The deformity rate of embryos is obviously higher than that exposed to the brick samples of the present invention, and the deformity rate of embryos exposed to the extract of the raw material bottom mud is as high as 90%, while the deformity rate of embryos exposed to the bricks of the bottom mud of the present invention is lower than 20%. It can be seen that the biotoxicit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com