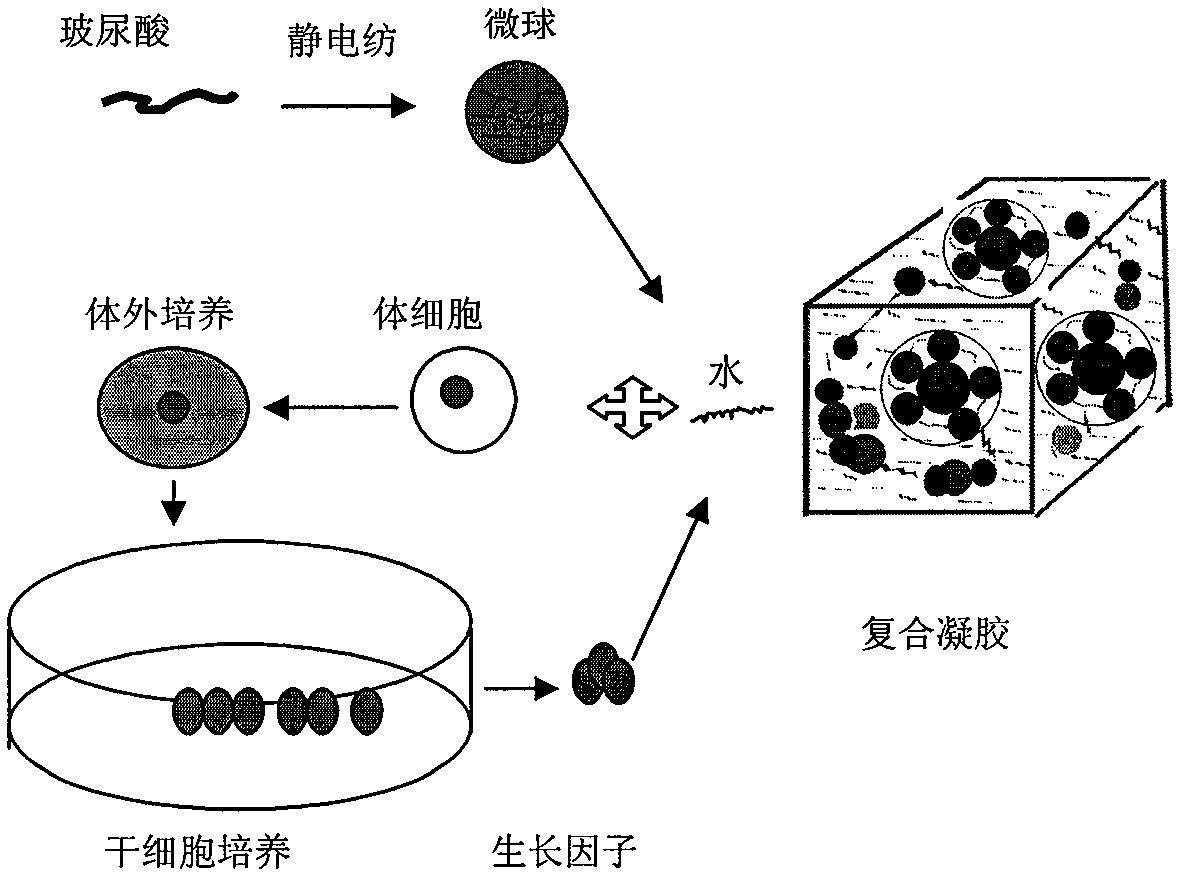

Injection gel containing submicron hyaluronic acid microspheres and preparation method thereof

A hyaluronic acid and sub-micron-level technology, which is applied in the fields of repairing defective tissues or constructing organs, manufacturing medical materials, and tissue engineering technology preparation, can solve problems such as poor plasticity, achieve no inflammation, good biocompatibility, The effect of low heavy metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

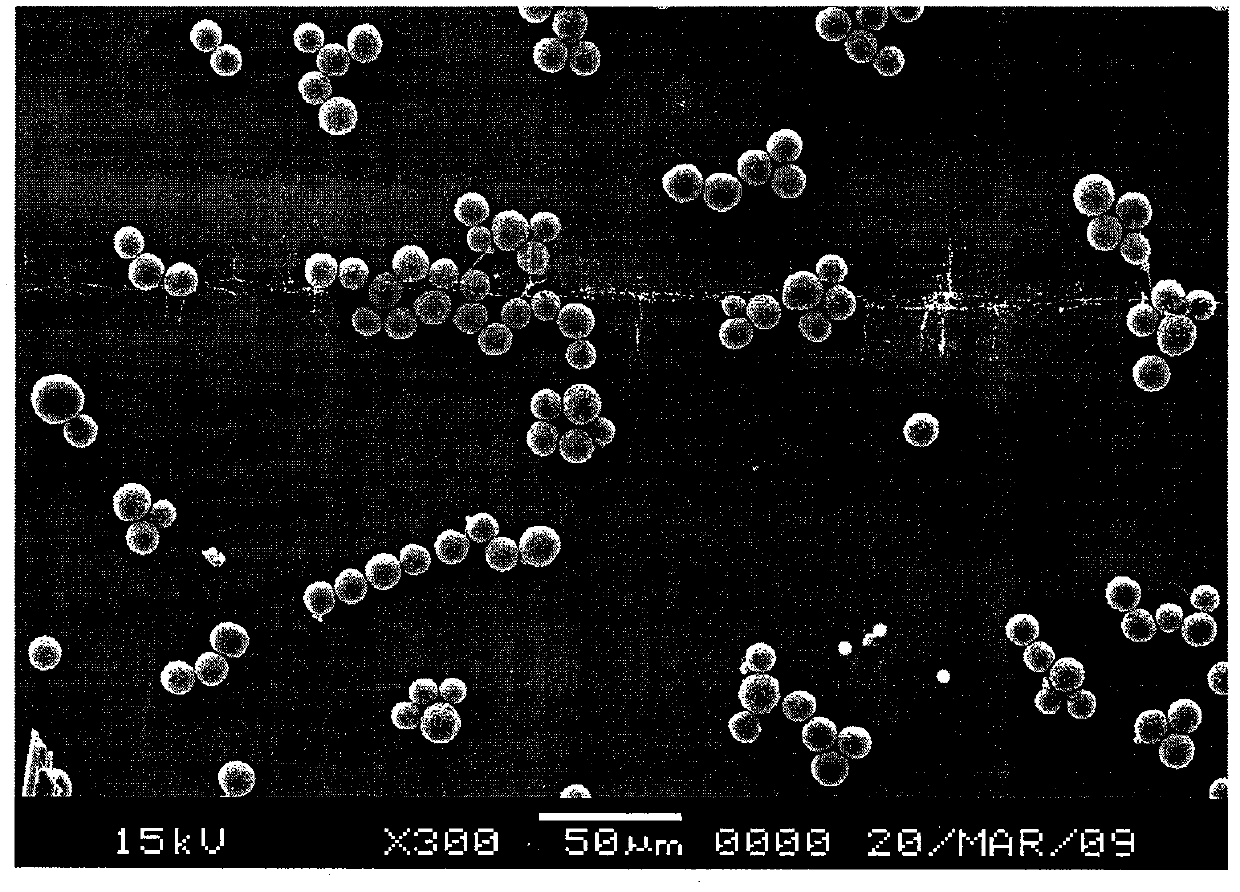

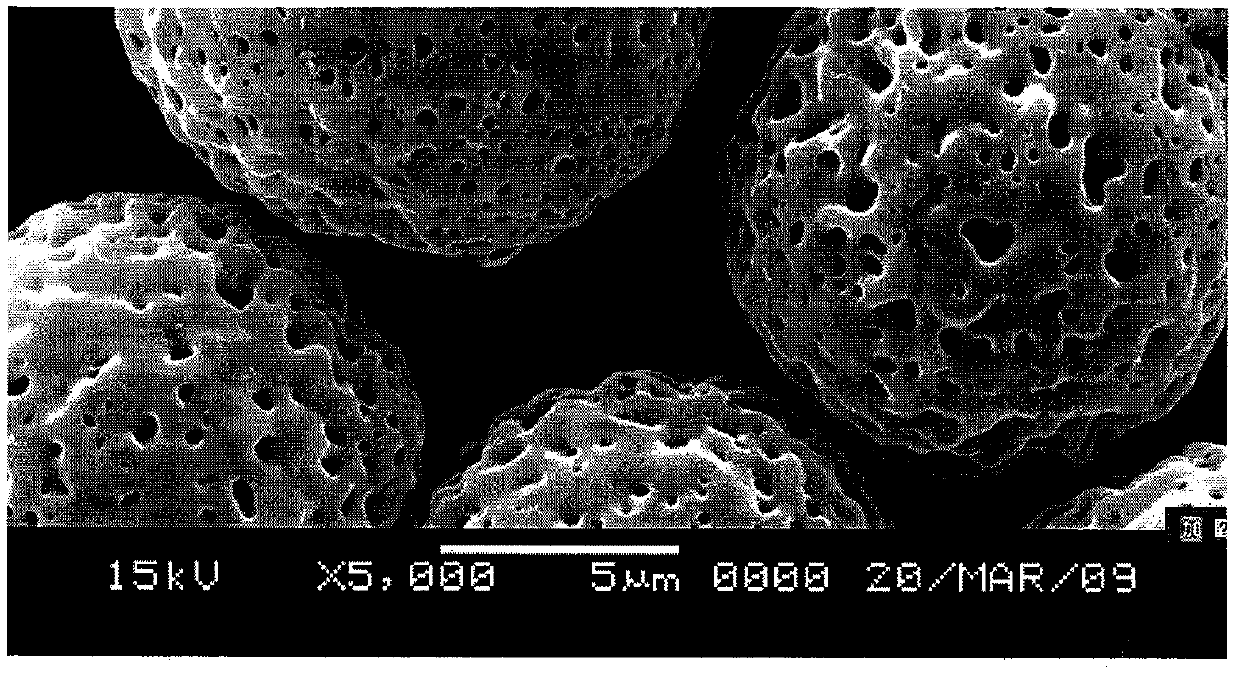

[0033] (1) Preparation of nano / submicron microspheres

[0034] The purified hyaluronic acid with a weight fraction of 0.2% was dissolved in the organic solvent trifluoroethanol to obtain a transparent and uniform electrospinning dope.

[0035] Electrospinning was performed with the prepared electrospinning dope. The spinning parameters were controlled at a voltage of 15kv, a nozzle aperture of 0.4mm, a solution flow rate of 1ml / h, an ambient temperature of 20°C, and a spacing of 15cm between the receiving plate and the nozzle.

[0036] In a 500ml container with a dielectric function, add the prepared alkaline solution with pH>10 and a concentration of 0.05M, and add 1g / 500ml of adipic acid dihydrazide (ADH) at the same time, and the reaction temperature in the container is 5 ℃ , hyaluronic acid gel microspheres with cross-linking function were obtained after electrospinning.

[0037](2) soaking, washing, and extracting the nano-microspheres prepared in the step 1 with absolu...

Embodiment 2

[0041] (1) Preparation of nano / submicron microspheres

[0042] The purified hyaluronic acid was dissolved in trifluoroethanol and water with a volume ratio of 80 / 20 to prepare a weight fraction of 1% to obtain a transparent and uniform electrospinning dope.

[0043] Electrospinning was performed with the prepared electrospinning dope. The spinning parameters were controlled at a voltage of 5kv, a nozzle aperture of 0.2mm, a solution flow rate of 0.5ml / h, an ambient temperature of 20°C, and a spacing of 5cm between the receiving plate and the nozzle.

[0044] In a 500ml container with a dielectric function, add the prepared alkaline solution with pH>10 and a concentration of 4M, and at the same time add 25g / 500ml adipic acid dihydrazide (ADH), the reaction temperature in the container is 100 ℃, Hyaluronic acid gel microspheres with cross-linking function were obtained by electrospinning.

[0045] (2) soaking, washing, and extracting the submicron microspheres prepared in the ...

Embodiment 3

[0049] (1) Preparation of nano / submicron microspheres

[0050] The purified hyaluronic acid was dissolved in hexafluoroisopropanol and water solvent (volume ratio 50 / 50) to prepare a weight fraction of 5% to obtain a transparent and uniform electrospinning dope.

[0051] Electrospinning was performed with the prepared electrospinning dope. The spinning parameters were controlled at a voltage of 10kv, a nozzle aperture of 1mm, a solution flow rate of 0.2ml / h, an ambient temperature of 20°C, and a spacing of 5cm between the receiving plate and the nozzle.

[0052] In a container with a dielectric function, add the prepared alkaline solution with pH>10 and a concentration of 1M, and at the same time add 1g / ml adipic acid dihydrazide (ADH), the reaction temperature in the container is 50 ℃, the static electricity The hyaluronic acid gel microspheres with cross-linking function were obtained by spinning.

[0053] (2) soaking, washing, and extracting the nano-microspheres prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com