Preparation method of carbon electrode material with gradation pore structure for supercapacitor

A technology of supercapacitors and hierarchical pores, applied in capacitors, electrolytic capacitors, circuits, etc., can solve complex problems and achieve the effects of developed hierarchical pore structure, simple method, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 100g of powdered PVDF to 500mL of 80% KOH solution, stir to mix evenly, put it into a tube furnace protected by an argon atmosphere, heat at 2°C / min to 150°C for 2 hours, then raise the temperature to 800°C ℃ constant temperature activation 3h. Take it out after slowly cooling down to room temperature, add dilute sulfuric acid to neutralize excess KOH, and then wash with pure water to neutrality to obtain a hierarchical pore structure carbon material with a high specific surface area.

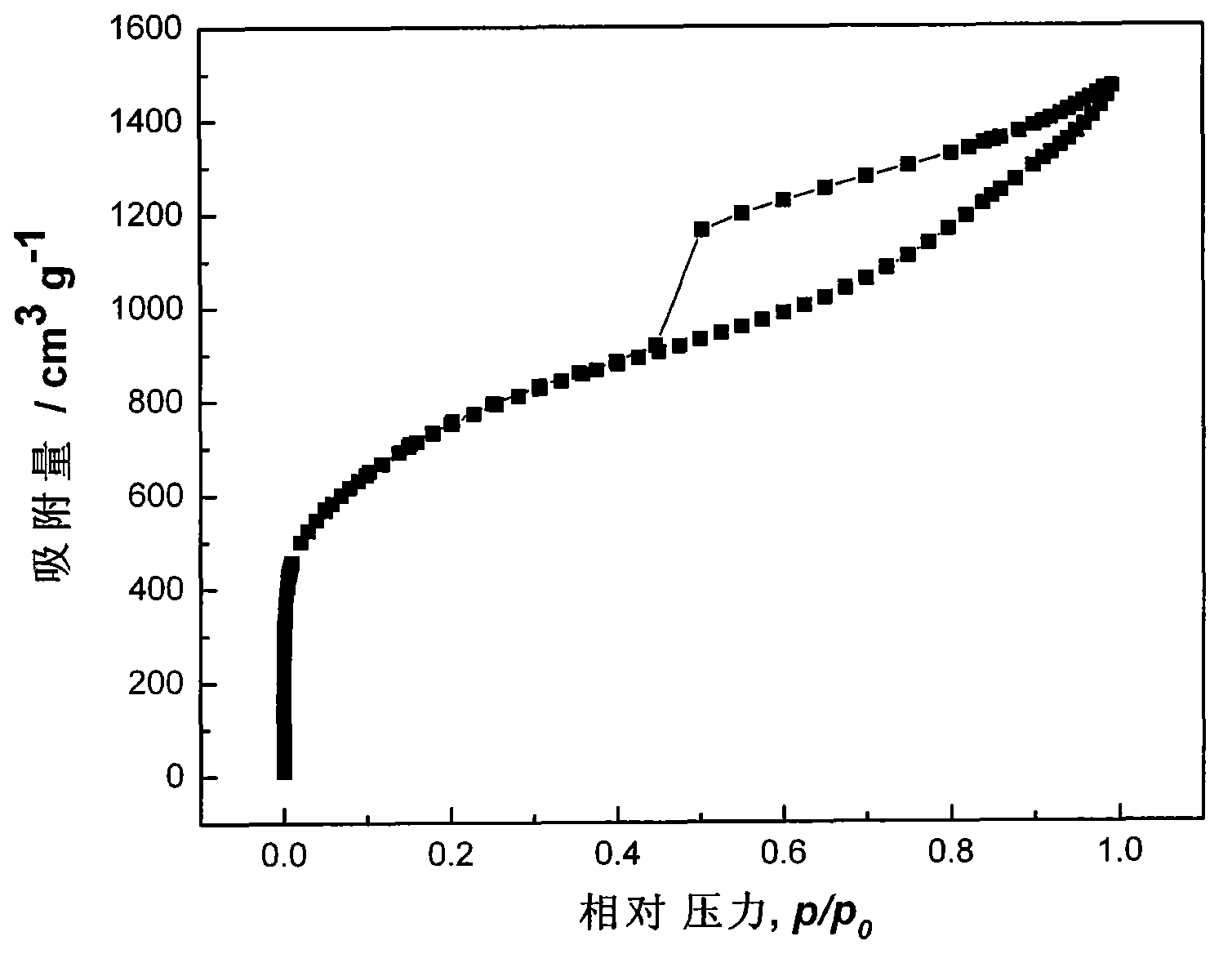

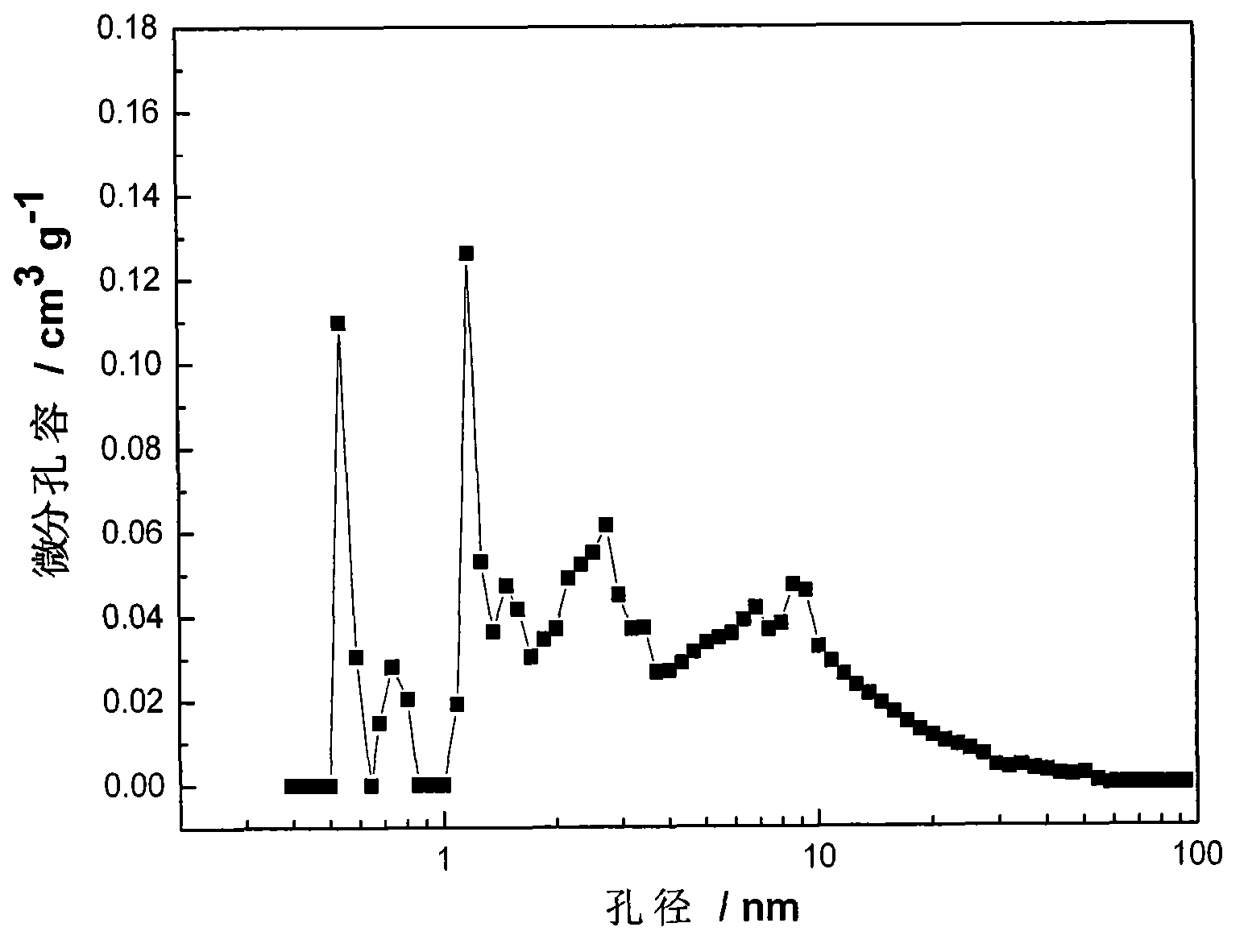

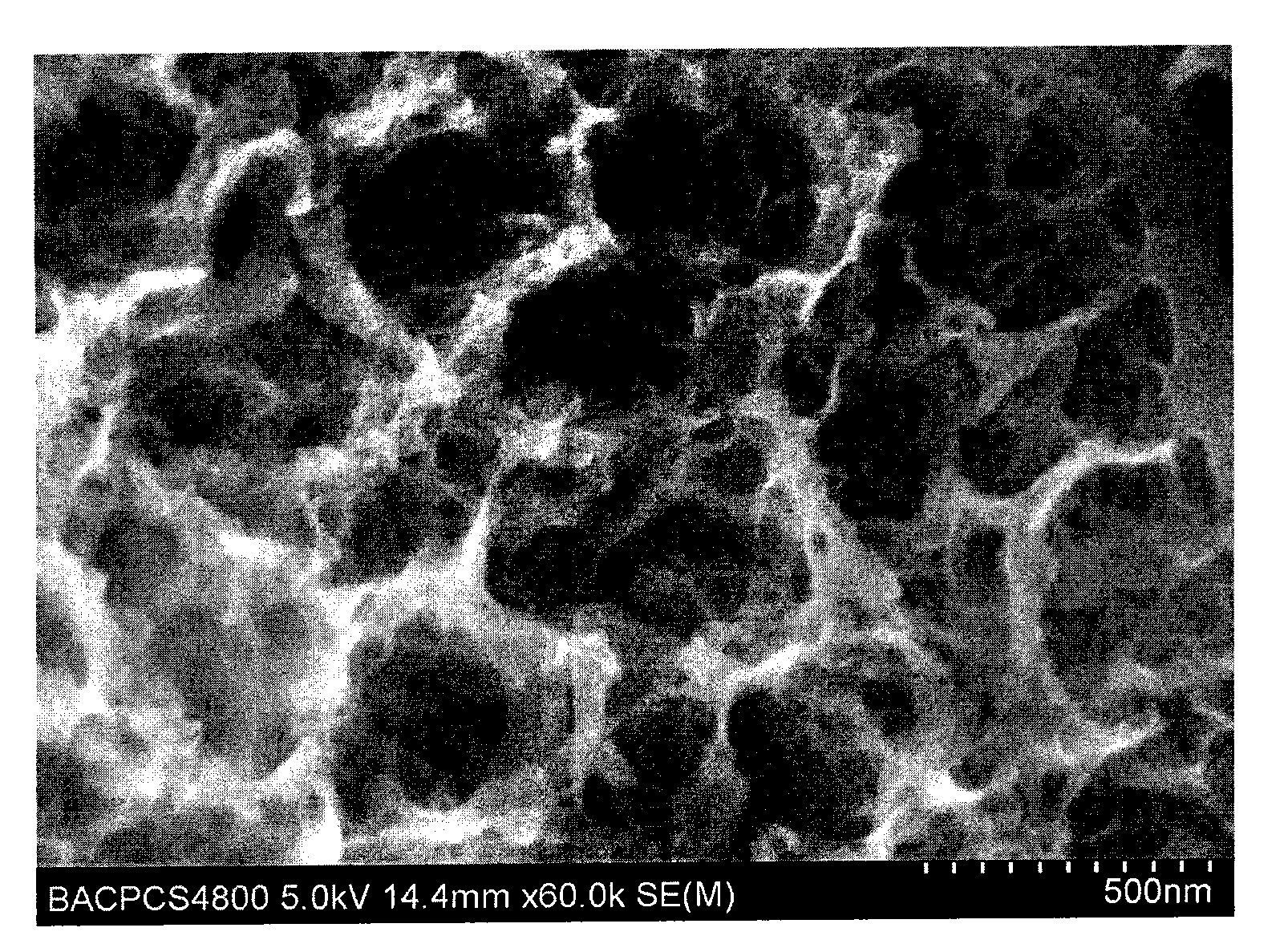

[0026] Depend on figure 1 The nitrogen absorption / desorption curve of the obtained carbon material shown in the calculation shows that its BET specific surface area is 2811m 2 / g. Depend on figure 2 The pore size distribution curve of the obtained carbon material shows that it contains abundant micropores of 0.5-2nm and mesopores of 2-50nm, and the pore volume of the micropores is 0.669cm 3 / g, the mesopore volume is 1.945cm 3 / g. The pore volume of the large pores measured by...

Embodiment 2

[0029] The PVDC was crushed to a particle size of ≤100 μm, mixed evenly with NaOH at a mass ratio of 1:3, placed in an argon-protected muffle furnace, and heated to 700°C for activation at a constant temperature for 5 hours. After slowly cooling down to room temperature, take it out, add ethylene hydrochloric acid to neutralize excess NaOH, and then wash with pure water until neutral to obtain a hierarchical pore structure carbon material with a high specific surface area.

[0030] The BET specific surface area of the obtained carbon material is 2516m 2 / g, micropore volume 0.735cm 3 / g, mesopore volume 1.335cm 3 / g, the large pore volume measured by mercury porosimetry is 3.22cm 3 / g, the specific capacity at 50mA / g current density in 6M KOH electrolyte is 355F / g, and the specific capacity at 50Ag current density maintains 205F / g; in organic electrolyte 1M Et 4 NBF 4 The specific capacitance in / PC is 160F / g, and the specific capacitance still maintains 124F / g under the...

Embodiment 3

[0032] Powder PVDF and Mg(OH) 2 and Ca(OH) 2 Mix evenly at a mass ratio of 1:3:4, place in the center of a tubular resistance furnace, pass through high-purity nitrogen protection, and heat to 900°C for 8 hours. After the furnace temperature dropped to room temperature, it was taken out, an excess of nitric acid was added, and then washed with pure water to neutrality to obtain a carbon material with a hierarchical pore structure with a high specific surface area.

[0033]The BET specific surface area of carbon materials measured by nitrogen adsorption method is 2018m 2 / g, micropore volume 0.861cm 3 / g, mesopore volume 0.882cm 3 / g, the large pore volume measured by mercury intrusion porosimetry is 2.23cm 3 / g, the specific capacity at 50mA / g current density in 6M KOH electrolyte is 315F / g, and the specific capacitance at 50A / g current density maintains 189F / g; in organic electrolyte 1M Et 4 NBF 4 The specific capacitance in / PC is 156F / g, and the specific capacitance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com