Method for preparing concave lens array structure on titanium dioxide inorganic-organic photosensitive composite film

An array structure and titanium dioxide technology, which is applied in the field of preparation of concave lens array structures, can solve problems such as errors, and achieve the effects of large hardness, adjustable refractive index and high optical transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

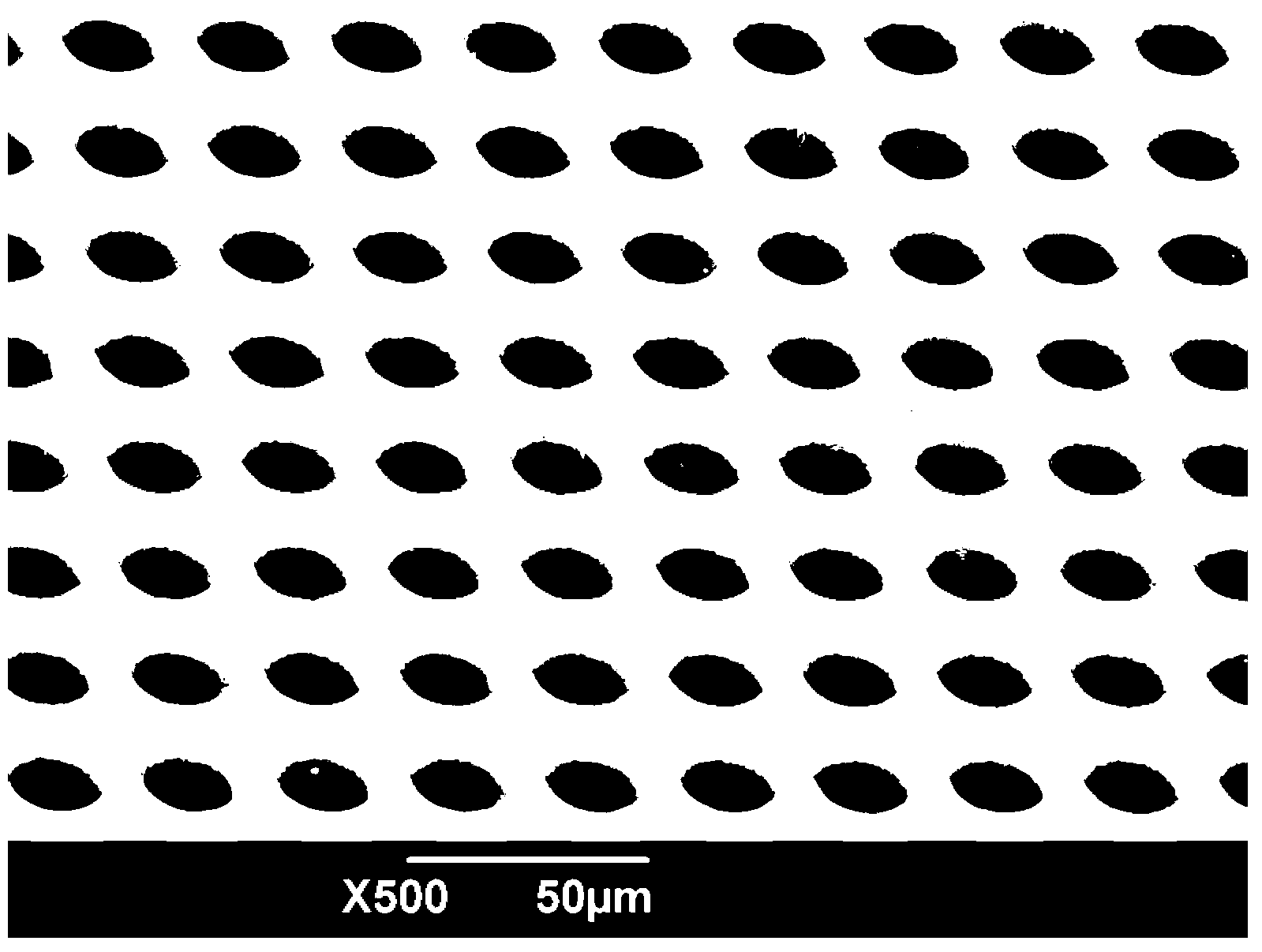

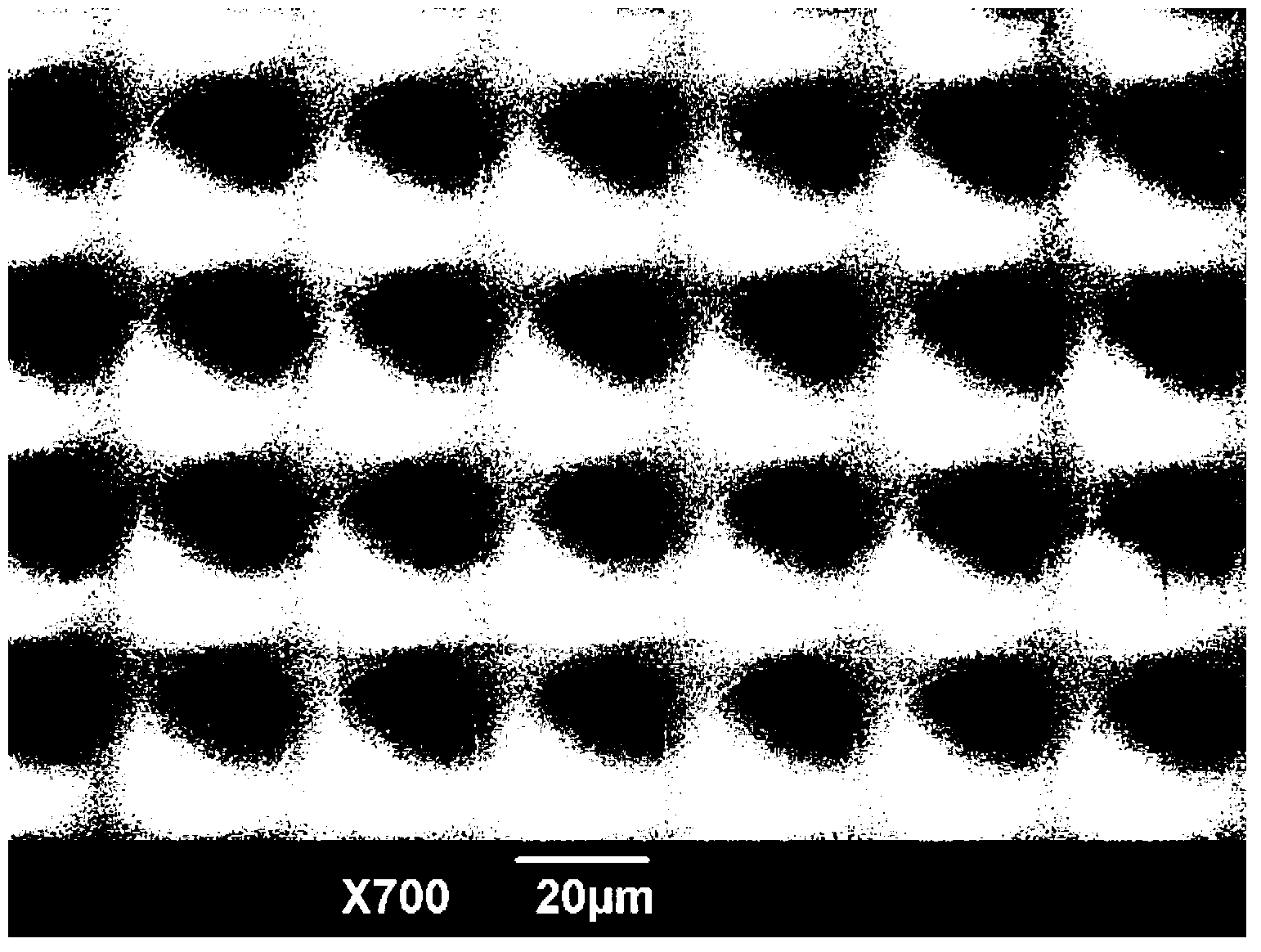

[0020] 1) First, use a JKG-2A photolithography machine to expose the AZ5214-E photoresist for 60 seconds through a circular array mask, and then develop it in an AZ-Developer developer for 60 seconds to obtain a cylindrical array structure. , and then reflow the obtained cylinder array structure on a hot plate at 160° C. for 30 minutes to obtain a photoresist master with a diameter of 20 μm and an interval of 20 μm convex lens array structure;

[0021] 2) Mix the PDMS prepolymer and curing agent of Sylgard184 at a weight ratio of 10:1 and put it in a vacuum drying oven until the air bubbles are completely removed. The photoresist master was cured in a 90°C oven for 30 minutes, and finally the fully cured PDMS was peeled off from the photoresist master with a convex lens array structure to obtain a PDMS soft template with a concave lens array structure;

[0022] 3) The mixture of PDMS prepolymer and curing agent whose air bubbles have been removed in 2) is poured onto the PDMS ...

Embodiment 2

[0025] Steps 1), 2), and 3) of this embodiment are the same as those of Embodiment 1;

[0026] 4) Using the spin-coating process, a titanium dioxide organic-inorganic composite film with UV photosensitive properties was prepared on a glass slide at a speed of 1000 rpm from the photosensitive composite base solution, and used as an embossing layer to incorporate a convex lens array structure The PDMS soft template was imprinted onto the composite film at a pressure of 2MPa for a duration of 20 minutes, and then placed directly under a UV lamp (wavelength 365nm, current 15mW / cm 2 ) was exposed and cured, and finally the fully cured photosensitive composite film was peeled off from the PDMS soft template with a convex lens array structure, and dried in an oven, thereby preparing a concave lens array structure on the titanium dioxide organic-inorganic photosensitive composite film. Among them, the depth of the concave lens array is 3.2 μm, the diameter of the concave lens is 20 μm...

Embodiment 3

[0028] Steps 1), 2), and 3) of this embodiment are the same as those of Embodiment 1;

[0029] 4) Using the spin-coating process, a titanium dioxide organic-inorganic composite film with UV photosensitive properties was prepared on a glass slide at a speed of 1000 rpm from the photosensitive composite base solution, and used as an embossing layer to incorporate a convex lens array structure The PDMS soft template was imprinted onto the composite film at a pressure of 3 MPa for 10 minutes, and then placed directly under a UV lamp (wavelength 365 nm, current 15 mW / cm 2 ) was exposed and cured, and finally the fully cured photosensitive composite film was peeled off from the PDMS soft template with a convex lens array structure, and dried in an oven, thereby preparing a concave lens array structure on the titanium dioxide organic-inorganic photosensitive composite film. The depth of the concave lens array is 3.6 μm, the diameter of the concave lens is 20 μm, and the surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com