Forward osmosis membrane bioreactor with magnetic nanoparticles serving as driving liquid

A technology of magnetic nanoparticles and bioreactors, applied in chemical instruments and methods, magnetic field/electric field water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as reducing the effect of sewage treatment, avoid inhibition, Low energy consumption and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

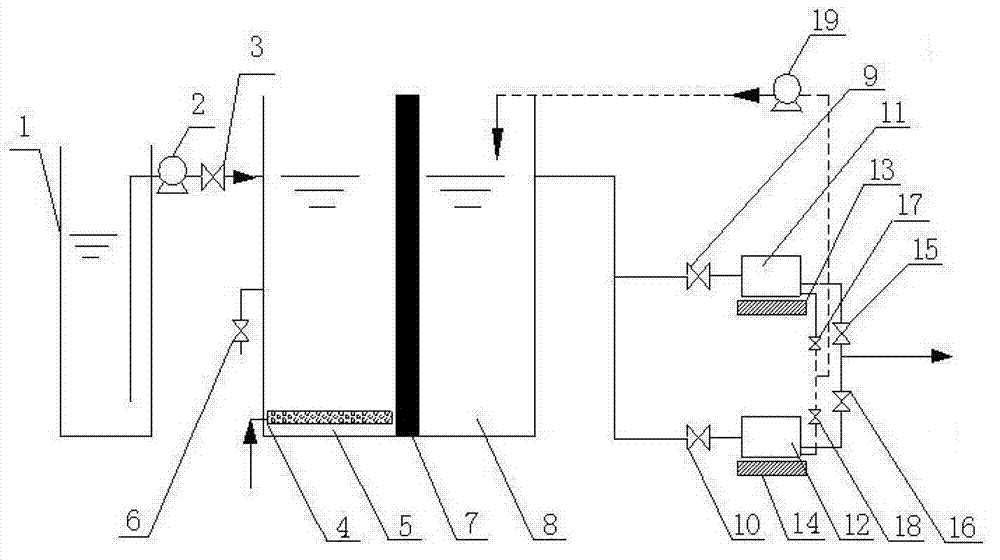

[0017] Specific implementation mode one: combine figure 1 Describe this embodiment, the forward osmosis membrane bioreactor using magnetic nanoparticles as the driving liquid in this embodiment includes a liquid storage tank 1, an inlet pump 2, a first inlet valve 3, an aeration pipe 4, a biological reaction tank 5, a drain Mud valve 6, forward osmosis membrane 7, driving liquid pool 8, second water inlet valve 9, third water inlet valve 10, first liquid storage tank 11, second liquid storage tank 12, first electromagnetic field 13, second electromagnetic field 14. The first drain valve 15, the second drain valve 16, the first backflow valve 17, the second backflow valve 18 and the pump 19, the liquid storage tank 1 communicates with the bioreactor 5 through the water inlet pump 2 and the first water inlet valve 3 , the bottom of the biological reaction tank 5 is provided with an aeration pipe 4, and the middle part of the biological reaction tank 5 is provided with a sludge d...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination figure 1 Describe this embodiment, the water quality parameter of the sewage that this embodiment enters bioreactor 5 is: chemical oxygen demand (COD) is 100~700mg / L, ammonia nitrogen concentration (NH 4 + -N) is 10~50mg / L, suspended solids concentration (SS) is 20~100mg / L, phosphate concentration (PO 4 3- P) is 1 to 10 mg / L. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Specific implementation mode three: combination figure 1 This embodiment will be described. The aeration pipe 4 in this embodiment is externally connected to an aeration system. Other compositions and connections are the same as in the first embodiment.

[0021] Specific implementation mode four: combination figure 1 To illustrate this embodiment, the forward osmosis membrane 7 in this embodiment is placed in such a way that the active layer faces the draw solution pool 8 or the active layer faces the biological reaction pool 5 . Other compositions and connections are the same as in the first embodiment.

[0022] Specific implementation mode five: combination figure 1 Illustrate present embodiment, forward osmosis membrane 7 fronts described in this embodiment are also provided with aeration pipe, the aeration rate of forward osmosis membrane 7 front aeration pipes and the aeration rate ratio of biological reaction tank 5 bottom aeration pipes are 3 ~5:1. Other com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com