Manufacturing method of patch type LED (Light-Emitting Diode) module

A technology of LED module and manufacturing method, applied in printed circuit manufacturing, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problem of multi-material cost of materials, low reliability of a single LED light source, processing technology and process time Long and other problems, to achieve the effect of low chip failure rate, saving packaging materials and packaging process time, and short process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

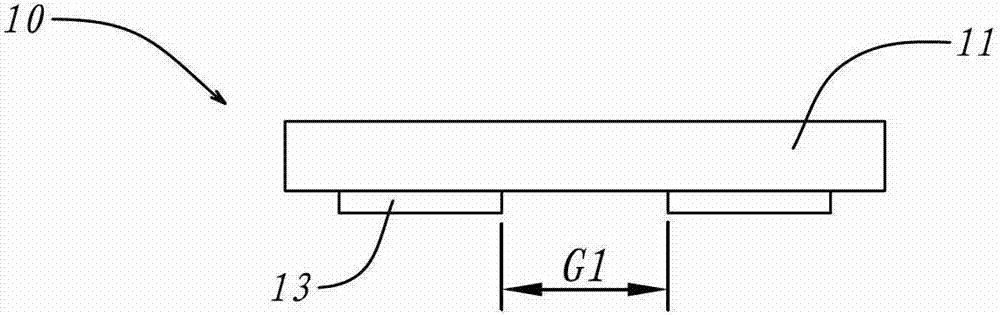

[0047] figure 1 As shown, in the LED chip 10 with a flip-chip structure used in the present invention, its main body 10 is a semiconductor material part, and the lower part is the positive and negative metal electrodes forming ohmic contact with the main body 10. The plane below the main body 10 Inside, the distance G1 between the metal electrodes 13 is 80 μm; for this type of flip-chip LED chip, the light-emitting surface 12 and the metal electrodes 13 of the conductive part are located on both sides of the main body 10 without interfering with each other, and its luminous efficiency is high.

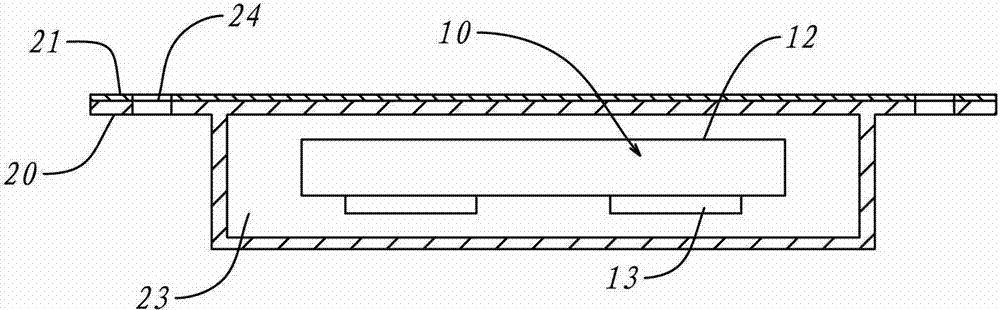

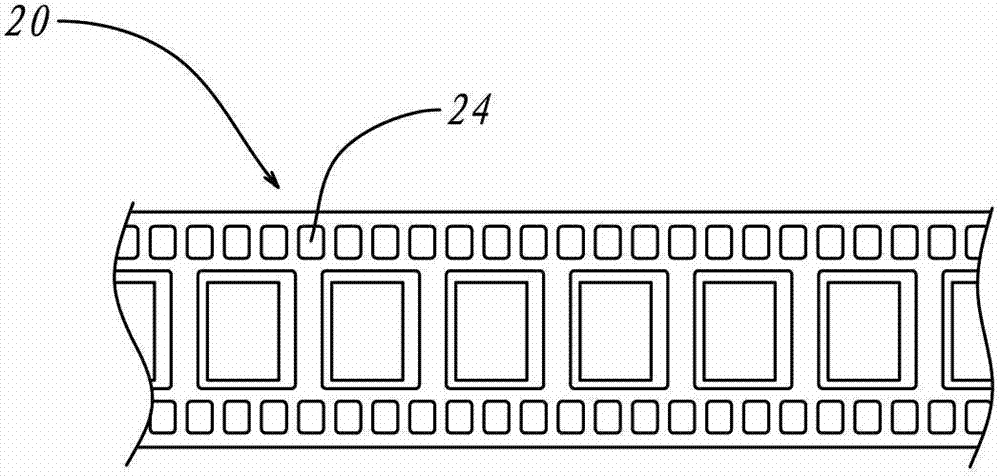

[0048] Such as figure 2 and image 3 As shown, the LED chips 10 are put into the braid 20 one by one, each LED chip occupies an accommodating space 23 and is independent of each other; and the metal electrode 13 of the LED chip 10 is located at the bottom of the accommodating space 23; The opening of the space. When the LED chips 13 are placed into the accommodating space, there wi...

Embodiment 2

[0060] Such as Figure 9 , Figure 10 , two state diagrams of Embodiment 2 of the present invention:

[0061] Compared with Embodiment 1, this embodiment is different in that in the mounting step, there is an auxiliary colloid 45 between the pads 41 of the substrate 40. The role of the auxiliary colloid 45 is that when the volume of the LED chip 10 is large, It is difficult to temporarily fix the LED chip 10 to the substrate by the tension of the solder paste 42. The auxiliary colloid 45 is used as a temporary component to make the LED chip 10 and the pad 41 relatively accurate and stable, and there will be no posture deviation even after passing through the reflow oven. .

[0062] Another difference is that after the fixing step of the LED chip 10 is completed, the light-emitting surface of the LED chip 10 is covered with the fluorescent film 50. This fluorescent film is in the form of an integral thin film and is formed separately, so it can be directly applied with approp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com