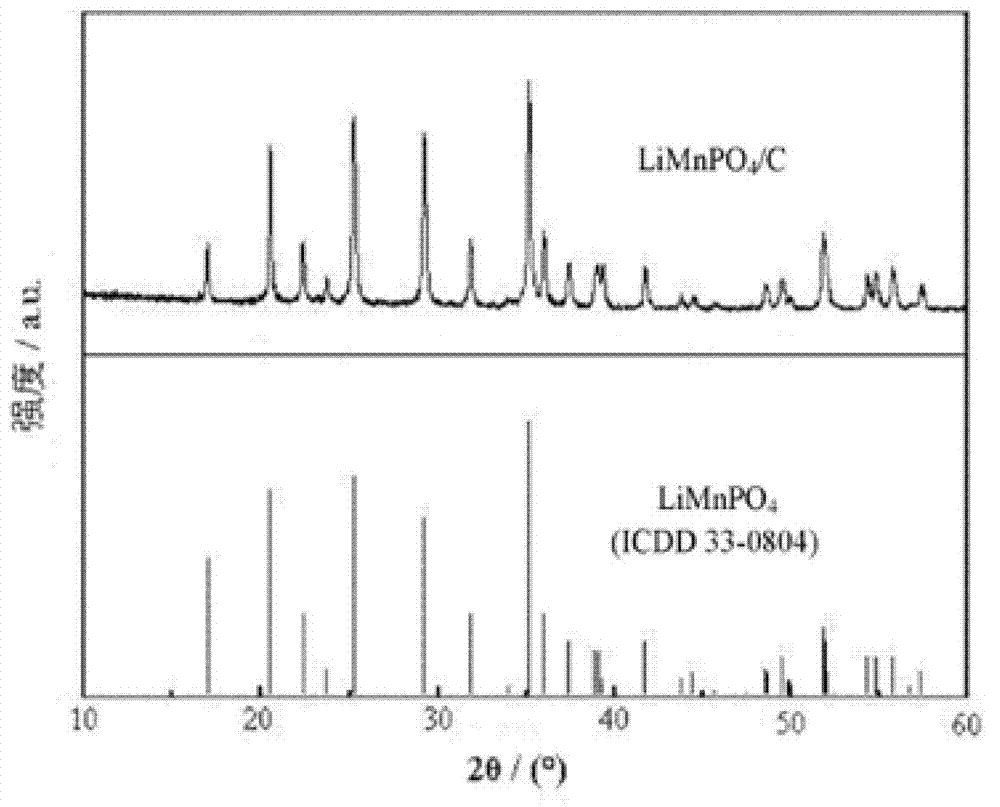

Method for synthesizing manganese phosphate lithium sol-gel doped with other metal ions

A lithium manganese phosphate sol, metal ion technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of shortening lithium ion diffusion channels, low electronic conductivity, shortening reaction time, etc., and achieves easy commercial production and operation. Simple, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of manganese phosphate lithium sol-gel synthesis method doped with other metal ions, the steps are as follows:

[0040](1) Preparation of sol: Lithium carbonate, manganese citrate, ferric citrate, phenolic resin, phosphoric acid and citric acid are dissolved in deionized water, wherein the molar ratio of lithium, manganese, iron and phosphorus in the mixture is 1.05:0.75:0.25: 1. The molar ratio of the added complexing agent to lithium source is 1:1, stir until the solution is clear.

[0041] (2) Gel preparation: Stir the clear solution obtained in step (1) vigorously at 60°C and evaporate the solvent until it becomes viscous, then dry the obtained viscous substance in a blast oven at 120°C, pulverize it, and then put it into a ball mill Ball milled for 1h to obtain the mixture powder.

[0042] (3) Calcining at high temperature: transfer the mixture powder obtained in step (2) to a porcelain boat, and calcining at 550°C for 6 hours under an inert atmosphere to o...

Embodiment 2

[0044] A kind of manganese phosphate lithium sol-gel synthesis method doped with other metal ions, the steps are:

[0045] (1) Preparation of sol: Dissolve lithium acetate, manganese acetate, magnesium acetate, glucose, phosphoric acid, and glycolic acid in deionized water, wherein the molar ratio of lithium, manganese, magnesium, and phosphorus in the mixture is 1.05:0.95:0.05:1. The molar ratio of the added complexing agent to lithium source is 1:1, and stirred until the solution is clear.

[0046] (2) Gel preparation: Stir the clear solution obtained in step (1) vigorously at 60°C and evaporate the solvent until it becomes viscous, dry the obtained viscous substance in a blast oven at 120°C, pulverize it and put it into a ball mill for ball milling 1h, the mixture powder was obtained.

[0047] (3) High-temperature calcination: transfer the mixture powder obtained in step (2) to a porcelain boat, and calcine at 600°C for 6 hours under an inert atmosphere to obtain a finishe...

Embodiment 3

[0049] A kind of manganese phosphate lithium sol-gel synthesis method doped with other metal ions, the steps are:

[0050] (1) Preparation of sol: Dissolve lithium carbonate, manganese citrate, ferric citrate, glucose, phosphoric acid and citric acid in deionized water, wherein the molar ratio of lithium, manganese, iron and phosphorus in the mixture is 1.025:0.90:0.10:1 , the molar ratio of the added complexing agent to lithium source is 1:1, stir until the solution is clear.

[0051] (2) Gel preparation: Stir the clear solution obtained in step (1) vigorously at 60°C and evaporate the solvent until it becomes viscous, dry the obtained viscous substance in a blast oven at 120°C, pulverize it and put it into a ball mill for ball milling 1h, the mixture powder was obtained.

[0052] (3) High-temperature calcination: transfer the mixture powder obtained in step (2) to a porcelain boat, and calcine at 650°C for 6 hours under an inert atmosphere to obtain the finished product of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com