Manufacture method for chlorine-evolution dimensionally stable anode (DSA) electro-catalytic electrode with three dimensional structure

A three-dimensional structure, electrocatalytic technology, applied in the direction of electrode, electrode shape/type, electrolytic coating, etc., can solve the problems of unreasonable economy, low current utilization rate, etc., achieve large application prospects, avoid impurities and uncertain factors, high The effect of electrocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of a DSA electrode for three-dimensional structure analysis of chlorine, comprising the steps of:

[0037] (1) Pretreatment of the titanium substrate: Cut the titanium substrate into a 2cm×3cm sheet sample, and polish it with 350 and 600 mesh sandpaper respectively, so that the surface of the titanium substrate presents a silver-white metallic luster, and then clean it with distilled water ultrasonically ( The ultrasonic power is 200w, the frequency is 40KHz); then the titanium substrate is dissolved and soaked in a sodium hydroxide solution with a mass concentration of 20%, heated at 95°C for 1.5 hours, and then ultrasonically cleaned with distilled water (ultrasonic power is 200w, frequency is 40KHz) ; Soak the titanium substrate with an oxalic acid solution with a mass fraction of 20%, and heat at 95°C for 1.5 hours;

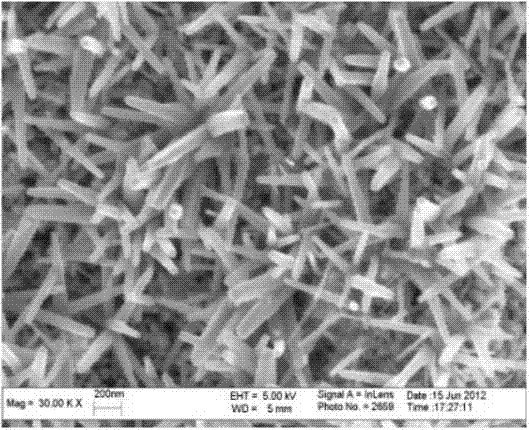

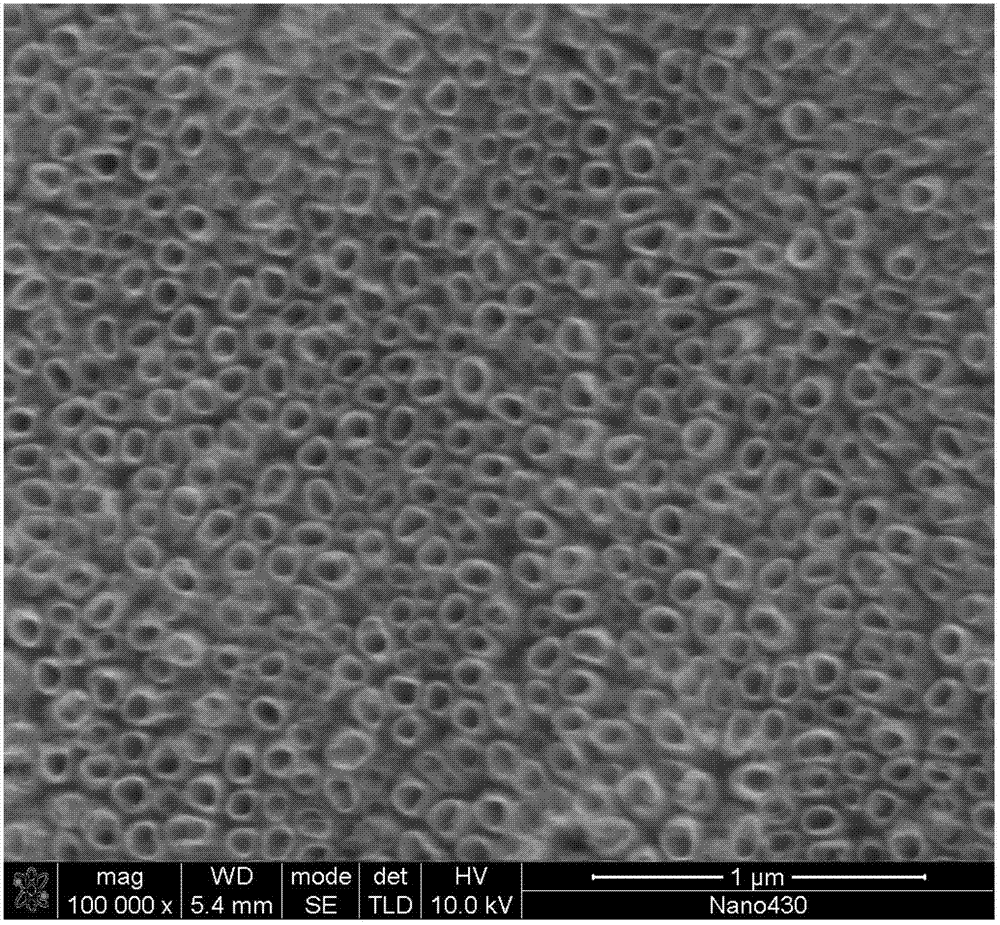

[0038] (2) Preparation of titanium dioxide nanotubes on titanium matrix: the pretreated titanium matrix was fixed on the anode usin...

Embodiment 2

[0042] A preparation method of a DSA electrode for three-dimensional structure analysis of chlorine, comprising the steps of:

[0043] (1) Pretreatment of the titanium substrate: Cut the titanium substrate into a 2cm×3cm sheet sample, and polish it with 350 and 600 mesh sandpaper respectively, so that the surface of the titanium substrate presents a silver-white metallic luster, and then clean it with distilled water ultrasonically ( The ultrasonic power is 200w, the frequency is 40KHz); then the titanium substrate is dissolved and soaked in a sodium hydroxide solution with a mass concentration of 20%, heated at 95°C for 1.5 hours, and then ultrasonically cleaned with distilled water (ultrasonic power is 200w, frequency is 40KHz) ; Soak the titanium substrate with a hydrochloric acid solution with a mass fraction of 20%, and heat at 95° C. for 1.5 hours;

[0044] (2) Preparation of titanium dioxide nanotubes on titanium matrix: the pretreated titanium matrix was fixed on the a...

Embodiment 3

[0049] A preparation method of a DSA electrode for three-dimensional structure analysis of chlorine, comprising the steps of:

[0050] (1) Pretreatment of the titanium substrate: cut the titanium substrate into a 2cm×3cm sheet sample, polish it with 350 and 600 mesh sandpaper, so that the surface of the titanium substrate presents a silver-white metallic luster, and then ultrasonically clean it with distilled water (ultrasonic The power is 200w, the frequency is 40KHz); then the titanium substrate is dissolved and soaked in a sodium hydroxide solution with a mass concentration of 20%, heated at 95°C for 1.5 hours, and then ultrasonically cleaned with distilled water; soaked in a sulfuric acid solution with a mass fraction of 20% Titanium substrate, heated at 95°C for 1.5 hours;

[0051] (2) Preparation of titanium dioxide nanotubes on titanium matrix: the pretreated titanium matrix was fixed on the anode using an anodizing device, the iridium-tantalum electrode was fixed on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com