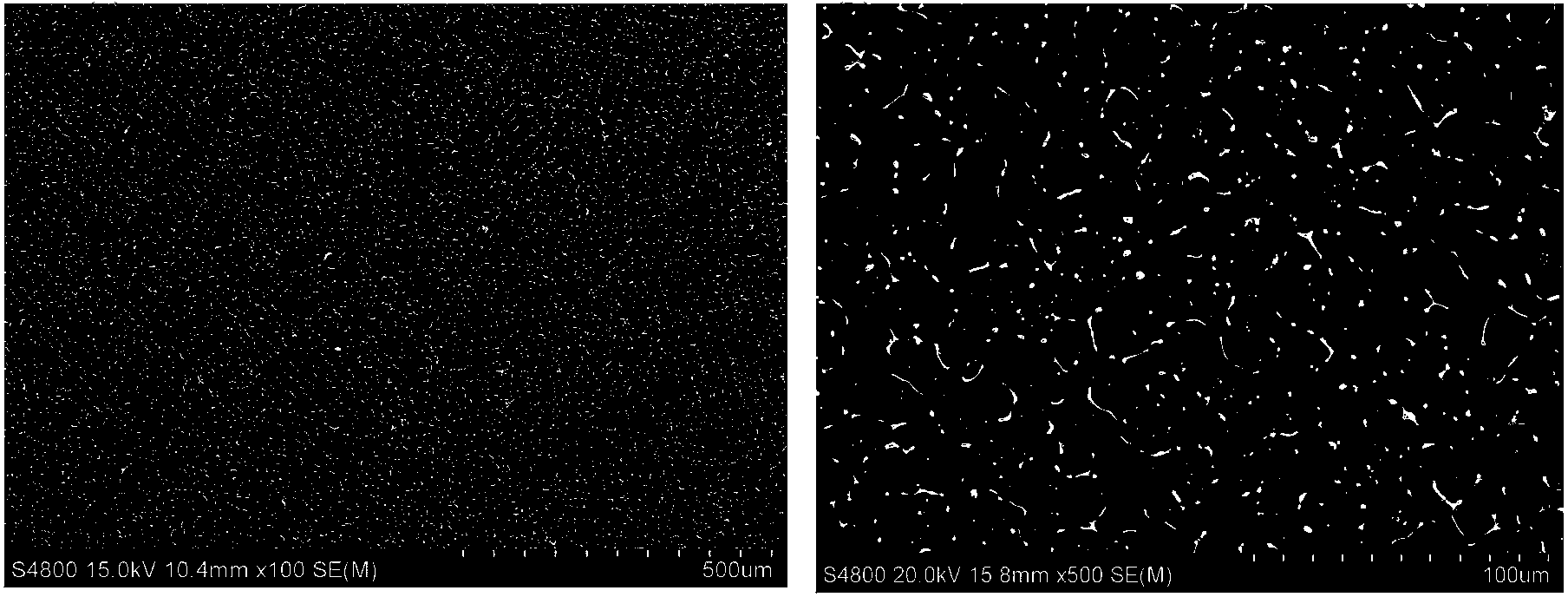

Quasicrystal-strengthened Mg-6Zn-3Y alloy with ultrafine solidification texture and preparation method thereof

A technology of solidified structure and quasicrystal, which is applied in the field of self-generated quasicrystal reinforced alloy and its preparation, can solve the problem of few reports on the size of quasicrystal, and achieve good thermal stability and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

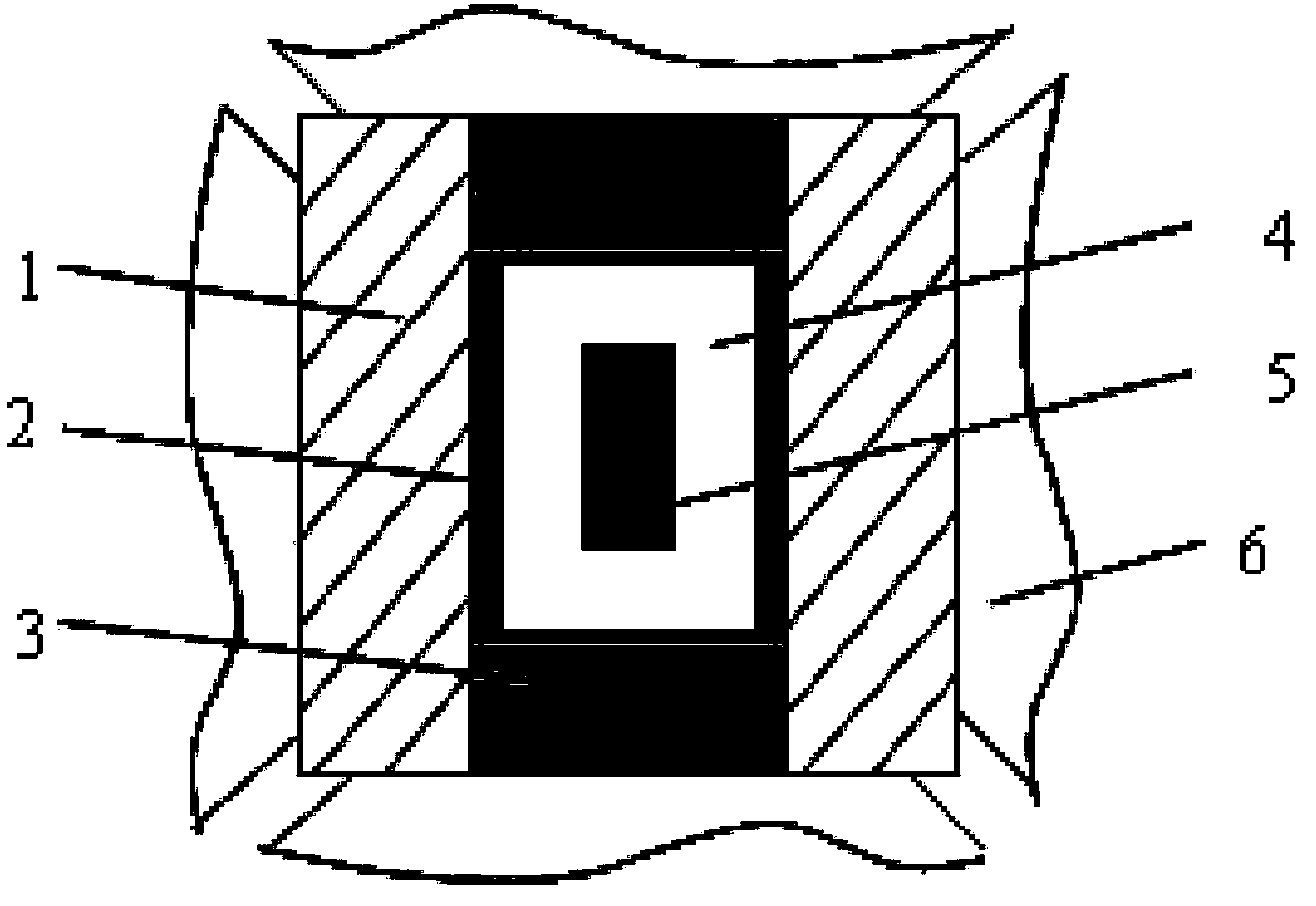

[0030] The technical solutions of the present invention are further described below through examples.

[0031] 1. In terms of melt mass percentage Wt%, weigh Mg: 91.0%, Zn: 6.0%, Y: 3.0%;

[0032] 2. Put the magnesium ingots, zinc ingots, and pure yttrium metal charges in the oven at 200°C in a crucible for preheating and baking;

[0033] 3. Set the heating temperature of the crucible resistance furnace to 780°C. When the crucible temperature rises to 380°C, add magnesium ingots and zinc ingots to the crucible, and start to feed CO2 / SF6 mixed gas as a protective gas, and continue to heat up. After the magnesium ingots and zinc ingots in the crucible are completely melted, add pure yttrium, stir for 2-5 minutes after the pure yttrium is completely melted, keep warm at 780°C for 10-15 minutes after the stirring is completed, and set aside;

[0034]4. Adjust the temperature of the Mg-Zn-Y alloy solution to 760°C, let it stand for 3 to 5 minutes, remove the scum on the surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com