Composite gel electrolyte film for secondary battery, and secondary battery

A gel electrolyte and secondary battery technology, applied in the direction of non-aqueous electrolyte batteries, secondary batteries, electrolytes, etc., can solve the problems of unrecorded composite membranes, etc., and achieve excellent fire resistance, increased ion conductivity, and less coloring Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

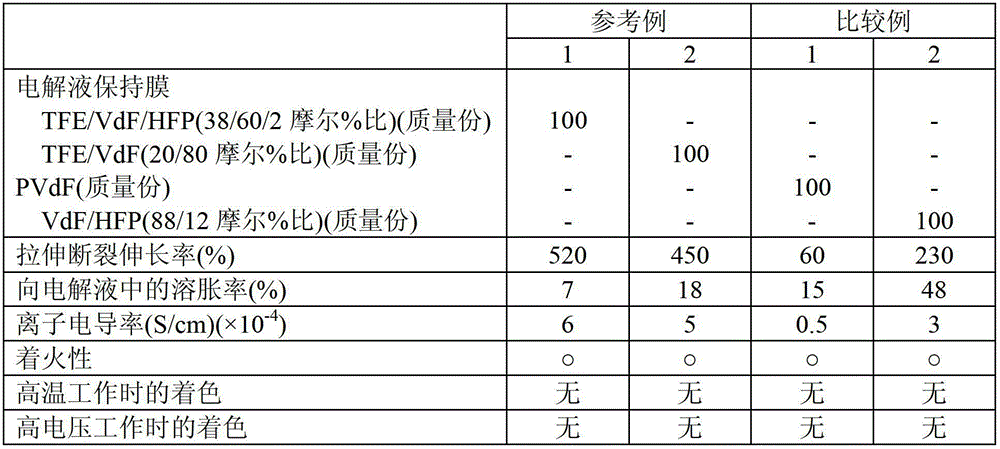

reference example 1

[0080] Dissolve TFE / VdF / HFP (38 / 60 / 2 mol% ratio) copolymer in tetrahydrofuran (THF), coat it on a polyester (PET) film, dry it at 100°C for 15 minutes, and peel it off to make a thickness of 30 μm The electrolyte holding membrane (electrolyte holding membrane 1). The polymer had a melting point of 140°C.

[0081] A dumbbell (5 cm×3 cm short film (booklet)) was produced from the obtained electrolyte solution holding film 1, and the tensile elongation at break was measured with a tensile tester (RTC-1225A manufactured by ORIENTEC). The results are listed in Table 1.

[0082] Furthermore, the electrolyte swelling rate, ion conductivity, and ignitability of the obtained electrolyte holding membrane 1 were examined in the following points. The results are listed in Table 1.

[0083] (electrolyte swelling property)

[0084] The electrolyte holding film was cut into a size of 5mm × 20mm, and added to a solvent containing electrolyte (3 / 7 (volume ratio) of ethylene carbonate and eth...

reference example 2

[0107] In Reference Example 1, the electrolyte holding film 2 produced by the following method was used as the electrolyte holding film, and the tensile elongation at break, electrolyte swelling rate, ion conductivity, ignitability, Coloring during high-temperature operation and coloration during high-voltage operation are studied. The results are listed in Table 1.

[0108] (Fabrication of Electrolyte Retaining Membrane 2)

[0109] A TFE / VdF (20 / 80 mole %) copolymer was dissolved in methyl isobutyl ketone, coated on a PET film, dried at 100° C. for 15 minutes, and peeled off to produce an electrolyte holding membrane 2 with a thickness of 30 μm. The polymer had a melting point of 120°C.

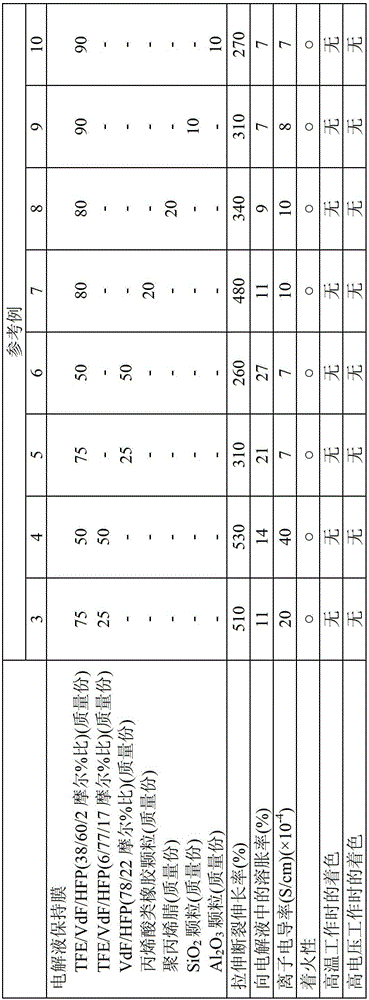

Embodiment 1~6

[0143] In Reference Example 1, except that the electrolyte holding film was not used but the electrolyte holding film produced by the following method was used to cover the separators 1 to 6, the ion conductivity, ignitability, coloring during high-temperature operation, and Coloring at high voltage operation is studied. The results are listed in Table 3.

[0144] (Fabrication of Electrolyte Retaining Membrane Covered Separator 1)

[0145] Dissolve TFE / VdF / HFP (38 / 60 / 2 mol% ratio) copolymer in THF, apply it on a polyethylene separator (thickness 22 μm), and dry it at 80°C for 15 minutes to produce an electrolyte solution Separator 1 covered with a holding film layer (thickness 1 μm) (mass ratio of separator / VdF / TFE-based copolymer in electrolyte holding film layer: about 1 / 0.5).

[0146] (Fabrication of Electrolyte Retaining Membrane Covered Separator 2)

[0147] TFE / VdF / HFP (38 / 60 / 2 mole % ratio) copolymer and TFE / VdF / HFP (6 / 77 / 17 mole % ratio) copolymer rubber are mixed a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com