Bio-based long-carbon-chain semi-alicyclic polyamide-imide PA10I and synthesizing method thereof

A technology of polyamideimide and its synthetic method, which is applied in the field of bio-based long carbon chain semialicyclic polyamideimide PA10I and its synthesis, and can solve the problem of no relevant reports and toxicity of synthetic polyamideimide. , human body and environmental hazards, and achieve the effects of low dimensional stability, convenient operation, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

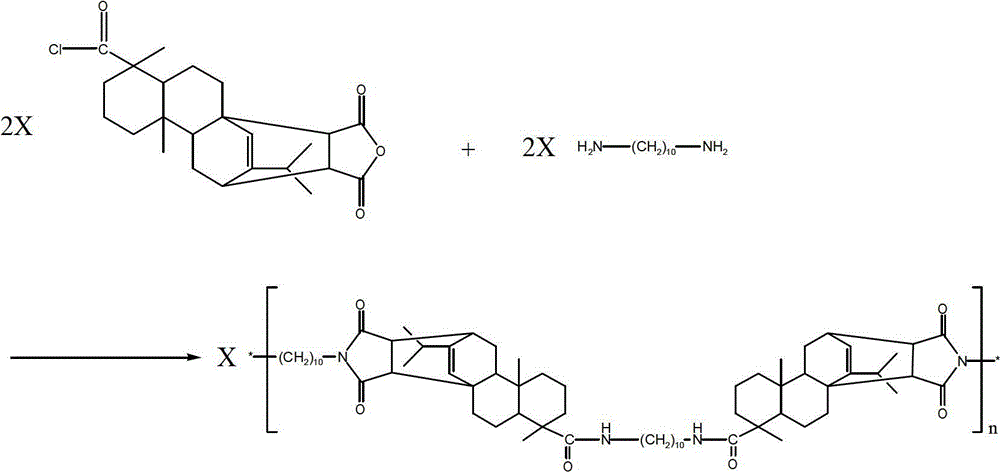

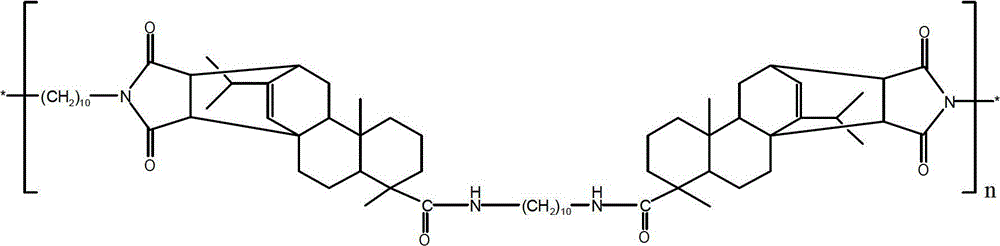

[0027] (1) Preparation of maleopimaric acid chloride

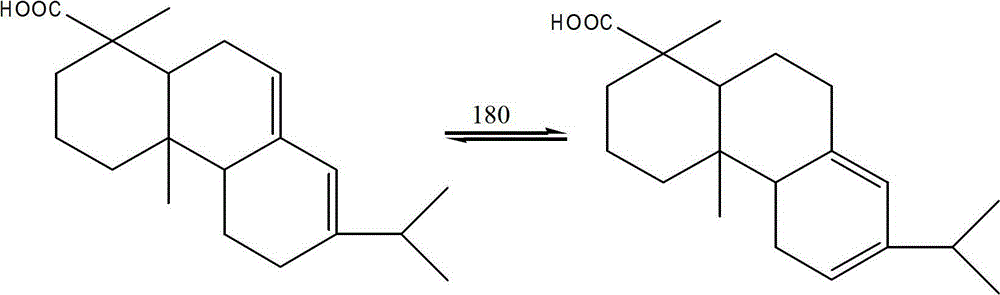

[0028] Gum rosin is a renewable natural chemical raw material, which contains about 90% resin acid and about 10% ester and unsaponifiable substances. The main component of resin acid is abietic acid with conjugated double bonds, and the conjugated double bonds in the molecular structure of abietic acid are not in the same alicyclic ring, so it cannot perform Diels-Alder reaction with double bond compounds such as maleic anhydride, but in At high temperature, abietic acid can be converted into pimaric acid through isomerization equilibrium reaction. Pimaric acid is obtained through Diels-Alder reaction with maleic anhydride to obtain maleopimaric anhydride. Finally, maleopimaric anhydride reacts with thionyl chloride at room temperature to obtain maleopimaric acid chloride.

[0029] Gum rosin was purchased from Guangzhou Lvjin Resin Co., Ltd.

[0030] ①Abietic acid is purified from gum rosin:

[0031] Add 210 parts by w...

Embodiment 1

[0050] Embodiment 1 A kind of synthetic method of bio-based long carbon chain semialicyclic polyamide-imide PA10I

[0051] Include the following steps:

[0052] (1) Using gum rosin and castor oil as raw materials, maleopimaric acid chloride and 1,10-decanediamine were prepared respectively, and vacuum-dried;

[0053] (2) Add the dried maleopimaric acid chloride and 1,10-decanediamine in a mass ratio of 4.190kg: 1.462kg (molar ratio 1:0.85) into the stirred polymerization reactor, vacuumize for 1min, and pass through helium Gas for 30min, so circulated 20 times, so that the reactant exists in the environment under the protection of nitrogen, and the system pressure in the control reactor is 0.3MPa;

[0054] (3) Airtightly heat the reactor to 110° C., control the system pressure in the reactor to 1.1 MPa, keep the reactant at a pressure-holding temperature for 24 hours, and slowly release the gas to normal pressure;

[0055] (4) Reheat to 250° C., keep vacuuming for 24 hours a...

Embodiment 2

[0056] Embodiment 2 A kind of synthetic method of bio-based long carbon chain semialicyclic polyamide-imide PA10I

[0057] Include the following steps:

[0058] (1) Using gum rosin and castor oil as raw materials, maleopimaric acid chloride and 1,10-decanediamine were prepared respectively, and vacuum-dried;

[0059] (2) Add the dried maleopimaric acid chloride and 1,10-decanediamine in a mass ratio of 4.190kg: 1.634kg (molar ratio 1:0.95) into the stirring polymerization reactor, vacuumize for 30min, and pass nitrogen gas 1min, such cycle 1 time, so that the reactants exist in the environment under the protection of nitrogen, control the system pressure in the reactor to 0.1MPa;

[0060] (3) Airtightly heat the reactor to 140°C, and adjust the stirring speed of the polymerization reactor to 500r / min, control the system pressure in the reactor to 1.3MPa, keep the temperature and pressure of the reactant for 0.5 hours, and slowly release the gas to normal pressure;

[0061] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com