Device for growing zinc oxide crystal

A technology of zinc oxide and crystals, applied in the field of devices for growing zinc oxide crystals, which can solve the problems of difficult growth process control and complex growth device structure, and achieve the effects of reducing production costs, easy control of the growth process, and high growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

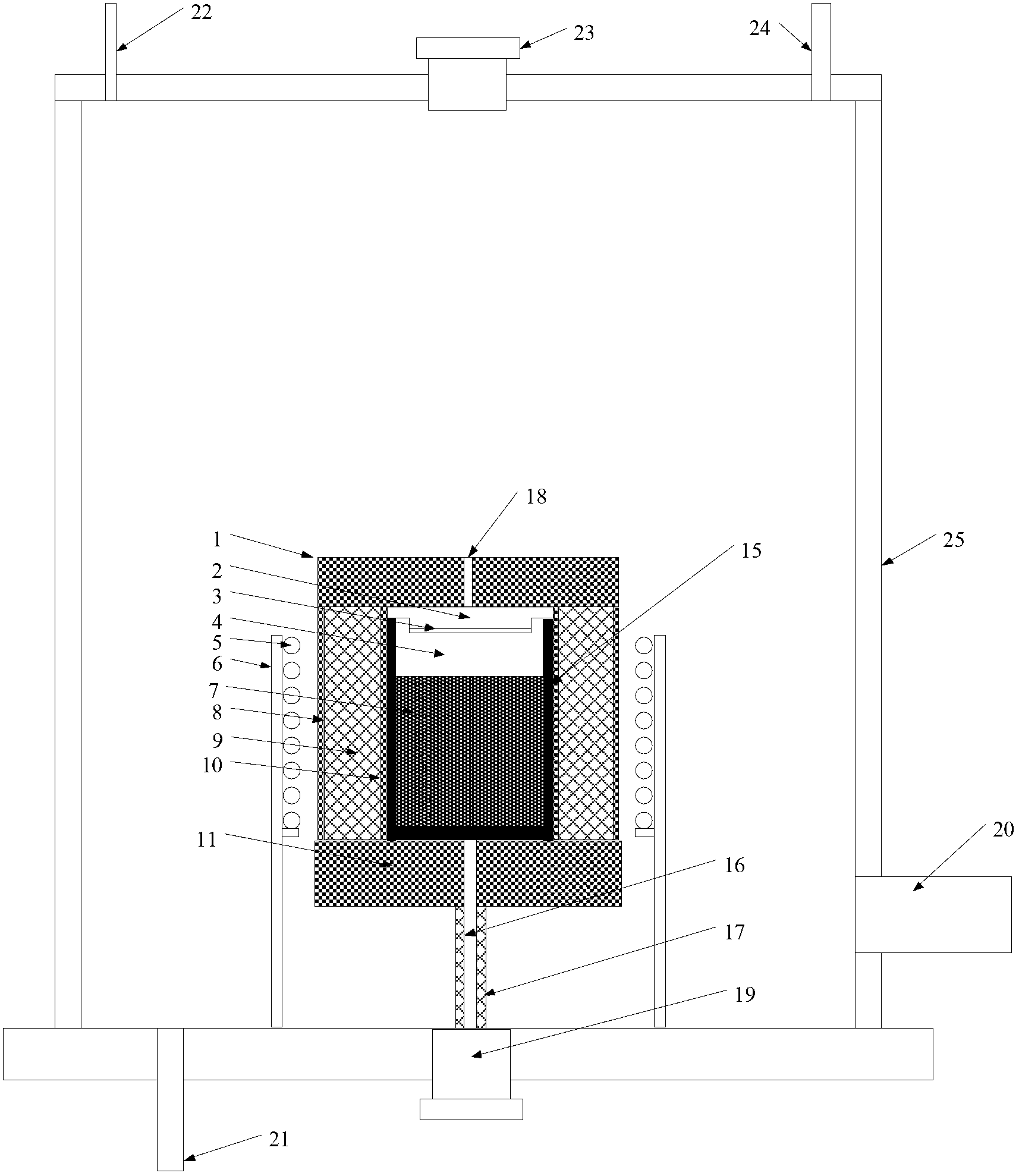

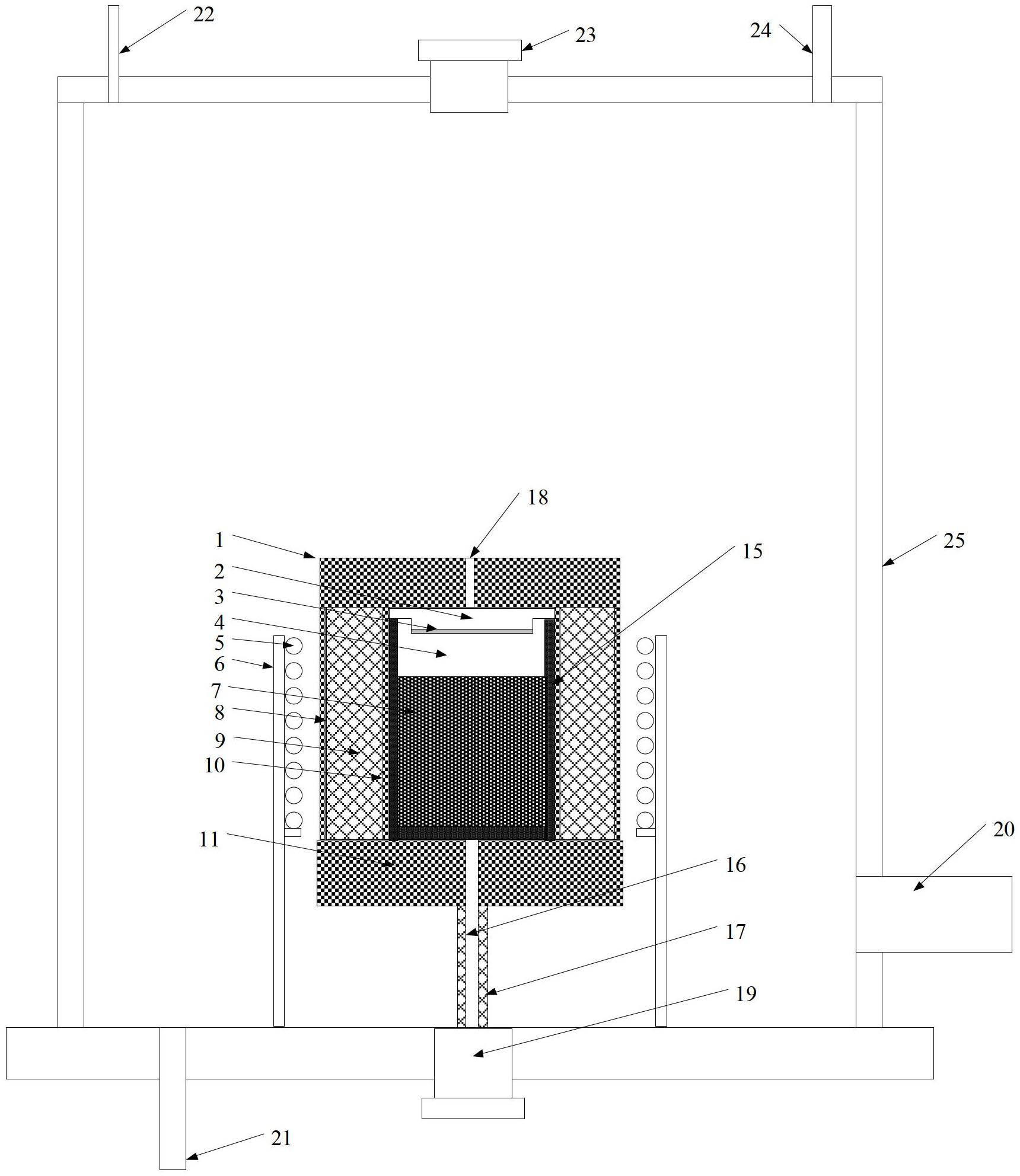

[0019] Example 1, see figure 1 , a device for growing zinc oxide crystals is a single crucible induction heating type, including a heater 15 and a growth chamber 4, the growth chamber 4 is arranged on a corundum support 17 in the vacuum chamber 25 and is heated by the heater 15, the growth chamber 4 Zinc oxide powder 7 is inside, and an insulation layer 1 is provided outside the growth chamber 4 . The water-cooled induction coil 5 is fixed on the coil support 6 and built in a vacuum chamber 25. The vacuum chamber 25 is made of double-layer stainless steel with water interlayer, and the bottom is provided with a cooling water input port 21, and the top is provided with a cooling water output port 24. 25 is provided with a protective gas inlet 22 and an air extraction port 20; the iridium crucible or zirconium diboride crucible doubles as a heater 15 and is covered with an upper top, a lower bottom insulation pad, an outer insulation barrel 8, an inner insulation barrel 10 and ...

Embodiment 2

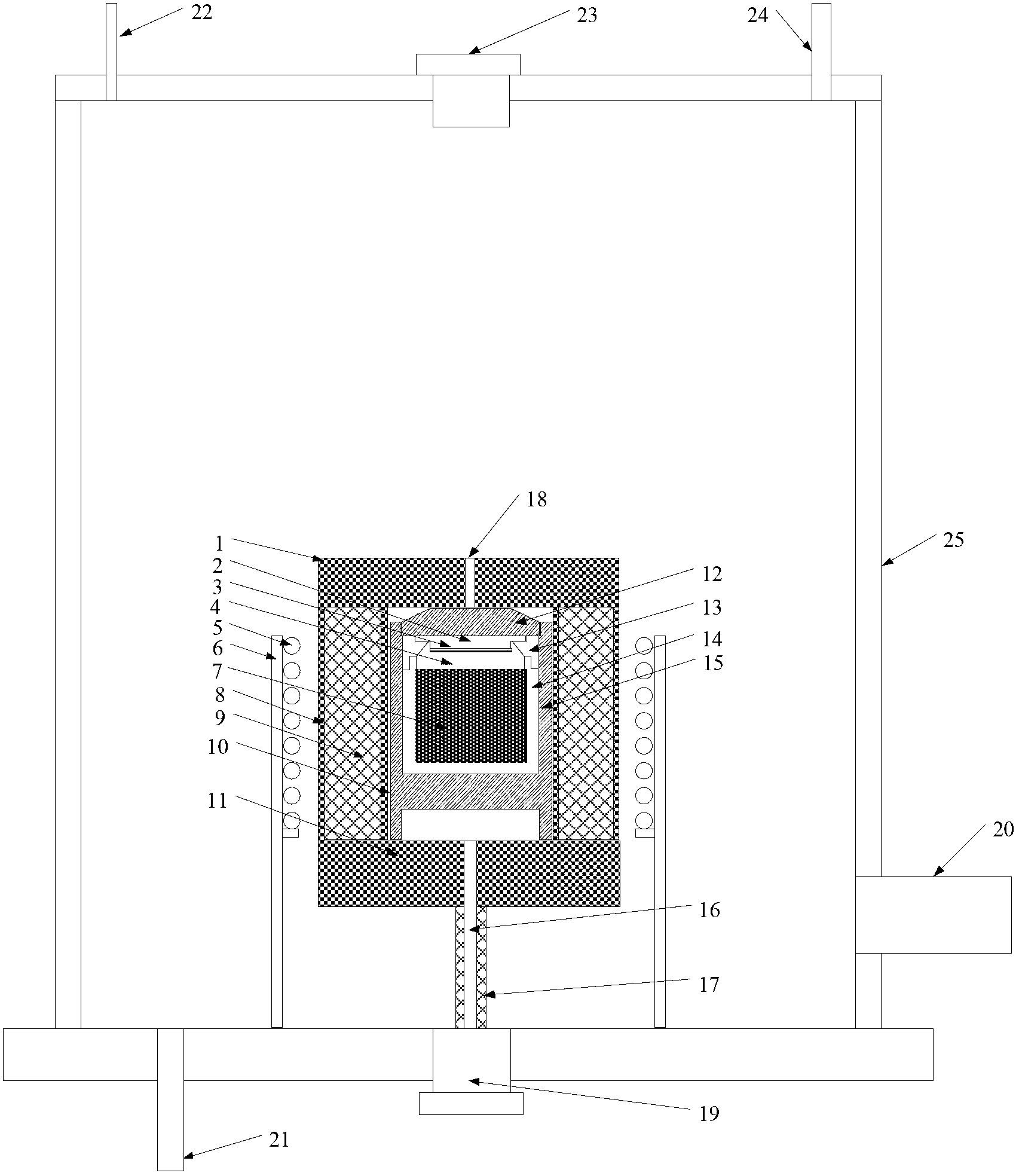

[0020] Example 2, see figure 2 , a device for growing zinc oxide crystals is a double-crucible induction heating type, including a heater 15 and a growth chamber 4, the growth chamber 4 is arranged on a corundum support 17 in the vacuum chamber 25 and is heated by the heater 15, the growth chamber 4 Zinc oxide powder 7 is inside, and an insulation layer 1 is provided outside the growth chamber 4 . The upper heater 15 is an upper heater 12 . The water-cooled induction coil 5 is fixed on the coil support 6 and built in a vacuum chamber 25, the vacuum chamber 25 is made of double-layer stainless steel with water interlayer and is provided with a cooling water input port 21 and a cooling water output port 24 and a protection valve at its upper and lower parts respectively. The gas inlet 22 and the gas extraction port 20; the alumina crucible composed of the upper crucible 13, the lower crucible 14 and the crucible cover 2 is coaxially installed in the zirconium diboride heater 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com