Microarc-oxidized coating silylation fluid and hole sealing method thereby

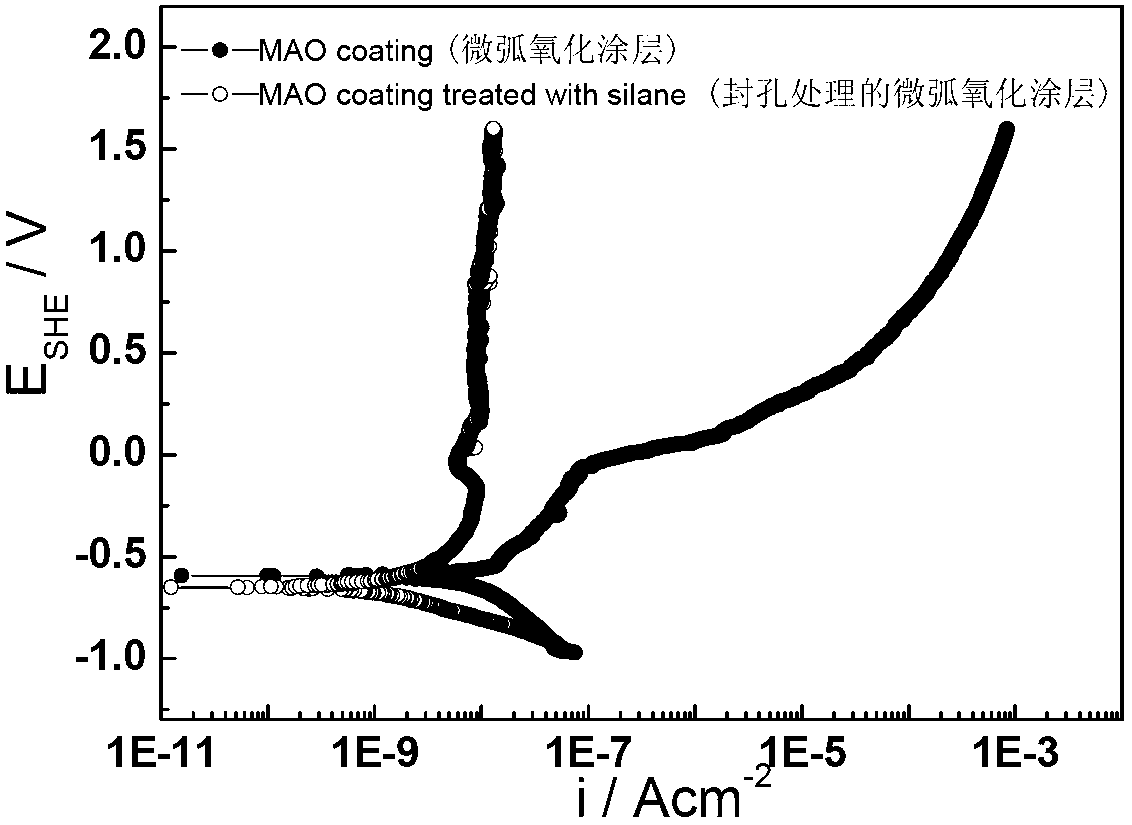

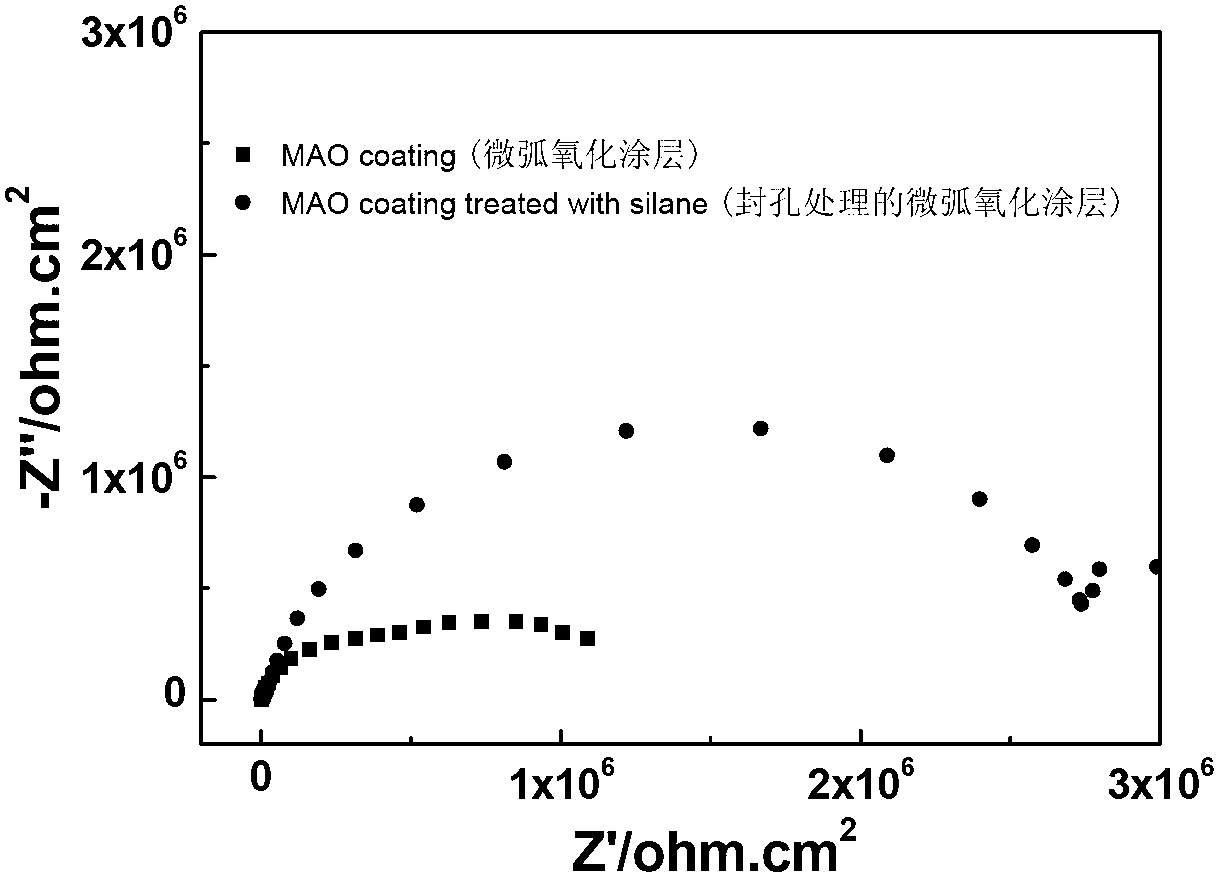

A technology of silanization treatment and micro-arc oxidation, which is applied in the direction of anodic oxidation and metal material coating technology, etc., can solve the problems of small coverage, inability to meet the application requirements of actual components, and limited number of micro-arc oxidation coating sealing treatments , to achieve the effect of low price, promotion of engineering application, and rich varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Taking epoxy silane coupling agent KH-560 (γ-(2,3-glycidoxy)propyltrimethoxysilane) as an example to describe the method of sealing pores of aluminum alloy micro-arc oxidation coating by silanization treatment Implementation process.

[0033] ① Preparation of hydrolysis solution: add 60ml of methanol to 180ml of deionized water, place on a magnetic stirrer and stir evenly, then add 60ml of silane coupling agent KH-560, stir evenly; add dropwise acetic acid to adjust the pH value of the solution to 5, Ultrasonic vibration was used for 30 minutes to make the solution uniformly mixed; the above solution was left to stand at room temperature for 72 hours to prepare 300 ml of a hydrolyzed solution with a silane coupling agent concentration of 20%;

[0034] ② Put the aluminum alloy micro-arc oxidation coating sample with a size of 50×50×5mm into the above-mentioned silane hydrolysis solution for 20 minutes, take it out and air dry it in the air;

[0035] ③After the sample is...

Embodiment 2

[0040] Taking aminosilane coupling agent KH-550 (γ-aminopropyltriethoxysilane) as an example to describe the implementation process of sealing holes in magnesium alloy MAO coating by silanization treatment.

[0041] The volume ratio of water, ethanol, and KH-550 is prepared as 6:1:1, that is, a hydrolysis solution with a silane coupling agent concentration of 12.5%, and a silane film is prepared on the surface of the magnesium alloy micro-arc oxidation coating according to the steps described in Example 1. Experiments show that after the sealing treatment, the neutral salt spray corrosion resistance time of the magnesium alloy micro-arc oxidation coating is increased by more than 3 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com