Method for improving dispersion property of nanosilicon grinding fluid

A technique of dispersing performance and abrasive liquid, which is applied in the treatment of dyed low-molecular organic compounds, dyed high-molecular organic compounds, and fibrous fillers. The effect of storage performance and processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

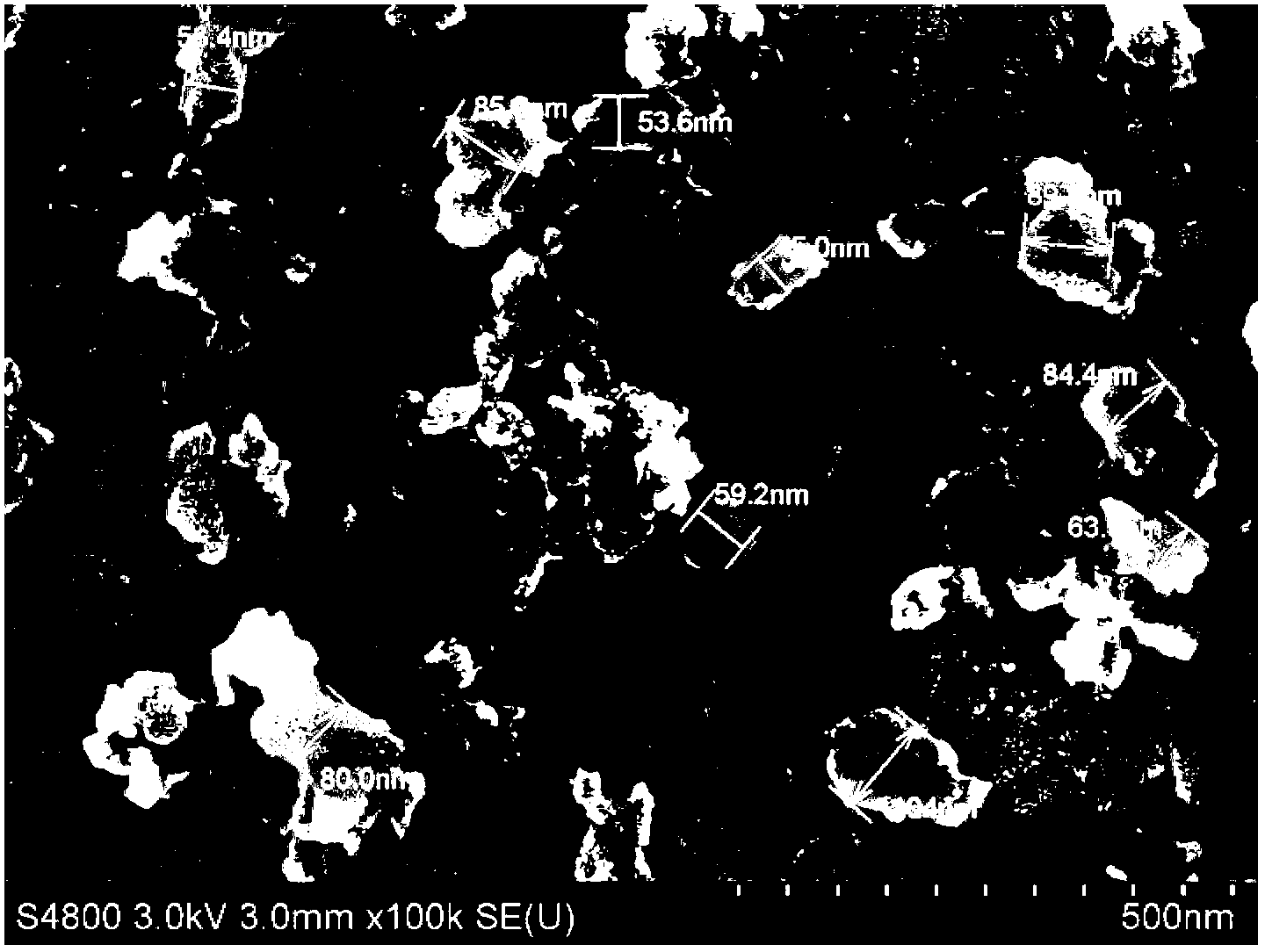

Embodiment 1

[0034] Example 1, the coarse silicon powder with a particle size of 60 μm and a silicon content of 95% is poured into a stirring mill, then acetone is added to adjust the solid content to 25%, the rotating speed is 1200r / min, and the rough grinding is carried out for 25 hours. After rough grinding, the particle size is 1 μm. Transfer the coarsely ground silicon grinding liquid to a horizontal nano-ceramic structure sand mill, the mass ratio of the grinding media to the silicon powder is 3:1, add a dispersion medium to ensure that the solid content in the sand grinding process is 17%, and then carry out Sanding, the sanding time is 37h, the rotation speed is 2200r / min, and the silicon grinding liquid after sanding is obtained. Add the strong electrolyte anion dispersant sodium lignosulfonate accounting for 1.2% by weight of the silicon powder to the silicon grinding liquid after sanding, the rotation speed is 500r / min, and the time is 20min to obtain the nano-silicon grinding l...

Embodiment 2

[0037] Example 2, pour the coarse silicon powder with a particle size of 60 μm and a silicon content of 95% into the stirring mill, then add toluene to adjust the solid content to 25%, the rotating speed is 1500r / min, and the rough grinding is carried out for 25 hours. After the rough grinding, the particle size is 1 μm. Transfer the coarsely ground silicon grinding liquid to a horizontal nano-ceramic structure sand mill, the mass ratio of grinding medium to silicon powder is 3.5:1, add dispersion medium to ensure that the solid content in the sand grinding process is 17%, and then carry out Sanding, the sanding time is 37h, the rotation speed is 2200r / min, and the silicon grinding liquid after sanding is obtained. Add the strong electrolyte anion dispersant sodium lignosulfonate accounting for 1.2% by weight of the silicon powder to the silicon grinding liquid after sanding, the rotation speed is 2000r / min, and the time is 30min to obtain the nano-silicon grinding liquid. Pl...

Embodiment 3

[0039] Example 3, the coarse silicon powder with a particle size of 50 μm and a silicon content of 95% is poured into the stirring mill, and then ethanol is added to adjust the solid content to 10%, the rotating speed is 1500r / min, and the rough grinding is carried out for 10 hours. After the rough grinding, the particle size is 3 μm. Transfer the coarsely ground silicon grinding liquid to a horizontal nano-ceramic structure sand mill, the mass ratio of the grinding media to the silicon powder is 3:1, add a dispersion medium to ensure that the solid content in the sand grinding process is 10%, and then carry out Sanding, the sanding time is 80h, the number of revolutions is 2700r / min, and the silicon abrasive liquid after sanding is obtained. Add the strong electrolyte anion dispersant sodium lignosulfonate accounting for 0.1% by weight of the silicon powder to the silicon grinding liquid after sanding, the rotation speed is 2500r / min, and the time is 20min to obtain the nano-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com