Pillared modified kieselguhr for adsorbing Pb<2+> and/or Cd<2+> and preparation method and application of pillared modified kieselguhr

A diatomite and modification technology is applied in the field of environmental protection adsorption material preparation to achieve the effects of simple process, low energy consumption and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

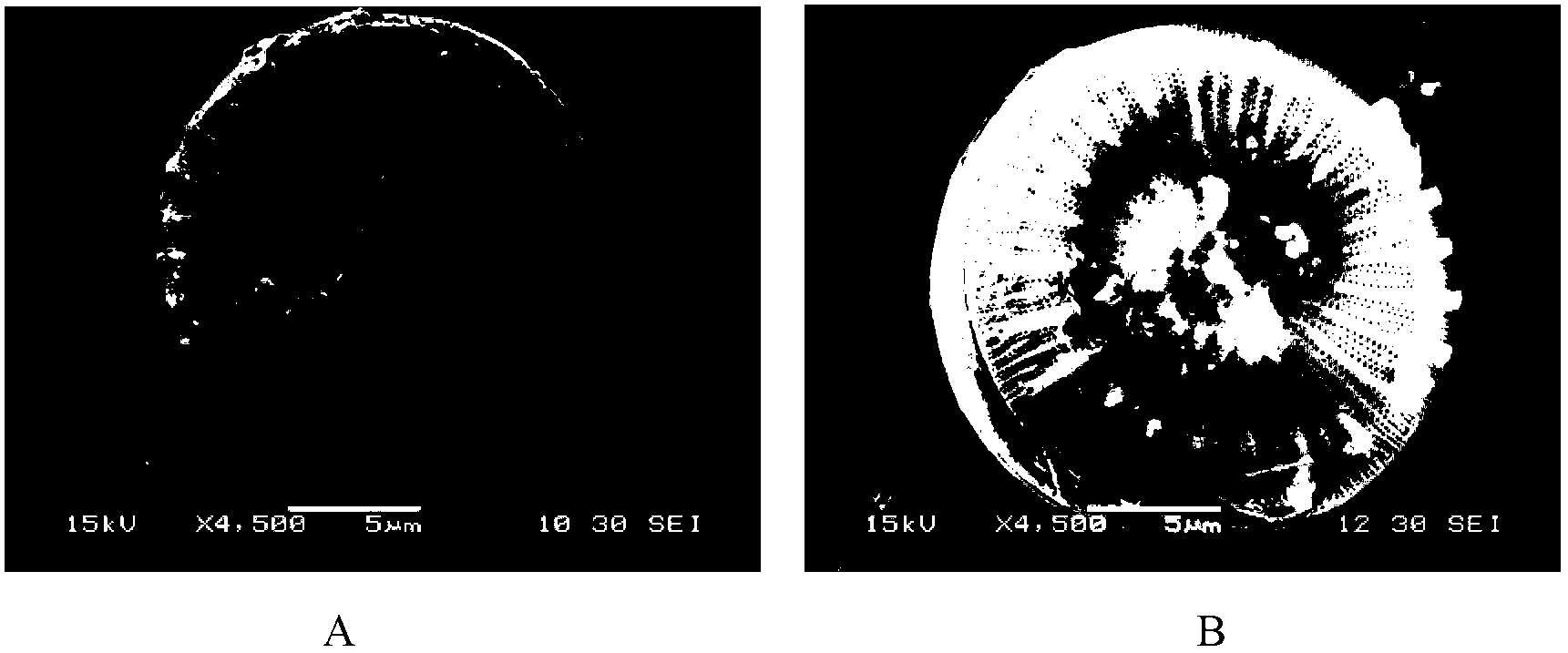

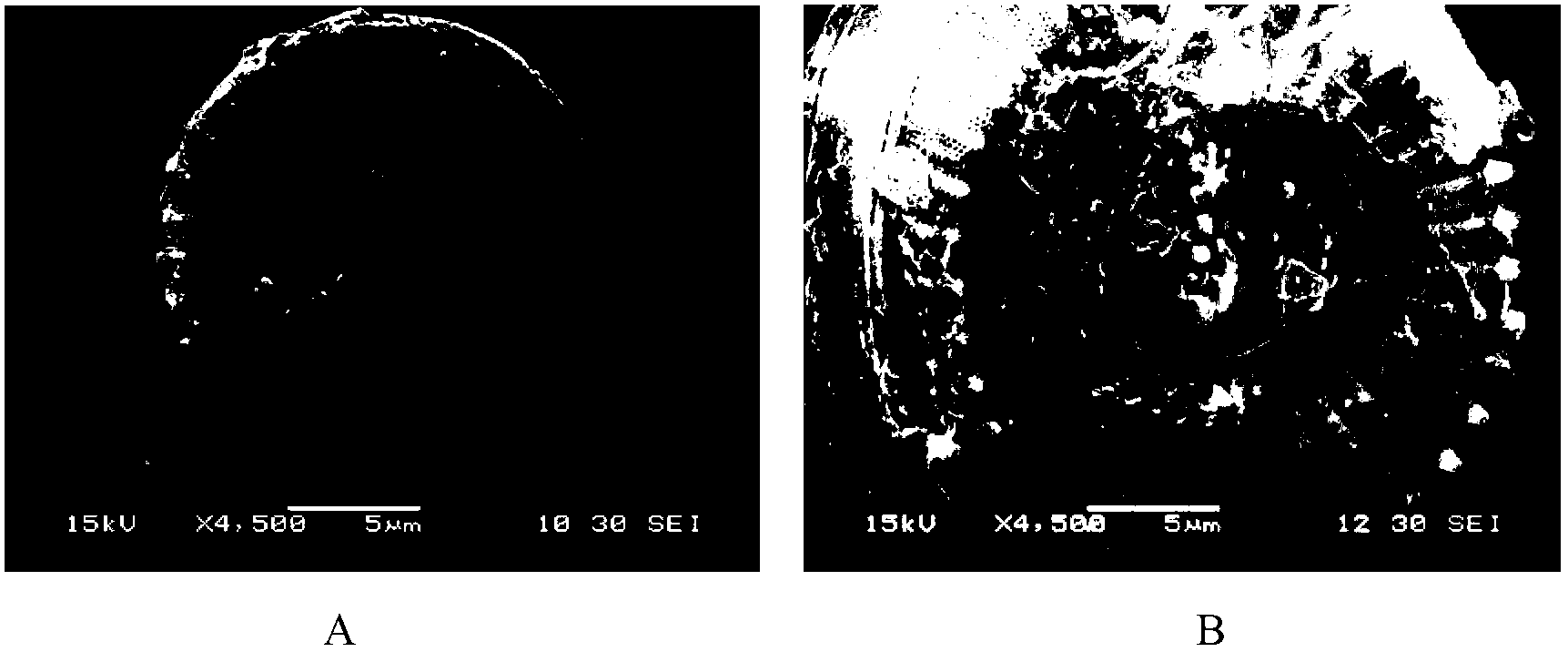

Image

Examples

Embodiment 1

[0034] Embodiment 1, based on the Pb in the adsorption solution 2+ When applying the method of the present invention to prepare the pillared modified diatomite, the specific implementation steps are as follows.

[0035] (1) Preparation of materials: Take an appropriate amount of diatomite raw ore to grind in a mortar, pass through a 100-mesh nylon sieve; take an appropriate amount of sieved diatomite in a beaker, add concentrated sulfuric acid with a volume fraction of 98%, and stir for 12 hours. Stand still for 12 hours to obtain purified diatomite; take a certain concentration of AlCl 3 The aqueous solution is placed in a beaker, and the molar ratio [OH-] / [Al 3+ ]=2.4 ratio, measure the corresponding amount of sodium carbonate solution, slowly drop into AlCl 3 In aqueous solution; stirring continuously, the reaction temperature is set to 60°C, and the reaction time is set to 2h; after the reaction is completed, the solution is moved into an ultrasonic scrubber of a certain...

Embodiment 2

[0061] Embodiment 2, based on the Cd in the adsorption solution 2+ When applying the present invention to prepare pillared modified diatomite, the specific implementation steps are as follows.

[0062] (1) Preparation of materials: the method steps are the same as in Example 1.

[0063] (2) Determination of modification conditions: the method steps are the same as in Example 1. See Table 10-15 for relevant data.

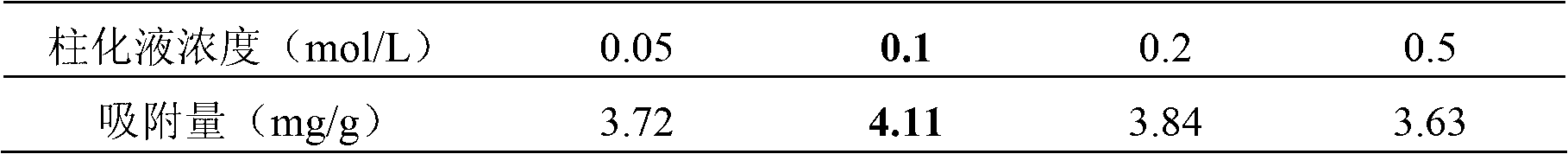

[0064] Table 10 Effect of concentration of column liquid on adsorption capacity of modified diatomite

[0065]

[0066] Table 11 Effect of [Al] / soil molar mass ratio on the adsorption capacity of modified diatomite

[0067]

[0068] Table 12 Effect of reaction temperature on the adsorption capacity of modified diatomite

[0069]

[0070] Table 13 Effect of reaction time on the adsorption capacity of modified diatomite

[0071]

[0072] Table 14 Effect of activation temperature on the adsorption capacity of modified diatomite

[0073]

[0074] Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com