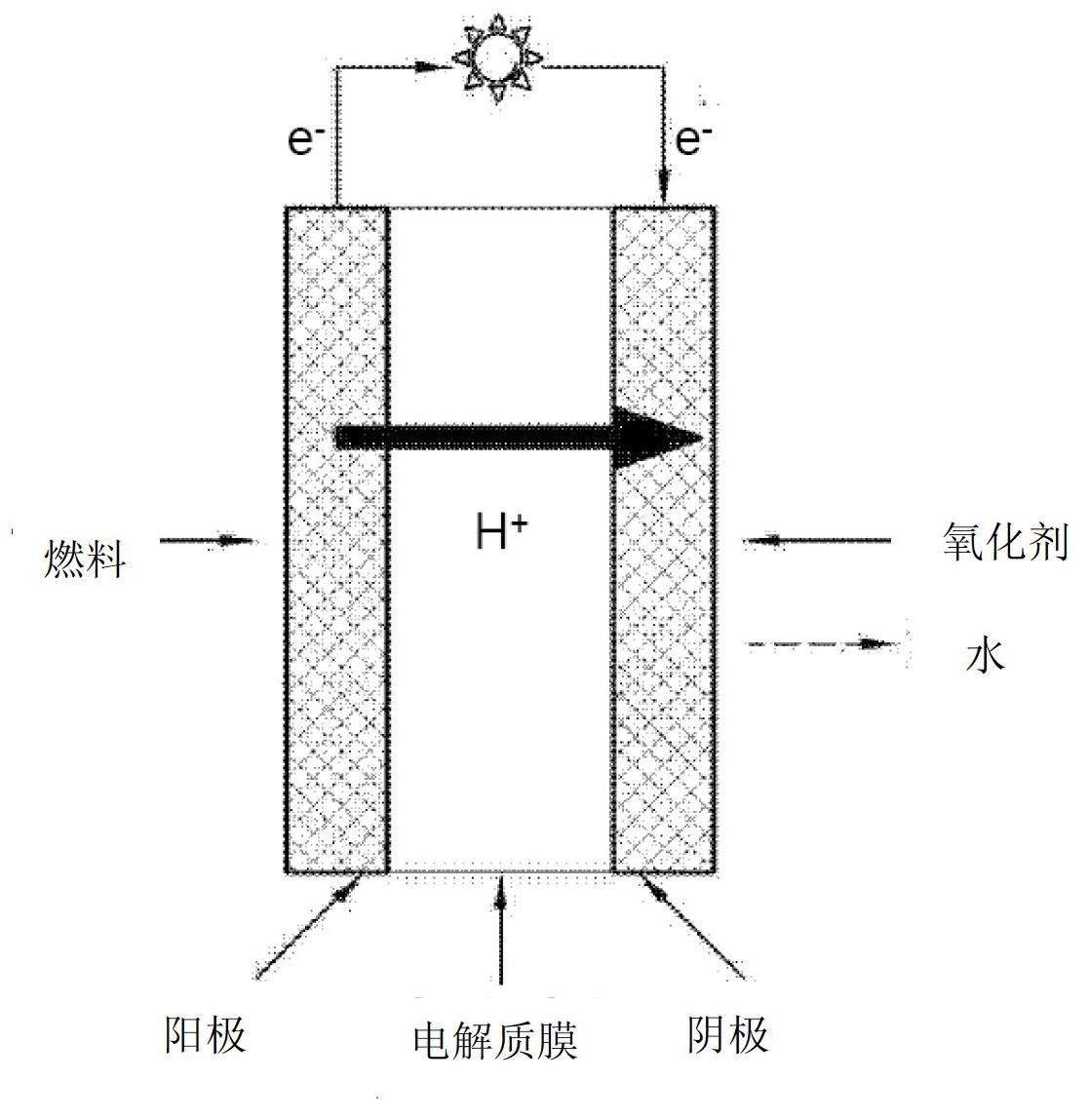

Macromolecular electrolyte membrane for a fuel cell, and a membrane electrode binder material and a fuel cell comprising the same

An electrolyte membrane and fuel cell technology, which is applied in the parts of fuel cells, fuel cells, solid electrolyte fuel cells, etc., can solve the problems of no performance and hindering the mixing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

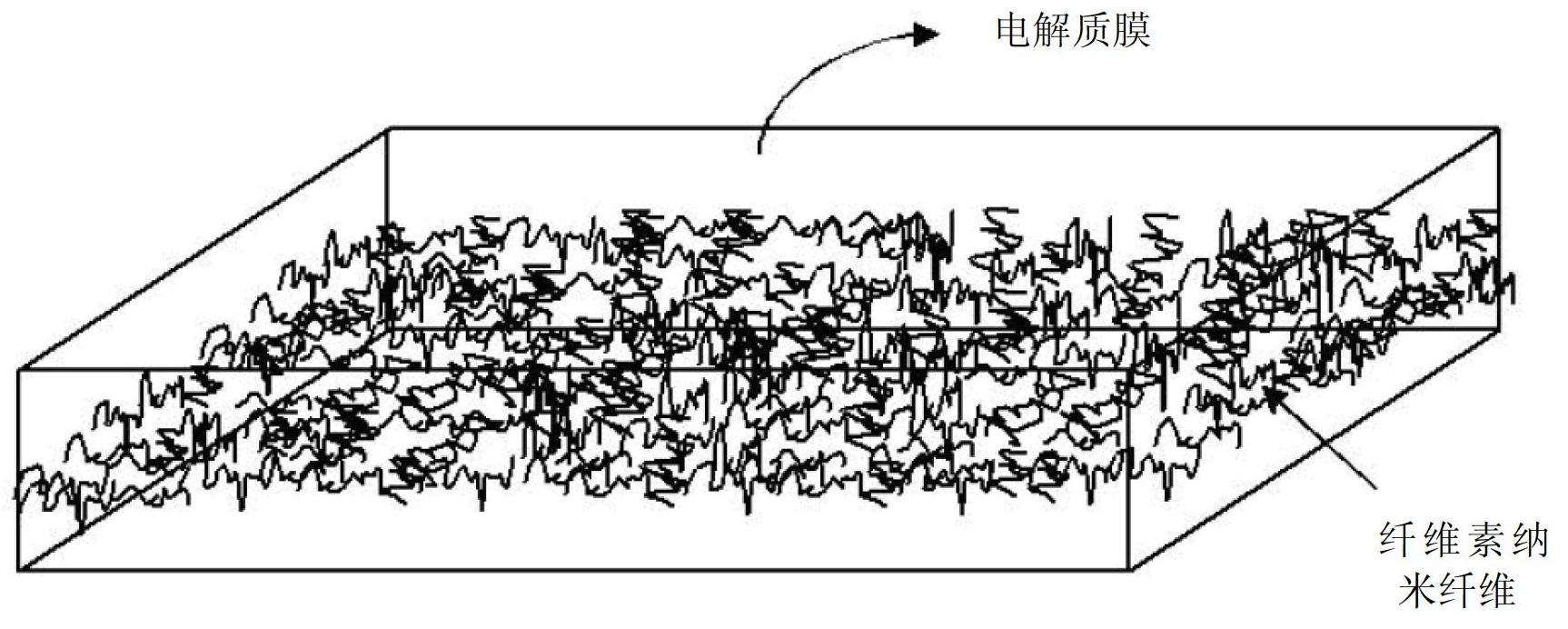

[0061] Ethylcellulose powder (Dow Inc., ETHOCELTM, substituted with 48-49.5% ethyl) was dispersed in DMSO, and the cellulose was dissociated (decompose) by processing several times in solution using a microfluidizer. ) to form nanofibers. The thus prepared ethylcellulose nanofibers have a diameter of 10-100 nm and a length of 1-10 μm.

[0062] 0.2 parts by weight of the cellulose nanofiber and 99.8 parts by weight of sulfonated polyetheretherketone were added to 2,000 parts by weight of DMSO as a solvent, followed by uniform dissolution. The above solution was coated on a substrate by solution casting using a film applicator to form a film with a thickness of 20 μm, the temperature was slowly raised to 80° C., the film was dried for about 24 hours, and then dried at 120° C. for 24 hours, Proton exchange was performed using sulfonic acid treatment to produce the final polymer electrolyte membrane.

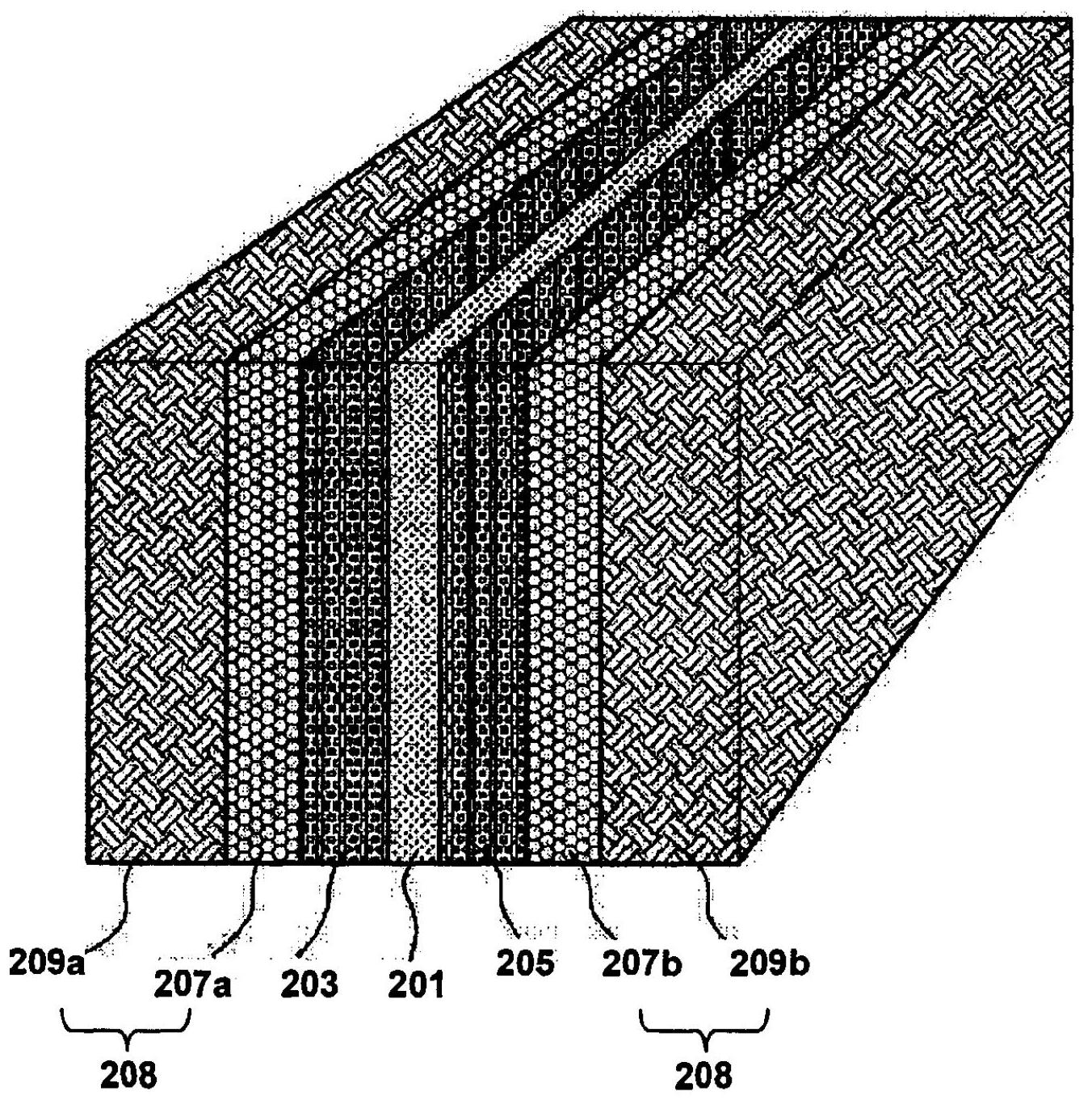

[0063] Dissolve the carbon-supported platinum catalyst (platinum-supported ca...

Embodiment 2

[0065] Except for using 99 parts by weight of sulfonated polyether ether ketone and 1 part by weight of ethyl cellulose nanofibers, a polymer electrolyte membrane, a membrane electrode assembly and a fuel cell were prepared in the same manner as in Example 1.

Embodiment 3

[0067] Except for using 97 parts by weight of sulfonated polyether ether ketone and 3 parts by weight of ethyl cellulose nanofibers, a polymer electrolyte membrane, a membrane electrode assembly and a fuel cell were prepared in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com