Carbon microparticle and process for production thereof

A manufacturing method and technology of carbon particles, applied in chemical instruments and methods, final product manufacturing, carbon preparation/purification, etc., can solve the problems of carbon particles, narrow particle size distribution, and spherical particles, etc., to achieve coating Excellent cloth thickness uniformity, reduced coating unevenness, and the effect of easy particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0451] Next, the present invention will be described in more detail based on examples. The present invention is not limited by these Examples. In the examples, the assays used are as follows.

[0452] (1) Determination of weight average molecular weight

[0453] The weight average molecular weight is a molecular weight calculated by comparing with a calibration curve using polystyrene using gel permeation chromatography.

[0454] Device: LC-10A series manufactured by Shimadzu Corporation

[0455] Column: KD-806M manufactured by Showa Denko Co., Ltd.

[0456] Mobile phase: 10 mmol / L lithium bromide / dimethylformamide solution

[0457] Flow rate: 1.0ml / min

[0458] Detection: Differential Refractometer

[0459] Column temperature: 40°C.

[0460] (2) Calculation method of number average particle size, volume average particle size and particle size distribution

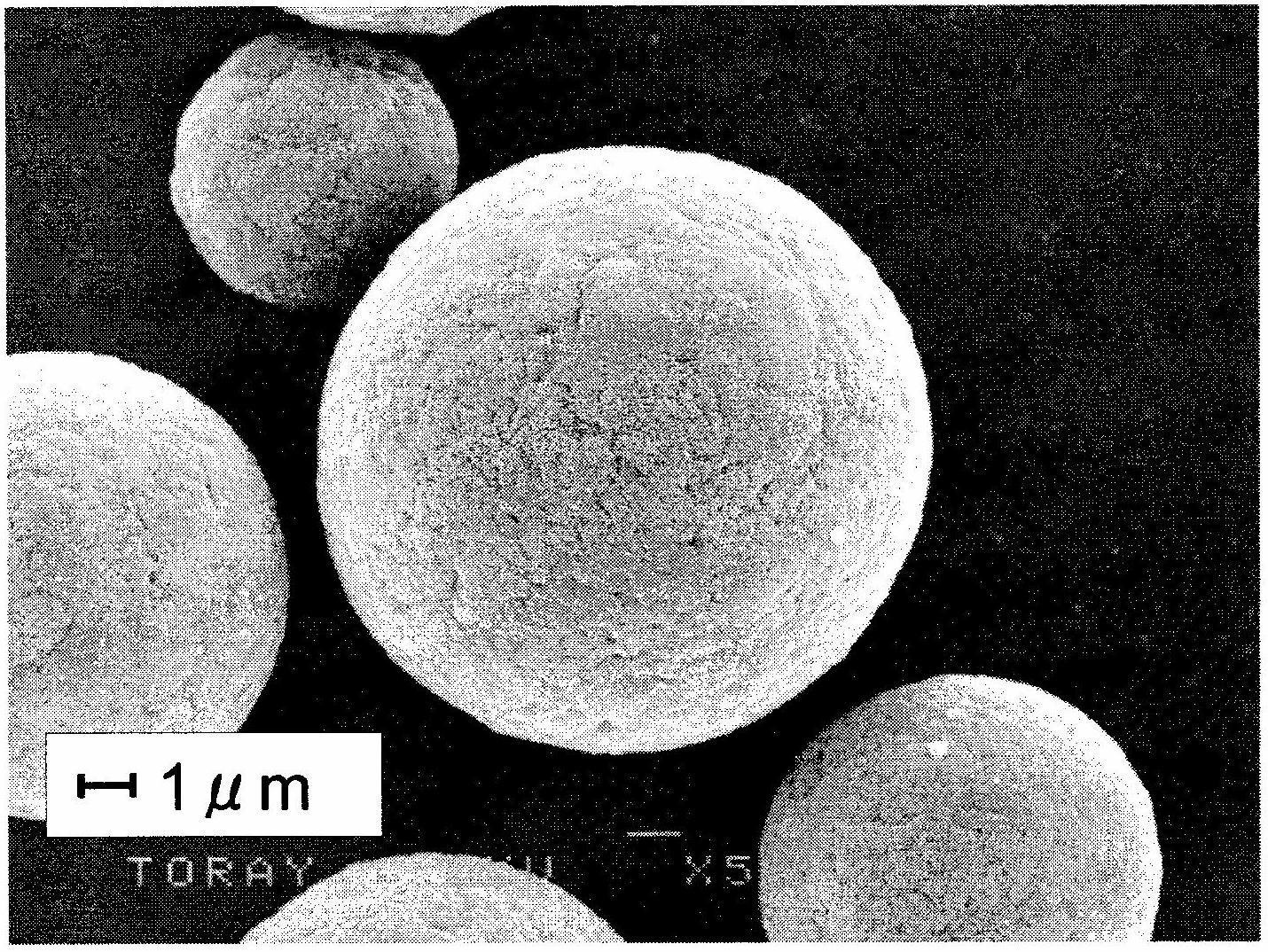

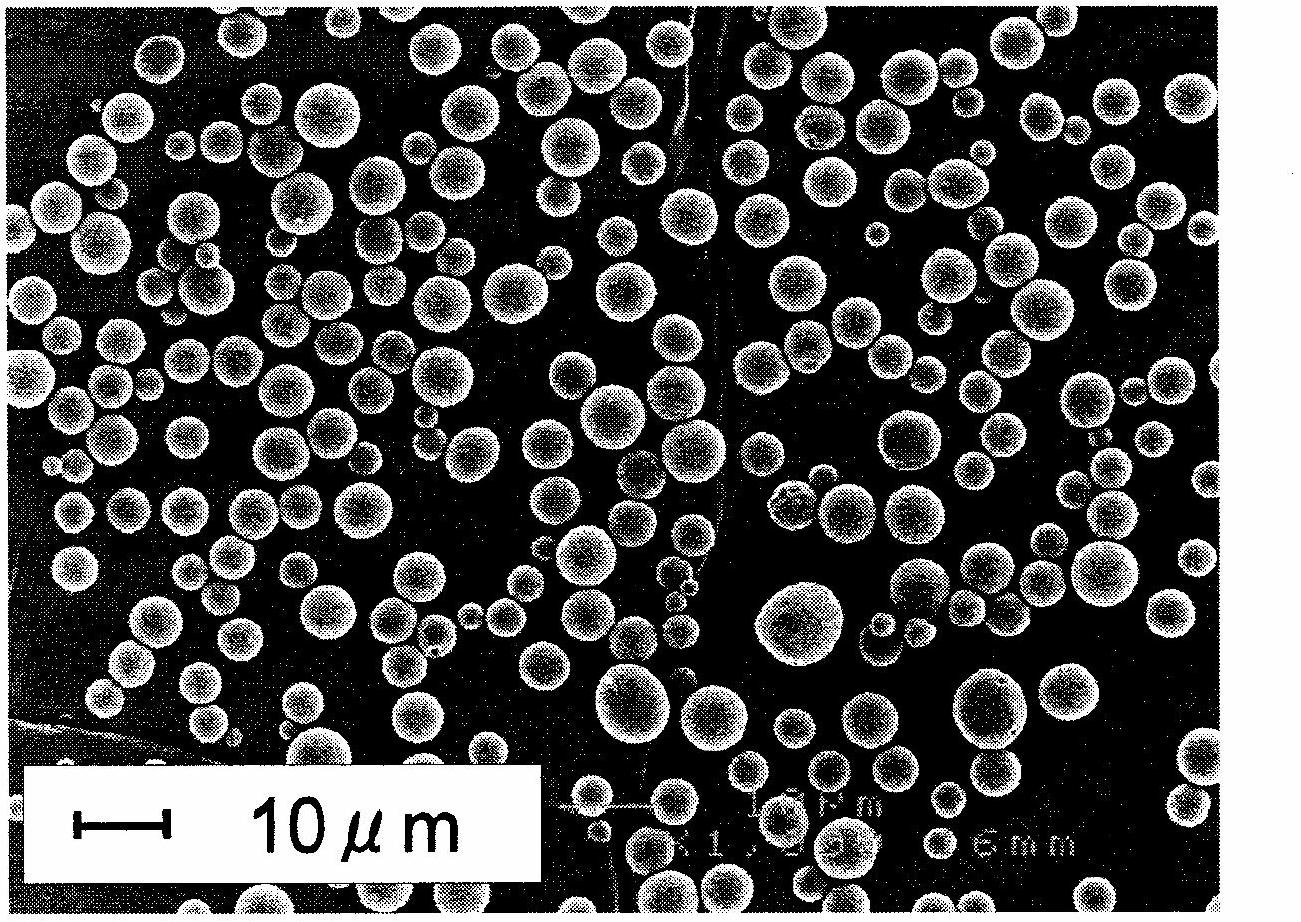

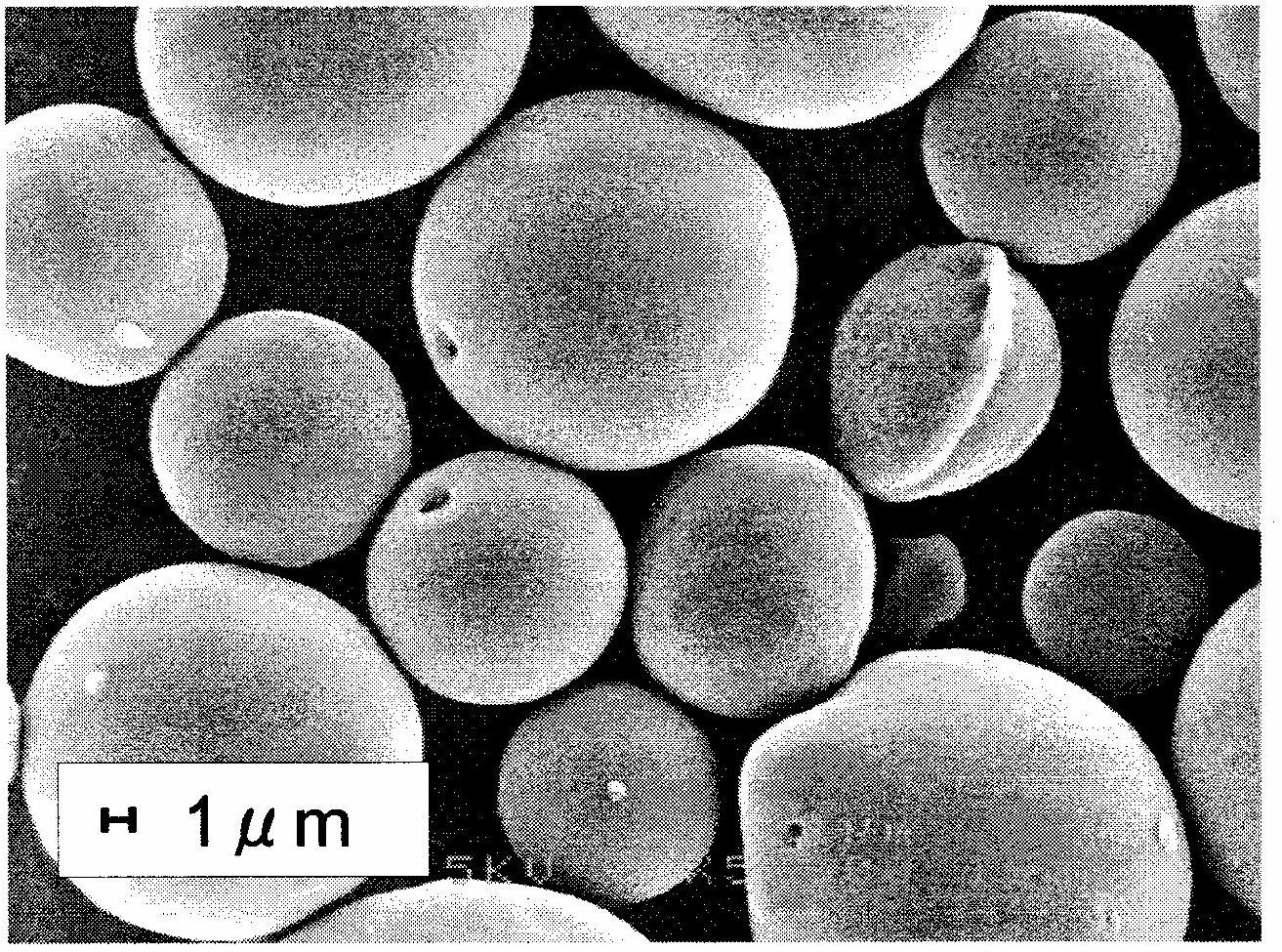

[0461] The particles were observed using a scanning electron microscope (Scanning Electron Microscope JSM-6301NF...

manufacture example 1

[0480] In a reaction vessel equipped with a reflux tube and a stirring paddle, dissolve 99 parts by mass of acrylonitrile and 1 part by mass of itaconic acid in 400 parts by mass of dimethyl sulfoxide, and then add 0.5 parts by mass of benzyl peroxide acyl, heated to 70°C and maintained for 6 hours to carry out polymerization, thereby obtaining a polyacrylonitrile solution. The solution had a weight average molecular weight of 530,000. Add 172 parts by mass of polyvinyl alcohol (Nippon Synthetic Chemical Industry Co., Ltd.'s "Goosenol (registered trademark)" GL-05, weight average molecular weight 10,600, SP value 32.8 (J / cm2) to this solution 3 ) 1 / 2 ), 2776 parts by mass of dimethyl sulfoxide, heated at 80° C., and stirred until all the polymers were dissolved. After the temperature of the system was returned to room temperature, 1500 parts by mass of ion-exchanged water as a poor solvent was added dropwise at a rate of 25 parts by mass / min via a liquid delivery pump to pre...

manufacture example 2

[0482] In a reaction vessel equipped with a reflux tube and a stirring paddle, dissolve 100 parts by mass of acrylonitrile in 400 parts by mass of dimethyl sulfoxide, then add 0.5 parts by mass of benzoyl peroxide, and keep at 70°C for 6 hours Polymerization was performed to obtain a polyacrylonitrile solution. The solution had a weight average molecular weight of 470,000. Add 100 parts by mass of polyvinyl alcohol ("Goosenol (registered trademark)" GL-05 manufactured by Nippon Synthetic Chemical Industry Co., Ltd., weight average molecular weight 10,600, SP value 32.8 (J / cm2) to this solution 3 ) 1 / 2 ), 1400 parts by mass of dimethyl sulfoxide, heated at 80° C., and stirred until all the polymers were dissolved. After the temperature of the system was returned to room temperature, 1500 parts by mass of ion-exchanged water as a poor solvent was added dropwise at a rate of 25 parts by mass / min via a liquid delivery pump to precipitate fine particles while stirring at 450 rpm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com