Manufacturing method of Foil type strain gauge

A manufacturing method and strain gage technology, applied in the direction of reducing undesired effects, etc., can solve the problems of backward production process, scattered return to zero, uneven thickness, etc., to avoid the difficulty of processing, improve the consistency of return to zero, The effect of improving bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

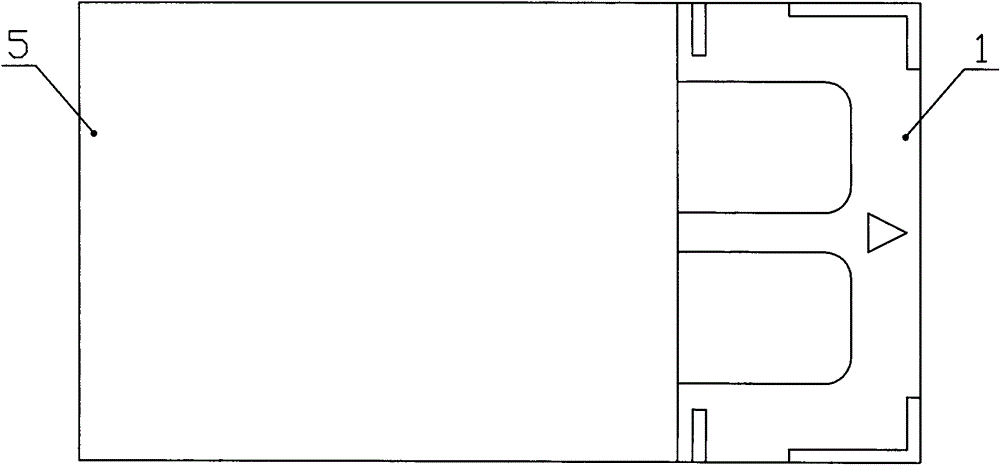

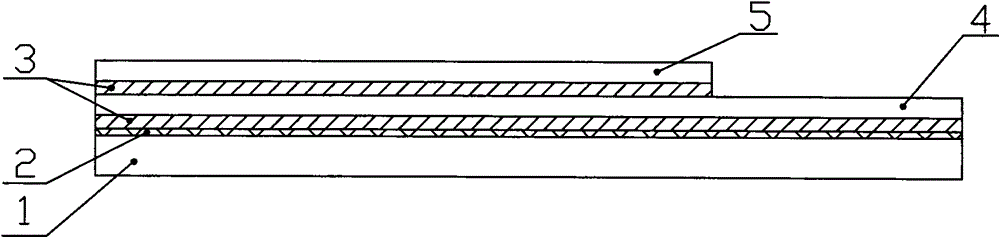

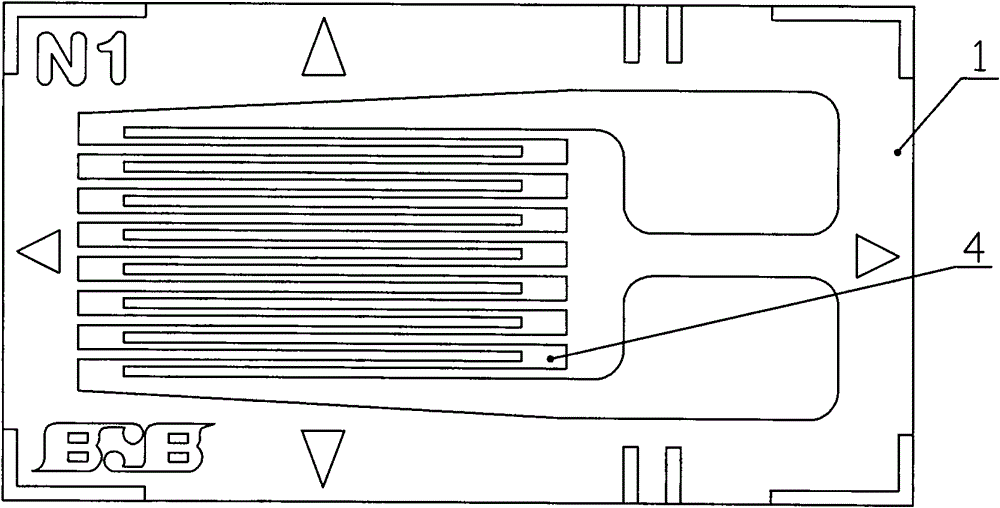

[0011] like Figure 1-3 As shown, the foil strain gauge includes a base and a sensitive grid. The base is any polymer engineering plastic film among polyimide film, polyether ether ketone film, polyphenylene sulfide film, and polyester film. One of its surfaces After treatment, a treated surface 2 capable of being strongly combined with the adhesive layer 3 is formed; the sensitive grid 4 is firmly attached to the film substrate 1 with the treated surface 2 through the adhesive layer 3 of epoxy resin or phenolic-epoxy resin; There is a sealing layer 5 on the surface of the sensitive grid 4, the material of the sealing layer 5 is the same as that of the film substrate 1, and it is firmly attached to the sensitive grid 4 through the adhesive layer 3.

[0012] The manufacture method of foil strain gauge of the present invention is:

[0013] One surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com