Synchronizer balking ring and method for manufacturing same

A manufacturing method and a synchronizer technology, applied in the field of synchronizers, can solve the problems of difficult control, complex spraying process, insignificant actual effect, etc., and achieve the effects of prolonging service life, good synchronization effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

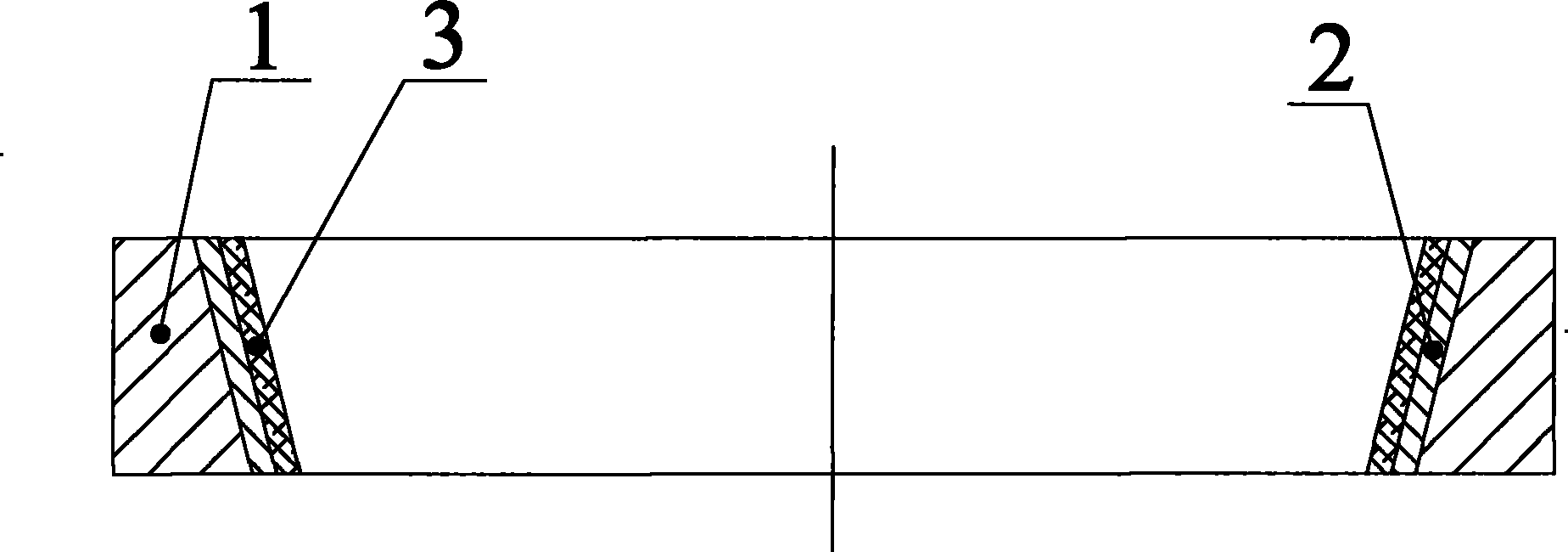

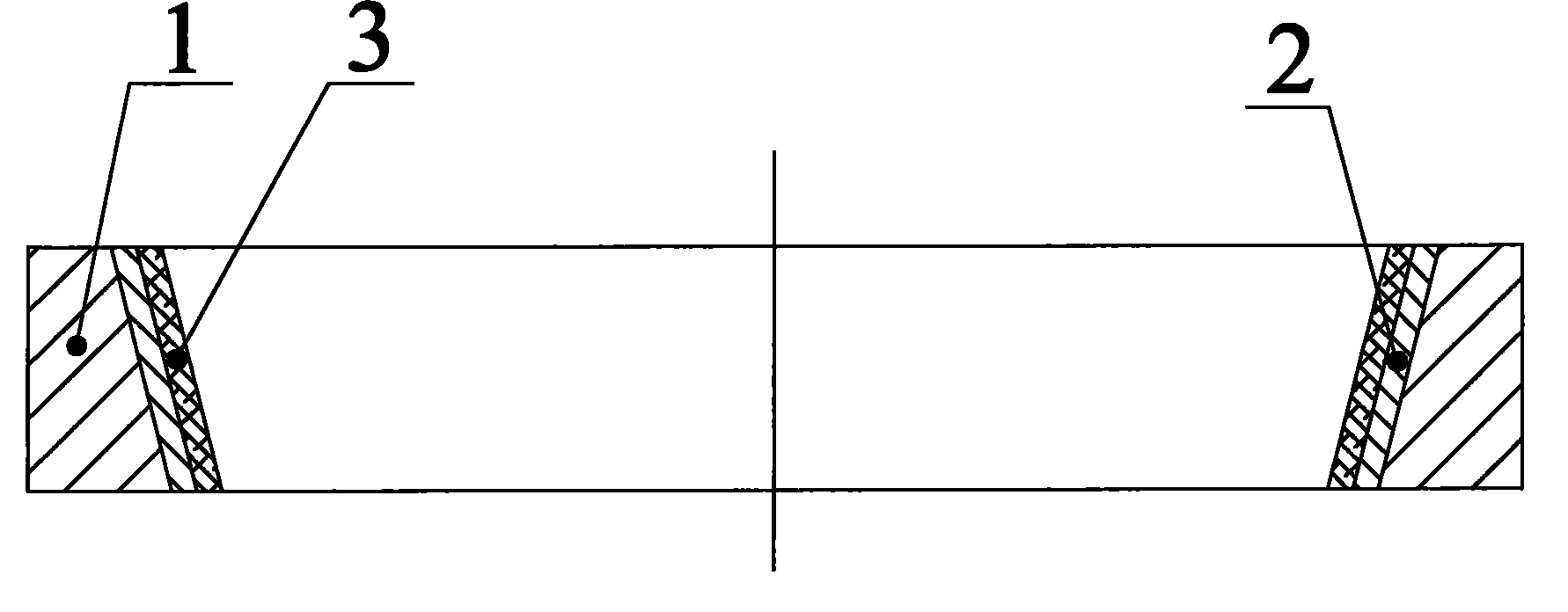

[0009] Hereinafter, the present invention will be described in detail in conjunction with the accompanying drawings.

[0010] Such as figure 1 As shown, the synchronizer cone provided by the present invention includes a cone base 1 , a metal plate layer 2 and a friction material layer 3 .

[0011] Wherein, the cone ring base 1 is made of steel. Compared with copper commonly used in the prior art, steel has the advantages of low price and good wear resistance, so the use of steel cone ring base can greatly reduce the manufacturing cost of the synchronizer cone ring and prolong its service life. Preferably, in order to further improve the hardness and wear resistance of the parts, the steel cone ring base 1 can be carburized and quenched.

[0012] The metal sheet layer 2 is joined to the inner tapered surface and / or the outer tapered surface of the cone ring base 1 . Which conical surface of the conical ring base 1 the specific metal sheet layer 2 is bonded to depends on whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com