Hollow copper telluride nanometer crystal and preparation method and application thereof

A nanocrystal and copper telluride technology, which is applied in the field of semiconductor nanocrystal synthesis, can solve problems such as unreported preparation of copper telluride nanocrystals, and achieve the effects of reducing post-processing processes, many regeneration times, and simple preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation of embodiment 1 elemental copper nanocrystal

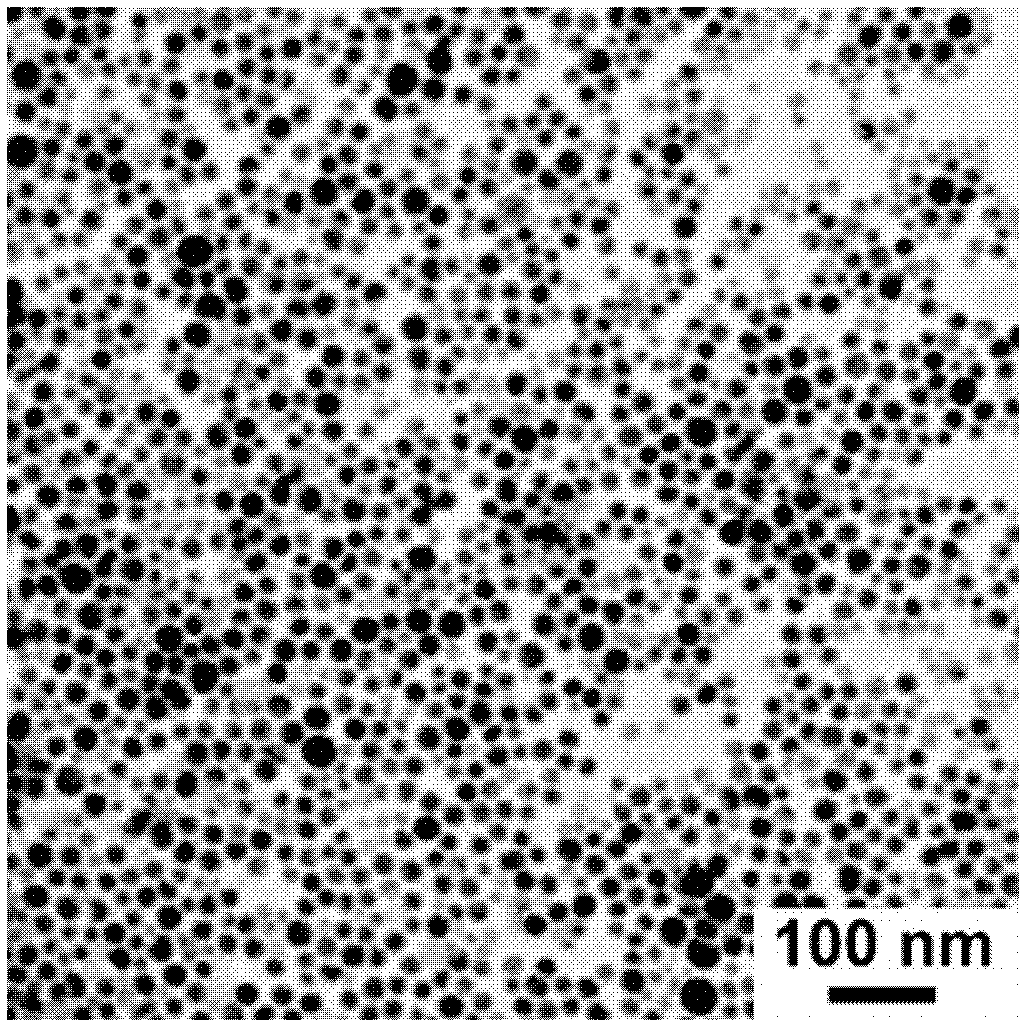

[0028] Put 0.5mmol of copper acetylacetonate, 8mL of liquid dodecylamine and 2mL of trioctylphosphine into a three-necked flask and with strong magnetic stirring, the temperature was gradually raised to 250°C under the protection of nitrogen. During this process, the color of the solution From dark green to orange-yellow, and finally a brown-red turbid solution, indicating the formation of copper nanocrystals. Such as figure 1 (a), figure 2 and image 3 Shown are X-ray electron diffraction pictures, transmission electron micrographs and high-resolution transmission electron micrographs of copper nanocrystals, respectively. It can be seen that the average diameter of the nearly spherical copper nanocrystals is about 21 nm, and the size distribution is relatively uniform.

Embodiment 2

[0029] Embodiment 2 configuration concentration is the trioctylphosphine solution of tellurium of 0.1mol / L

[0030] Mix 1 mmol of tellurium powder and 10 mL of trioctylphosphine into a 50 mL three-neck flask, raise the temperature to 200 °C under the protection of nitrogen, keep it for 4 hours, then cool down to room temperature naturally for storage for later use.

Embodiment 3

[0031] Embodiment 3 configuration concentration is the trioctylphosphine solution of tellurium of 0.3mol / L

[0032] Mix 3mmol tellurium powder and 10mL trioctylphosphine into a 50mL three-neck flask, raise the temperature to 220°C under the protection of nitrogen and keep it for 3 hours, then cool down to room temperature naturally for storage for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com