Marble cutting device

A cutting device and marble technology, applied in grinding drive devices, stone processing equipment, stone processing tools, etc., can solve problems such as low cutting efficiency, and achieve the effect of improving efficiency and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

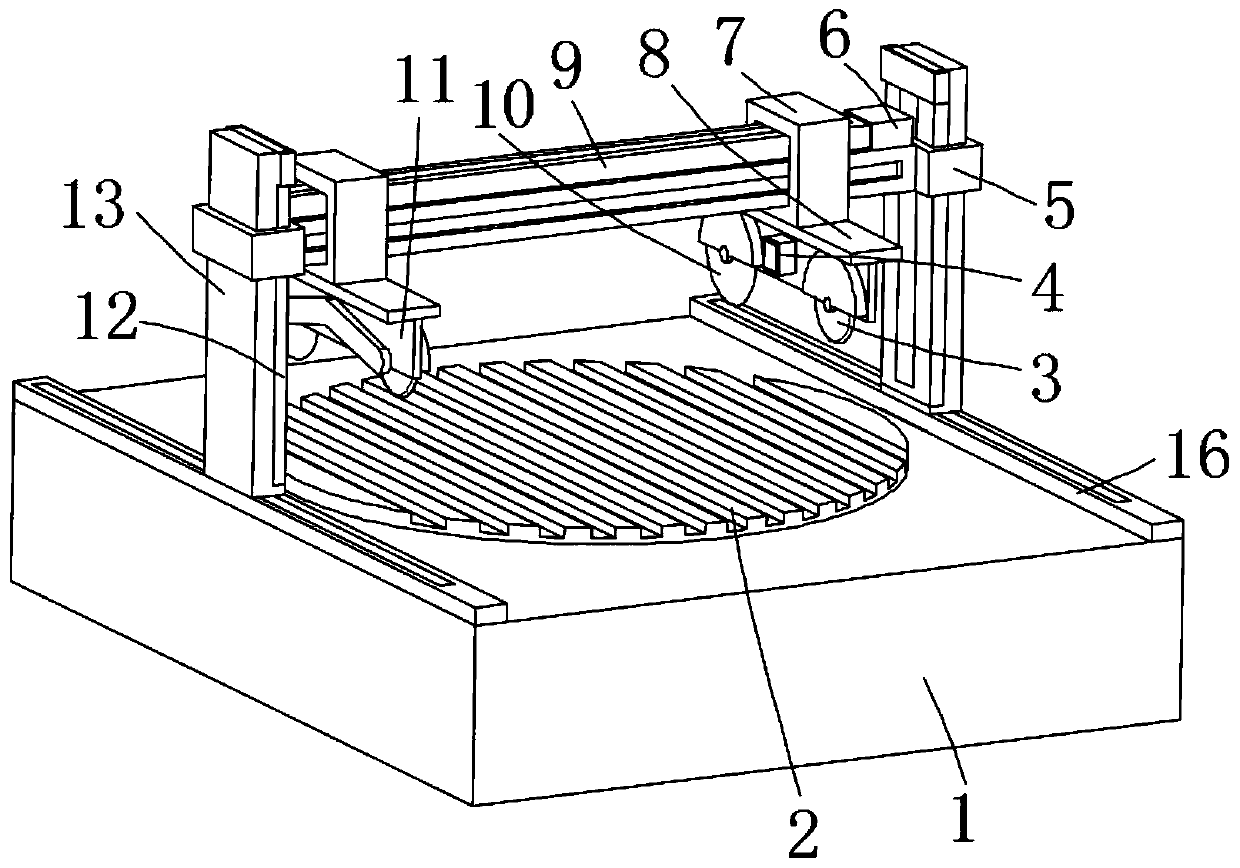

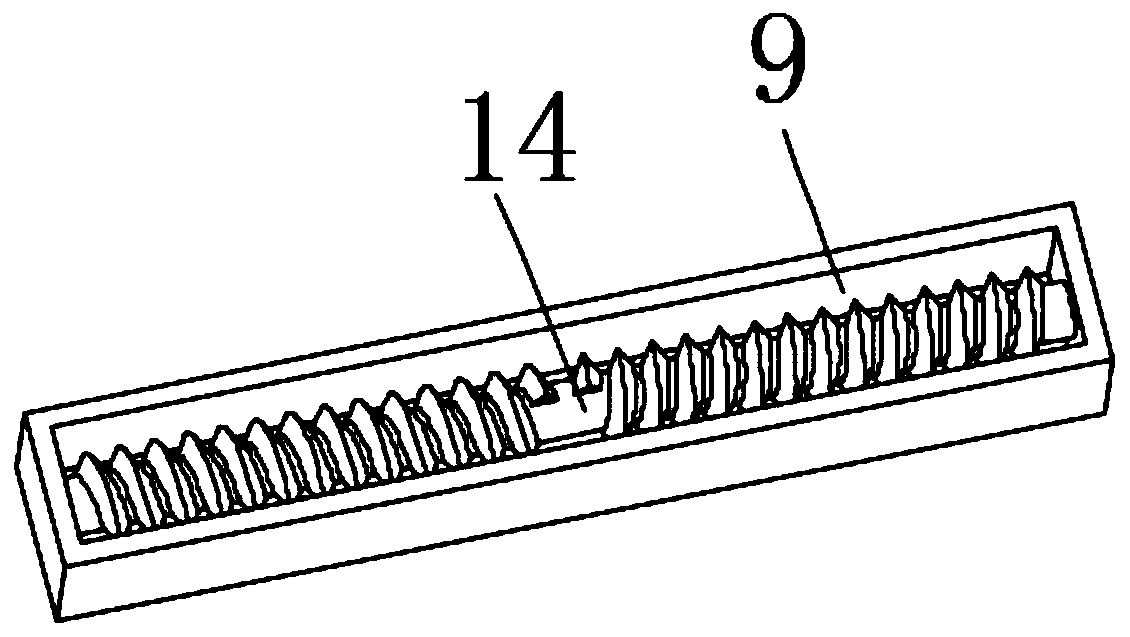

[0024] refer to figure 1 and image 3 , a marble cutting device, comprising a bottom box 1, both sides of the top outer wall of the bottom box 1 are connected with longitudinal slide rails 16 by screws, and the top outer walls of the longitudinal slide rails 16 are slidingly connected with a vertical frame 13, and the vertical frame 13 The outer walls on the opposite side are connected with vertical slide rails 12 by screws, the side outer walls of the two vertical slide rails 12 are slidingly connected with vertical sliders 5, and the outer walls on the opposite side of the vertical sliders 5 are welded with the same beam , the top outer wall of the beam is connected with a transverse guide rail shell 9 by screws, and the side outer wall of the transverse guide rail shell 9 is slidably connected with two transverse sliders 7, the bottom outer walls of the transverse sliders 7 are provided with a cutting mechanism, and the top outer wall of the bottom box 1 A loading mechanis...

Embodiment 2

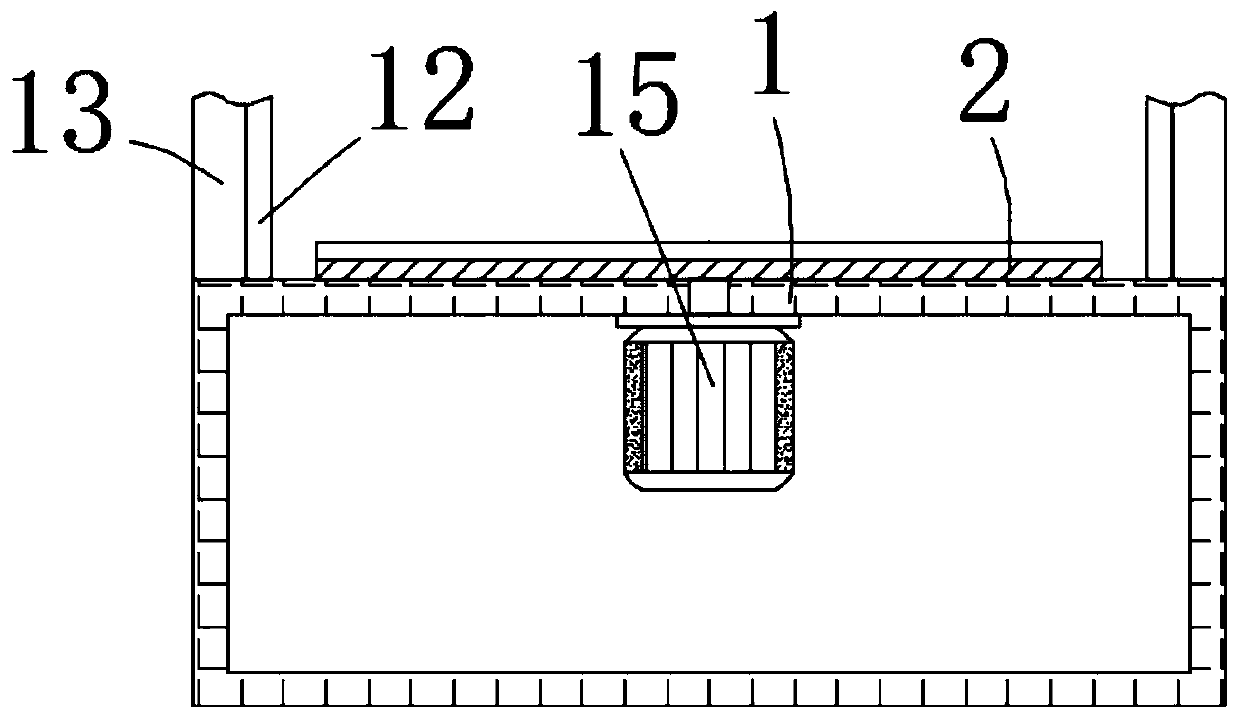

[0032] refer to figure 2 , a marble cutting device, compared with embodiment 1, in order to facilitate the cutting of marble slabs in different directions, different loading mechanisms are adopted, and the loading mechanism includes a top plate connected to the top outer wall of the bottom box 1 through bearings 2. The bottom inner wall of the bottom case 1 is connected with a rotating motor 15 by screws, and the output shaft of the rotating motor 15 is fixedly connected to the bottom outer wall of the top plate 2 .

[0033] Working principle: Compared with Example 1, when the marble slab is cut in one direction, the rotating motor 15 can drive the top plate 2 to rotate 90 degrees, and then the saw blade 10 can cut the marble slab in the other direction without manual labor Reversing, saving manpower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com