Preparation method of high-toughness polyphenyl thioether alloy

A technology of polyphenylene sulfide and manufacturing method, which is applied in the field of special polymer material manufacturing, can solve the problem of reduced tensile strength and elongation at break, reduced impact strength, and reduced impact strength and resistance of polyphenylene sulfide composite materials. Tensile strength and other issues, to achieve high thermal denaturation stability, high tensile strength, low metal corrosion rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

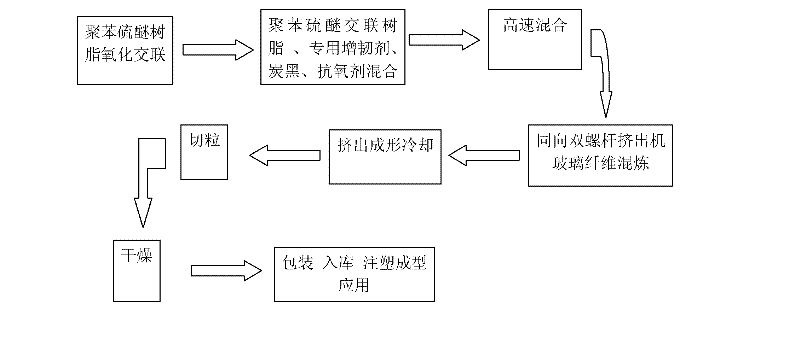

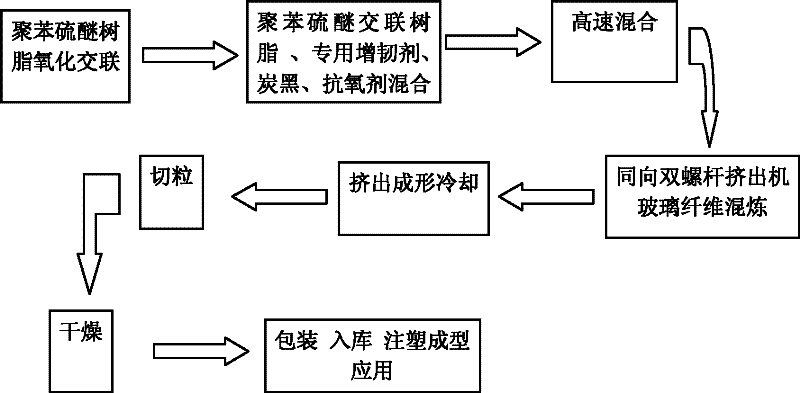

Method used

Image

Examples

Embodiment 1

[0019] Put the linear polyphenylene sulfide resin with a weight average molecular weight of 40,000, a melt flow index of 500g / 10min and a molecular weight distribution coefficient of 2.5 into the oxidative thermal crosslinker for 2.8h for oxidative thermal crosslinking.

[0020] In a high-speed mixer, add 59.8%wt polyphenylene sulfide crosslinking resin, 0.2%wt nonyl triphenyl phosphite antioxidant, 3%wt special toughening material (AX8900) with a particle size of 35um, 2%wt carbon black After stirring for 3 hours, it was mixed into a polyphenylene sulfide compound with a uniform texture, and then mixed with 35%wt of β-(3,4-epoxycyclohexyl)ethyltrimethoxysilane (A-168) surface treatment agent After treatment, the glass fiber with a single fiber diameter of 30um is input into the twin-screw extruder, mixed and extruded by the twin-screw extruder, cooled, and pelletized to form a finished alloy, which is finally packaged, stored, and used.

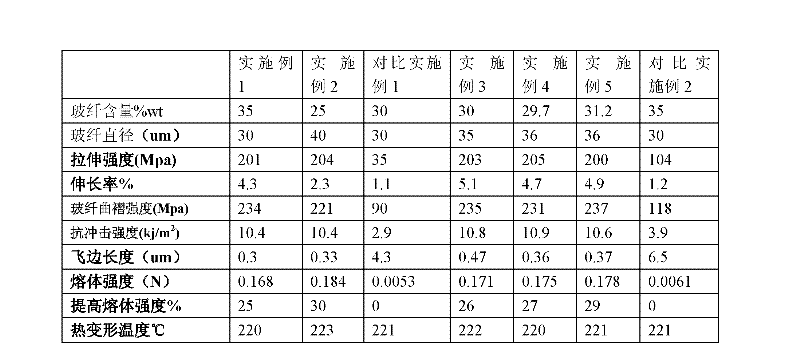

[0021] The various physical propertie...

Embodiment 2

[0023] Put the linear polyphenylene sulfide resin with a weight average molecular weight of 50,000, a melt flow index of 480g / 10min and a molecular weight distribution coefficient of 2.6 into the oxidative thermal crosslinker for 2.5h for oxidative thermal crosslinking.

[0024] In a high-speed mixer, add 65.2%wt polyphenylene sulfide cross-linking resin, 0.8%wt nonyl triphenyl phosphite antioxidant, 8%wt special toughening material with a particle size of 40um, and 1%wt carbon black and stir for 2 hours , mixed into a polyphenylene sulfide compound with a uniform texture, and then treated with 25%wt of β-(3,4-epoxycyclohexyl)ethyltrimethoxysilane (A-168) surface treatment agent Glass fibers with a fiber diameter of 40um are input into a twin-screw extruder, mixed and extruded by the twin-screw extruder, cooled, and pelletized to form a finished alloy, which is finally packaged, put into storage, and used.

[0025] The various physical properties of the polyphenylene sulfide c...

Embodiment 3

[0031] Put the linear polyphenylene sulfide resin with a weight average molecular weight of 43,000, a melt flow index of 486g / 10min and a molecular weight distribution coefficient of 2.55 into an oxidative heat crosslinker for 2.6 hours of oxidative heat crosslinking.

[0032] In a high-speed mixer, add 63%wt polyphenylene sulfide crosslinking resin, 0.5%wt nonyl triphenyl phosphite antioxidant, 5%wt special toughening material (AX8900) with a particle size of 35um, and 1.5%wt carbon black After stirring for 3 hours, it was mixed into a polyphenylene sulfide compound with a uniform texture, and then mixed with 30%wt of β-(3,4-epoxycyclohexyl)ethyltrimethoxysilane (A-168) surface treatment agent After treatment, the glass fiber with a single fiber diameter of 30um is input into the twin-screw extruder, mixed and extruded by the twin-screw extruder, cooled, and pelletized to form a finished alloy, which is finally packaged, stored, and used.

[0033] The various physical propert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt flow index | aaaaa | aaaaa |

| Melt flow index | aaaaa | aaaaa |

| Melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com