Method for detecting staphylococcus aureus

A staphylococcus, golden yellow technology, applied in the field of microbial detection, can solve the problems of high sensitivity requirements, long detection time, inability to distinguish the activity of pathogenic bacteria, etc., and achieve the effect of good stability and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Preparation of Immunized Superparamagnetic Nanomagnetic Beads and Enrichment of Bacteria

[0047] 1. Magnetic core Fe 3 o 4 Synthesis and silicon-coated

[0048] Separately prepare FeSO with double distilled water 4 ·7H 2 O, FeCl 3 ·6H 2 O, 2.5mol / L NaOH three kinds of solutions, the FeSO 4 ·7H 2 O, FeCl 3 ·6H 2 O The two solutions are mixed so that the concentration of ferrous ions in the mixed solution is 0.15mol / L, and the concentration of ferric ions is 0.25mol / L, and the NaOH solution configured above is slowly added dropwise under vigorous stirring into the mixed iron salt solution, age the obtained precipitate at 60°C for 2 hours, wash the precipitate with double distilled water for 3 to 5 times, filter and dry at 60°C for 24 hours, and grind it in an agate mortar to obtain the product. Dry at 60°C and store at room temperature for later use.

[0049] Due to the magnetic core Fe 3 o 4 The dispersibility is poor, the particle size is uneven, and it is...

Embodiment 2

[0054] Preparation of Colloidal Gold Immunochromatographic Test Paper for Staphylococcus aureus

[0055] 1. Preparation of colloidal gold-labeled Staphylococcus aureus monoclonal antibody complex

[0056] Label the Staphylococcus aureus monoclonal antibody on the prepared colloidal gold surface with an average particle size of 10-80nm, then wash twice with 0.002M boric acid buffer solution, and concentrate to 1 / 50-1 / 2. Generally 1 / 25, store at 4°C for later use.

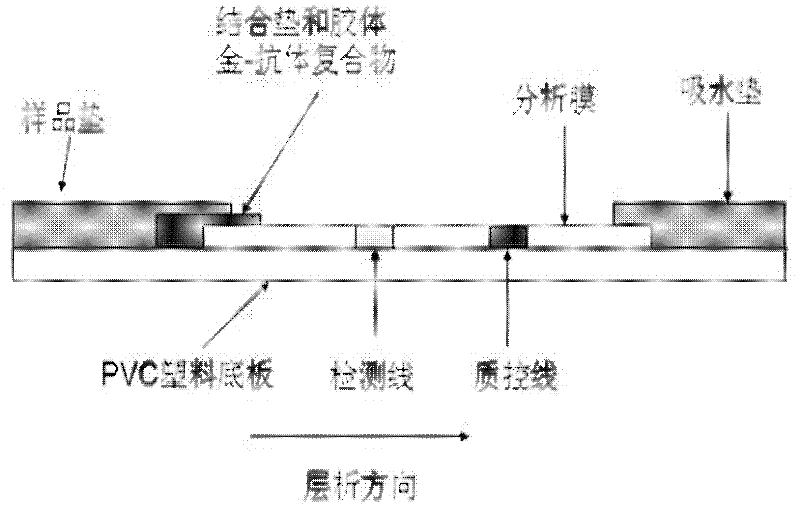

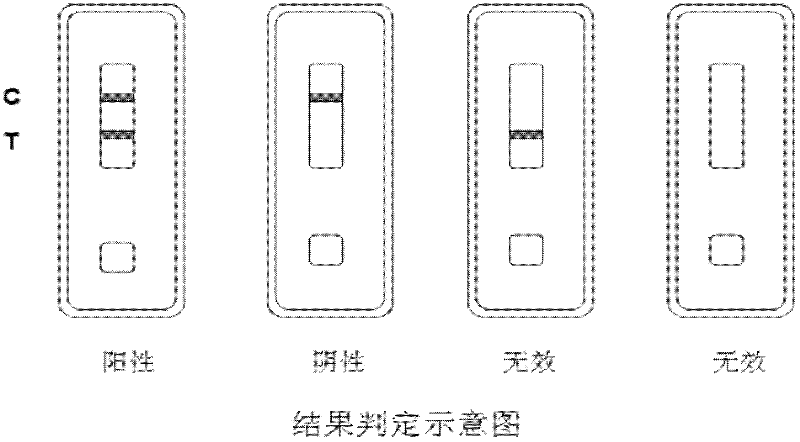

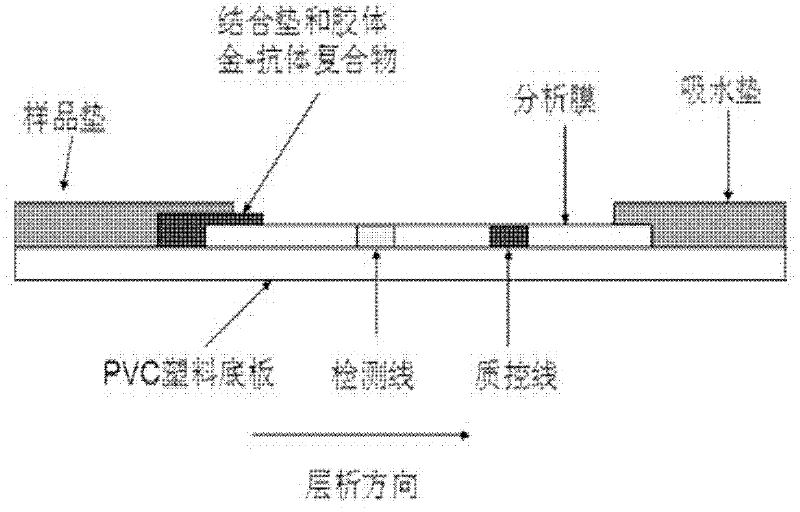

[0057] 2. Preparation of colloidal gold immunochromatography test paper

[0058]2.1 Preparation of sample pad: In this embodiment, glass cellulose film is selected as the sample pad material, and the glass cellulose film is put into the sample pad treatment solution (0.01M PBS (PH=7.4), containing 1% BSA, 0.1% Trion Soak in X-100) and dry at 30-45°C, usually 37°C.

[0059] 2.2 Preparation of conjugation pad: In this example, glass cellulose membrane was selected as the sample pad material, and the colloidal gold-...

Embodiment 3

[0064] 1, carry out specificity test to test paper of the present invention by detecting 90 parts of food samples

[0065] 50 food samples containing Staphylococcus aureus, 10 food samples containing Escherichia coli O157:H7, 10 food samples containing Listeria monocytogenes, 10 food samples of Enterobacter sakazakii, and 10 blank cultures As the sample to be tested, 5ml was taken out and mixed with 50μl superparamagnetic nanoparticles coated with Staphylococcus aureus specific antibody after ultrasonication for 10min respectively to form a complex of antibody-magnetic particle-Staphylococcus aureus; Under the action of attraction, the complex is collected; the complex is inoculated into 7.5% sodium chloride broth culture medium for 6-12 hours, and the antibody-magnetic particle-Staphylococcus aureus is magnetically separated under a 3000Gs magnetic field The complex, the bacterial solution after magnetic separation was centrifuged at 15000r / min for 20min, then dissolved in 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com