Method for improving toughness of middle chromium ferritic stainless steel medium plate

A kind of stainless steel, element body technology, applied in the field of metallurgy, to achieve the effect of structure refinement and toughness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The chemical composition of the ferritic stainless steel used is: Cr 17%, C 0.005%, N 0.006%, Nb 0.04%, Ti 0.1%, V 0.12%, Mn 0.28%, Si 0.19%, and the balance is Fe and Unavoidable impurities.

[0030] The above-mentioned ferritic stainless steel is smelted and poured to make a slab, heated to 1200°C, kept for 1 hour, air-cooled to 1100°C, then rough rolled and finish rolled, the total reduction is 79%, and the final rolling temperature is 850°C , air-cooled to room temperature to obtain a rolled plate.

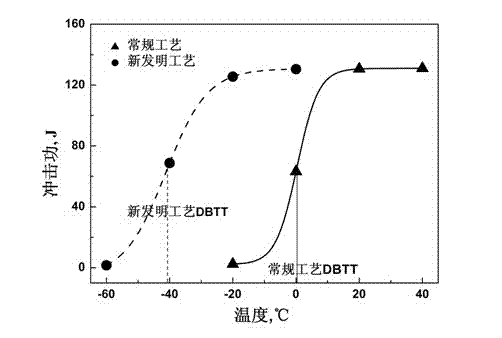

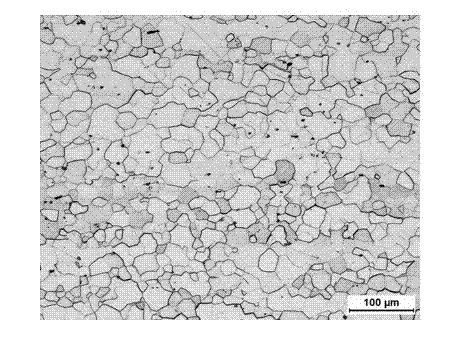

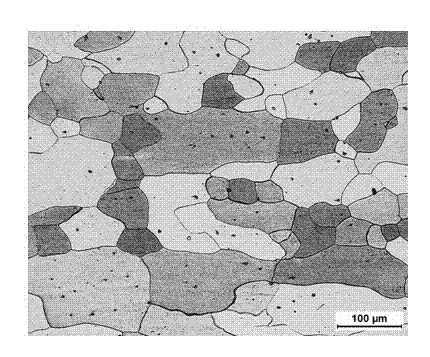

[0031] The rolled sheet obtained by finish rolling was reheated to 260° C., and subjected to multi-pass rolling deformation at 260° C. with a cumulative reduction of 66.5%, to obtain a rolled sheet of 6 mm. The rolled plate deformed by multi-pass rolling was kept at 850°C for 5 min to fully recrystallize to obtain the finished plate with fine-grained structure. The corresponding structure is equiaxed ferrite structure with an average grain size of 27.2 μm, such as f...

Embodiment 2

[0035] The chemical composition of the ferritic stainless steel used is: Cr 17%, C 0.006%, N 0.006%, Nb 0.04%, Ti 0.2%, Mn 0.5%, Si 0.01%, and the balance is Fe and unavoidable impurities.

[0036] The above-mentioned ferritic stainless steel is smelted and poured to make a slab, heated to 1250°C, kept for 1 hour, air-cooled to 1100°C, then rough rolled and finish rolled, the total reduction is 70%, and the final rolling temperature is 950°C , air-cooled to room temperature to obtain a rolled plate.

[0037] The rolled sheet slab obtained by finish rolling was reheated to 600°C, and subjected to multi-pass rolling deformation at 600°C with a cumulative reduction of 80%, to obtain a rolled sheet of 6mm. The rolled plate deformed by multi-pass rolling was kept at 850°C for 5 min to fully recrystallize to obtain the finished plate with fine-grained structure.

[0038]The impact samples with dimensions of 5mm×10mm×55mm were obtained through sawing machine and grinding machine. C...

Embodiment 3

[0040] The chemical composition of the ferritic stainless steel used is: Cr 22%, C 0.008%, N 0.007%, Nb 0.3%, V 0.12%, Mn 0.1%, Si 0.6%, and the balance is Fe and unavoidable impurities.

[0041] The above-mentioned ferritic stainless steel is smelted and poured to make a slab, heated to 1100°C, kept for 2 hours, air-cooled to 1100°C, then rough rolled and finish rolled, the total reduction is 90%, and the final rolling temperature is 850°C , air-cooled to room temperature to obtain a rolled plate.

[0042] The rolled sheet obtained by finish rolling was reheated to 400° C., and subjected to multi-pass rolling deformation with a cumulative reduction of 40% at 400° C. to obtain a rolled sheet of 11 mm. The rolled plate deformed by multi-pass rolling was kept at 900°C for 10 min to make it fully recrystallized, and then the finished plate with fine-grained structure was obtained.

[0043] The impact samples with dimensions of 10mm×10mm×55mm were obtained through sawing machine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Ductile-brittle transition temperature | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com