Technique for recycling aluminum hydroxide from waste liquid for acid washing and alkaline washing aluminum-based material

A technology of aluminum hydroxide and pickling waste liquid, applied in aluminate/alumina/aluminum hydroxide purification, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problem of frequent filter cloth replacement, reducing agent Large amount of use, pollution and other problems, to achieve significant social and economic benefits, no secondary pollution, scientific process route effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

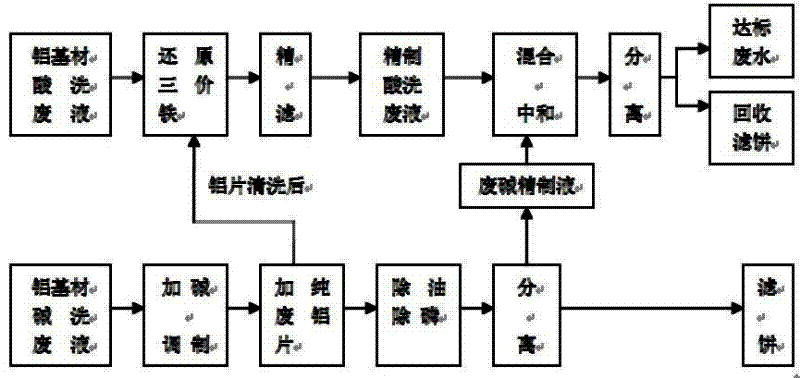

[0016] In conjunction with the accompanying drawings and embodiments, the specific process steps of the process of the present invention are further described.

[0017] The present invention reclaims the technology of aluminum hydroxide from aluminum substrate pickling alkaline washing waste liquid, see figure 1 , take the following process steps: pretreatment of aluminum substrate pickling waste liquid and alkali washing waste liquid respectively→mixing→neutralization→separation, discharge the waste water up to the standard, send the filter cake of the waste alkali pretreatment to the cement plant as raw material, aluminum hydroxide Filter cake recycling.

[0018] In the above steps, the alkaline cleaning waste liquid is pretreated, and liquid caustic soda is first added to the alkaline cleaning waste liquid to make the total alkalinity of the waste liquid reach 0.5~5mol / L, and the aluminum base material processing The waste aluminum material whose surface coating has been r...

Embodiment 2

[0020] The process for recovering aluminum hydroxide from aluminum substrate pickling and alkaline cleaning waste liquid of the present invention comprises the following steps: (1) pretreating the aluminum substrate pickling waste liquid and alkaline cleaning waste liquid respectively; (2) The pretreated pickling waste liquid and alkaline washing waste liquid are mixed, neutralized and separated, the waste water is discharged up to the standard, and the filter cake is aluminum hydroxide, which is directly used as an industrial raw material.

[0021] In the above process, the alkaline cleaning waste liquid is pretreated, and liquid caustic soda is first added to the alkaline cleaning waste liquid to make the total alkalinity of the waste liquid reach 0.5mol / L, and the aluminum base material processing is added to it. The waste aluminum material whose surface coating has been removed is soaked and reacted until a large amount of gas is generated, and then quickly taken out and wa...

Embodiment 3

[0025] The process for recovering aluminum hydroxide from aluminum substrate pickling and alkaline cleaning waste liquid of the present invention comprises the following steps: (1) pretreating the aluminum substrate pickling waste liquid and alkaline cleaning waste liquid respectively; (2) The pretreated pickling waste liquid and alkaline washing waste liquid are mixed, neutralized and separated, the waste water is discharged up to the standard, and the filter cake is aluminum hydroxide, which is directly used as an industrial raw material.

[0026] In the above process, the alkaline cleaning waste liquid is pretreated, and liquid caustic soda is first added to the alkaline cleaning waste liquid to make the total alkalinity of the waste liquid reach 5mol / L, and the aluminum substrate processing is added to it. Remove the scrap aluminum material with surface coating, soak it until a large amount of gas is generated, take it out quickly and wash it with water; add soluble calcium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com