Online repair method for local damage of aluminum electrolytic cell cathode

An aluminum electrolytic cell and electrolytic cell technology, which is applied in the field of repairing damaged parts of the cathode, can solve problems such as affecting production operation, reducing the serial slotting rate and production capacity, and exacerbating the problem, and achieves the effect of inhibiting continued damage and convenient and quick material acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The specific repair method is as follows:

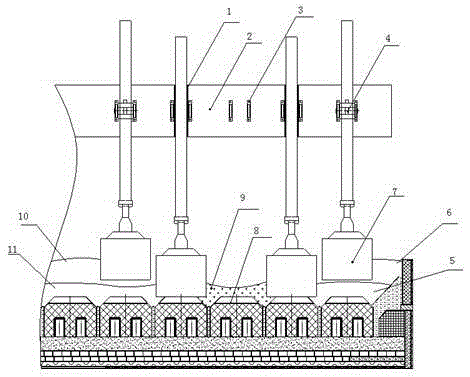

[0026] 1) Propose the damaged part of the cathode and its adjacent anode, remove the shell block in the electrolyte of the lifted part, install a new pole in the position adjacent to the damaged part (no pole is installed at the damaged part), and connect the guide rod and the anode with an insulating plate After the bus bar of the beam is disconnected, it sinks to the bottom of the tank, making the anode of this piece non-conductive (such as figure 1 shown);

[0027] 2) Quickly put repairing material 1 in the damaged part of the cathode. The repairing material 1 is made by mixing the surface shell block and alumina in a mass ratio of 1:3. The surface shell block is the surface covering material of the electrolytic residual carbon block after cooling and crushing The repair material 1 makes the electrolyte in the area solidify in a short period of time. During the solidification process, the repair material 1 is continuously ...

Embodiment 2

[0037] The difference from Example 1 is steps 2) and 3).

[0038] 2) Quickly put repairing material 1 into the damaged part of the cathode. The repairing material 1 is made by mixing the shell block and alumina in a mass ratio of 0.8:2.5. The shell block is the surface covering material of the electrolytic residual carbon block after cooling and crushing The repair material 1 makes the electrolyte in the area solidify in a short period of time. During the solidification process, the repair material 1 is continuously put in, and the repair material 1 is pressurized by the head of the crown block to strengthen its solidification until the electrolyte in the damaged part Completely solidified, the aluminum liquid is completely discharged;

[0039] 3) When the temperature of the mixed material 1 at the damaged part drops below 400°C, remove the repairing material 1 at the damaged part of the cathode, and use the repairing material 2 prepared in advance, that is, fine magnesia, ant...

Embodiment 3

[0041] The difference from Example 1 is steps 2) and 3).

[0042] 2) Quickly put repairing material 1 in the damaged part of the cathode. The repairing material 1 is made by mixing the surface shell block and alumina in a mass ratio of 1.2:3.5. The surface shell block is the surface covering material of the electrolytic residual carbon block after cooling and crushing The repair material 1 makes the electrolyte in the area solidify in a short period of time. During the solidification process, the repair material 1 is continuously put in, and the repair material 1 is pressurized by the head of the crown block to strengthen its solidification until the electrolyte in the damaged part Completely solidified, the aluminum liquid is completely discharged;

[0043] 3) When the temperature of the mixed material 1 at the damaged part drops below 400°C, remove the repairing material 1 at the damaged part of the cathode, and use the repairing material 2 prepared in advance, that is, fine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com