Laminated glass and preparation process thereof

A technology of laminating glass and glass, applied in glass manufacturing equipment, manufacturing tools, glass tempering and other directions, can solve the problems of less usage and lower transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Including the upper layer of ultra-clear coated glass layer, film layer and lower layer of ultra-clear coated glass arranged in sequence from top to bottom; the thickness of the film layer is 0.76mm or 1.14mm or 1.52mm or 1.9mm; the upper layer of ultra-clear coated glass layer Or the thickness of the lower layer of ultra-clear coated glass is 0.6-6 mm, and the film in the film layer is an SGP film. The upper layer of ultra-white coated glass and the lower layer of ultra-white coated glass are tempered glass with a thickness of 0.6-0.9mm, and the thickness of the film layer is 1.9mm.

[0046] The process for preparing laminated glass includes the following process steps:

[0047] S1: Cut the original glass sheet with a thickness of 6mm into the set size and use a glass edger to edge it;

[0048] S2: Clean the glass treated in step S1 and dry it, then place the glass in a drying room until the glass reaches room temperature;

[0049] S3: Put the glass treated in step S2 ...

Embodiment 2

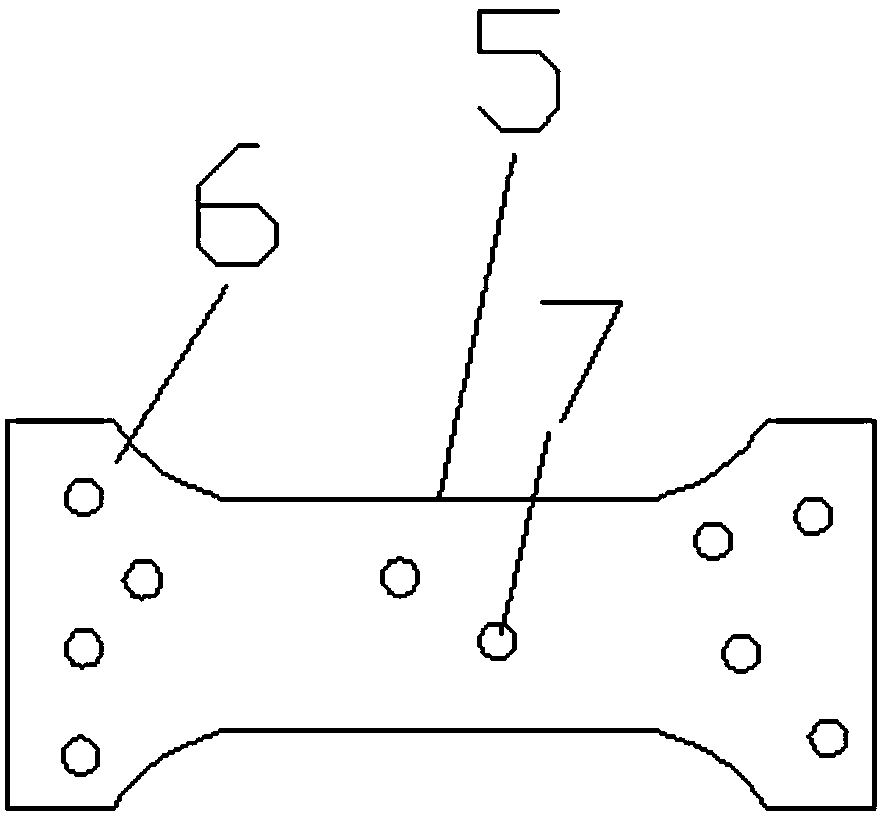

[0055] The difference from Embodiment 1 is that, as figure 1 As shown, the laminated glass includes an upper transparent material layer, a film layer and a lower transparent material layer arranged sequentially from top to bottom; the thickness of the film layer is 0.76mm or 1.14mm or 1.52mm or 1.9mm; the upper layer is transparent The thickness of the material layer or the lower transparent material layer is 0.6-6mm, the film in the film layer is polycarbonate film, and the material used in the upper transparent material layer or the lower transparent material layer is anti-reflection glass or ultra-thin float glass or Semi-tempered glass or plexiglass. The material used for the upper transparent material layer 1 or the lower transparent material layer 2 is anti-reflection glass or ultra-thin float glass or semi-tempered glass, and glass fibers 3 crossed vertically and vertically are arranged in the upper transparent material layer 1 or the lower transparent material layer 2 ...

Embodiment 3

[0057] The difference from Example 1 is that the process for preparing laminated glass includes the following process steps:

[0058] S1: Laminated glass is made from molten glass raw materials and polycarbonate film using a float glass preparation process; the glass raw materials include SiO2, Al2O3, K2O, Na2O, CaO and MgO, SiO2 is 72.8 to 73.9 parts by weight, and Al2O3 is 0.7-0.9 parts by weight, 0.1-0.3 parts by weight of K2O, 13-14 parts by weight of Na2O, 7.7-9.8 parts by weight of CaO, and 3.3-3.8 parts by weight of MgO. The molten liquid is melted at high temperature in the French glass melting furnace. The molten liquid flows into the working pool after being clarified and homogenized. The molten liquid enters the forming tin tank from the launder in the working pool to form a strip-shaped continuous glass plate. Cut into finished products; the melting temperature in the float glass melting furnace is 1220-1295°C, the clarification and homogenization temperature is 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com