Ethylene-a-olefin copolymer

An olefin copolymer and copolymer technology, applied in the field of ethylene-α-olefin copolymer, can solve the unsatisfactory problems of ethylene-based polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

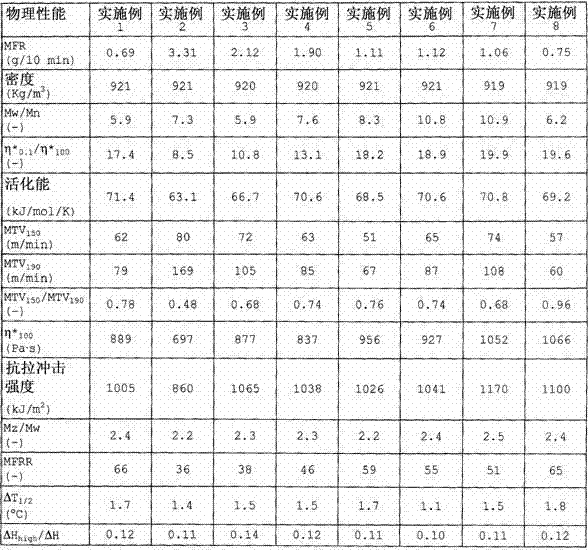

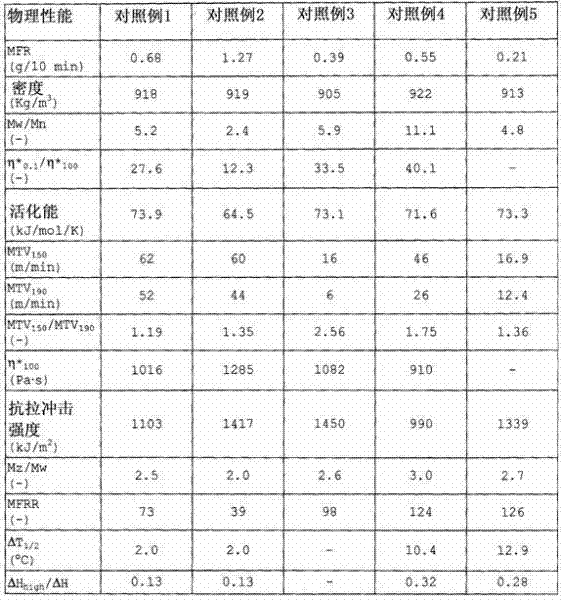

Examples

Embodiment 1)

[0095] (1) Preparation of co-catalyst carrier

[0096] A 200-mL separable flask with a tank diameter of 58 mm and equipped with two baffle fingers and a Pfaudler-type impeller with a diameter of 35 mm was purged with nitrogen, and 60 mL of toluene as a solvent and the 10.6 g of silica (Sylopol 948 produced by DavisonCo. Ltd.; average particle diameter: 55 μm; pore volume: 1.67 mL / g; specific surface area: 325 m 2 / g) into the flask and stirred. Subsequently, 21.1 mL of a hexane solution of diethylzinc having a diethylzinc concentration of 2 mmol / mL was charged into the flask and stirred. Thereafter, the flask was cooled to 5°C, and the temperature inside the flask was kept at 5°C, and 19.3mL of 1,1-bis(trifluoromethyl)-2,2,2-trifluoroethanol was added dropwise over 30 minutes with a concentration of 2.22mmol / mL of 1,1-bis(trifluoromethyl)-2,2,2-trifluoroethanol in toluene. After the dropwise addition was complete, stirring was continued at 5°C for 1 hour and at 40°C for 1 ...

Embodiment 2)

[0100] A 5 liter autoclave equipped with a stirrer was dried under reduced pressure, flushed with argon, and evacuated. Then, hydrogen gas was added thereto so that the partial pressure could become 0.033 MPa, and then 270 mL of 1-hexene and 1020 g of butane were added. When the temperature in the system rose to 70°C, ethylene was added therein so that the partial pressure could become 1.6 MPa, and the system was stable. Gas chromatographic analysis found that the gas composition in the system included hydrogen at a concentration of 1.86 mol%. 2.0 mL of a heptane solution of triisobutylaluminum having a triisobutylaluminum concentration of 1.0 mmol / mL was added to the system. Subsequently, 1.0 mL of a toluene solution of racemic ethylene bis(1-indenyl) zirconium diphenolate with a concentration of 2 μmol / mL was added, followed by 6.4 mg of the cocatalyst carrier (A1) obtained in Example 1 (1) above. The polymerization reaction was carried out at 70°C for 180 minutes while c...

Embodiment 3)

[0102] A 5 liter autoclave equipped with a stirrer was dried under reduced pressure, flushed with argon, and evacuated. Then, hydrogen gas was added thereto so that the partial pressure could become 0.021 MPa, and then 280 mL of 1-hexene and 1012 g of butane were added. When the temperature in the system rose to 70°C, ethylene was added therein so that the partial pressure could become 1.6 MPa, and the system was stable. Gas chromatographic analysis found that the gas composition in the system included hydrogen at a concentration of 1.08 mol%. 4.0 mL of a heptane solution of triisobutylaluminum having a triisobutylaluminum concentration of 0.5 mmol / mL was added to the system. Subsequently, 1.0 mL of a toluene solution of racemic ethylene bis (1-indenyl) zirconium dichloride at a concentration of 1 μmol / mL was added, and then 4.1 mg of the cocatalyst carrier (A1) obtained in the above-mentioned Example 1(1) was added. The polymerization reaction was carried out at 70°C for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com