Thixotrope for high-power wind turbine blade and preparation method thereof

A technology of wind turbine blades and thixotropic glue, applied in the direction of adhesive, epoxy resin glue, adhesive type, etc., can solve the problems of short pot life, high water absorption, poor aging resistance, etc., to improve water resistance and surface energy. High, improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0036] (1) Preparation of component A of thixotrope

[0037] 20g of bisphenol A type epoxy resin E51, 40g of bisphenol A type epoxy resin E44, 5g of hydroxyl-terminated polyurethane toughening agent for special polyurethane, 5g of ethylene glycol diglycidyl ether, 0.1g of silane coupling agent KH- 560, 15g of glass fiber with a length of 0.1mm, 5g of activated white carbon black, and 0.1g of glycerin are poured into a kneader with a heating device, and mixed for 30 minutes under normal pressure at 60°C. Grind and disperse with a three-roll mill to make component A of the thixotrope.

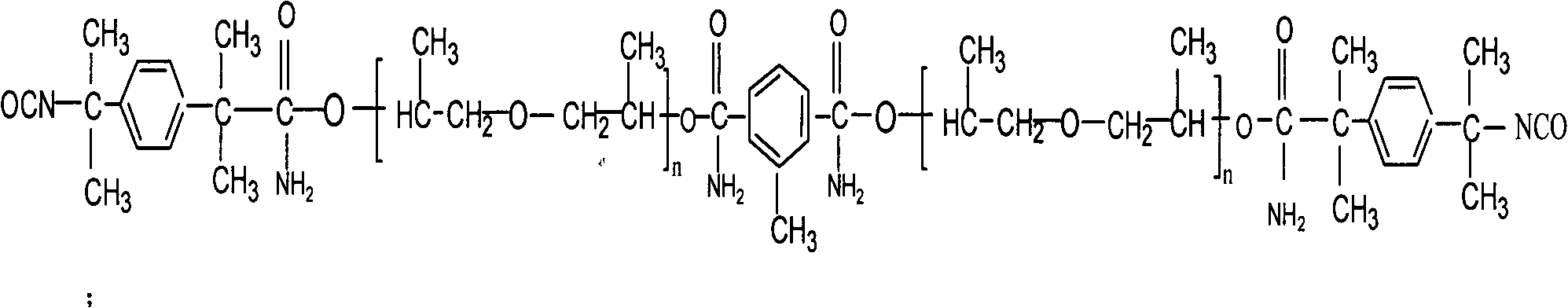

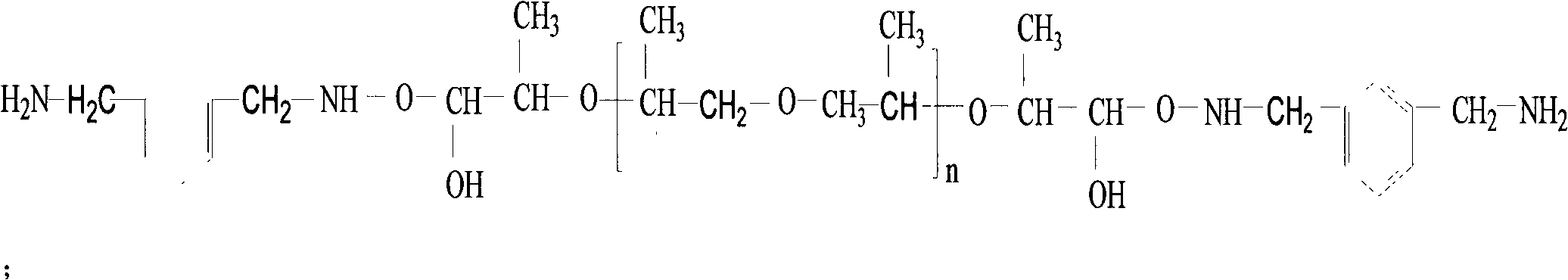

[0038] The preparation method of the hydroxyl-terminated polyurethane toughening agent of the special polyurethane is as follows: add 100 g of polyether diol with an average molecular weight of 1200 and 7.2 g of toluene diisocyanate (TDI) in a flask, and stir under normal pressure and 60 ° C. , reacted for 30 minutes, then raised the temperature to 80°C and stirred, and reacted for 3 hours to ma...

example 2

[0045] (1) Preparation of component A of thixotrope

[0046] 35g of bisphenol A type epoxy resin E44, 35g of bisphenol A type epoxy resin E51, 8g of hydroxyl-terminated polyurethane toughening agent for special polyurethane, 8g of ethylene glycol diglycidyl ether, 0.3g of silane coupling agent KH- 560, 20g of glass fiber with a length of 0.5mm, 8g of activated white carbon black, and 0.2g of glycerin, poured into a kneader with a heating device, and mixed for 30 minutes under normal pressure at 60°C. Grind and disperse with a three-roll mill to make component A of the thixotrope.

[0047] The preparation method of the hydroxyl-terminated polyurethane toughening agent of the special polyurethane is as follows: add 100 g of polyether diol with an average molecular weight of 1200 Daltons and 7.2 g of toluene diisocyanate (TDI) in a flask, under normal pressure and 60 ° C. Under stirring, react for 30 minutes, then raise the temperature to 80° C. and stir, react for 4 hours, so t...

example 3

[0054] (1) Preparation of component A of thixotrope

[0055] 10g of bisphenol A type epoxy resin E44, 70g of bisphenol A type epoxy resin E51, 10g of hydroxyl-terminated polyurethane toughening agent for special polyurethane, 10g of ethylene glycol diglycidyl ether, 0.5g of silane coupling agent KH- 560, 25g of glass fibers with a length of 0.8mm, 10g of activated white carbon black, and 0.5g of glycerin are poured into a kneader with a heating device, and mixed for 30 minutes under normal pressure at 60°C. Grind and disperse with a three-roll mill to make component A of the thixotrope.

[0056] The preparation method of the hydroxyl-terminated polyurethane toughening agent of special polyurethane is as follows: add 100 g of polyether diol with an average molecular weight of 1200 and 7.2 g of toluene diisocyanate (TDI) in a flask, stir under normal pressure and 60 ° C, React for 30 minutes, then raise the temperature to 80° C. and stir, and react for 5 hours to make the molec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com