Processing method for double-mask silicon on insulator (SOI) micro electro mechanical system (MEMS)

A processing method and double-mask technology are applied in metal material coating technology, technology for producing decorative surface effects, decorative arts, etc., which can solve the problems of reducing the Footing effect and increasing the parasitic capacitance of the all-silicon structure, and achieve reduction Small Footing effect, uniform thickness, and reduced parasitic capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

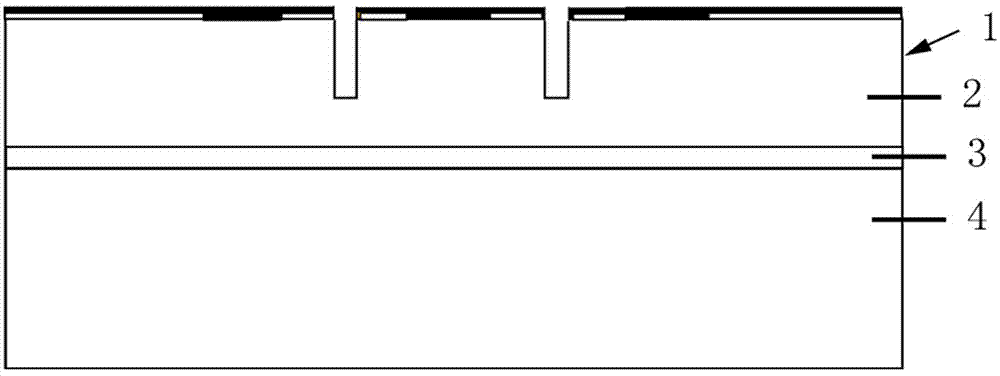

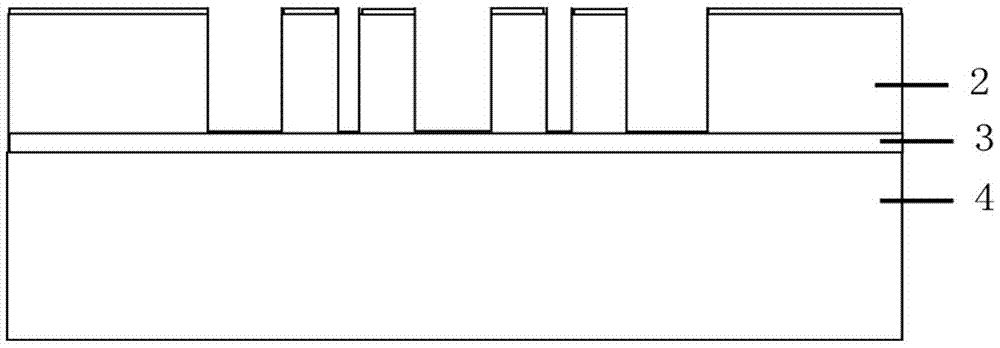

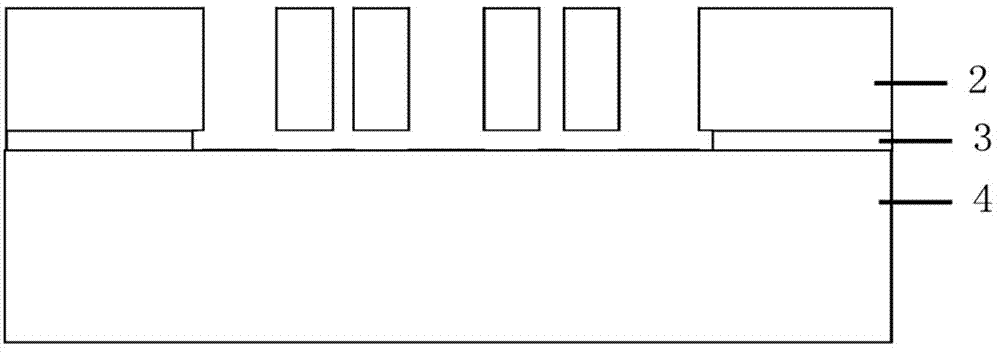

[0015] Figure 1-Figure 4 It is a schematic diagram of the process flow of the double-mask SOI MEMS processing method. This processing method uses SOI wafer 1 to manufacture MEMS devices, and adopts double mask technology, which can effectively reduce the Footing effect at the bottom of the silicon structure layer 2 and reduce the gap between the mass block and other structures on the silicon structure layer 2 and the silicon substrate layer 4. the parasitic capacitance between them.

[0016] exist figure 1 Among them, the SOI wafer 1 includes a layer of silicon dioxide (SiO2) layer 3 located between the silicon structure layer 2 and the silicon substrate layer 4. The silicon structure layer 2 is doped with concentrated boron, and the doping concentration is greater than . The processing method is realized through the following process steps:

[0017] (1) Sputter a layer of aluminum on the front of the silicon wafer, photolithography, etch the aluminum, and define a comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com