Low-temperature plasma catalyst, and preparation method and application thereof

A low-temperature plasma and catalyst technology, applied in the field of catalytic chemistry, can solve the problems of ineffective photocatalysis, increased energy consumption, weak ultraviolet light, etc., and achieve the effect of increasing ultraviolet light intensity, increasing electric field intensity, and simple use process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

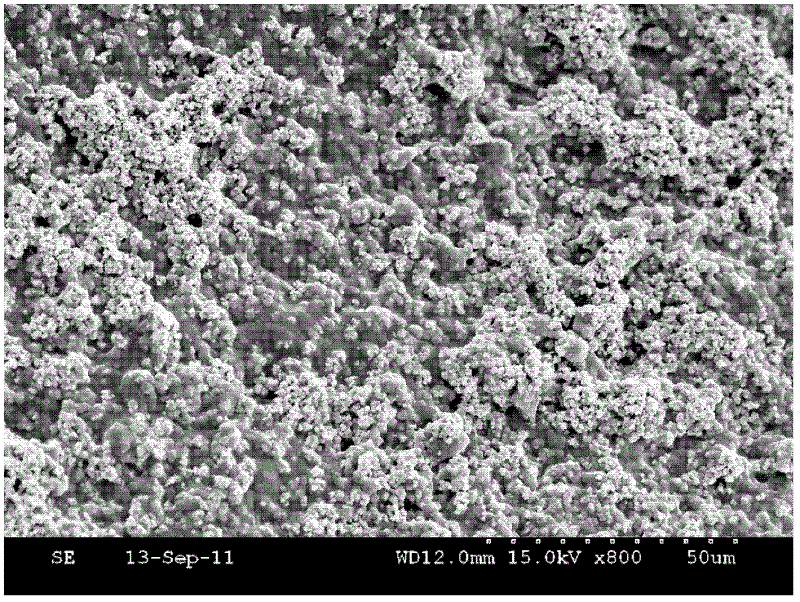

[0026] (1) For 4-6mm Al 2 o 3 The pellets are pretreated by first soaking in 1mol / L nitric acid solution for 12 hours, then soaking in 1mol / L NaOH solution for 12 hours to remove impurities, and then washing them repeatedly with deionized water until the rinse water is neutral. The washed carrier was dried in a drying oven at 60° C. for 12 hours, and placed in a desiccator for use.

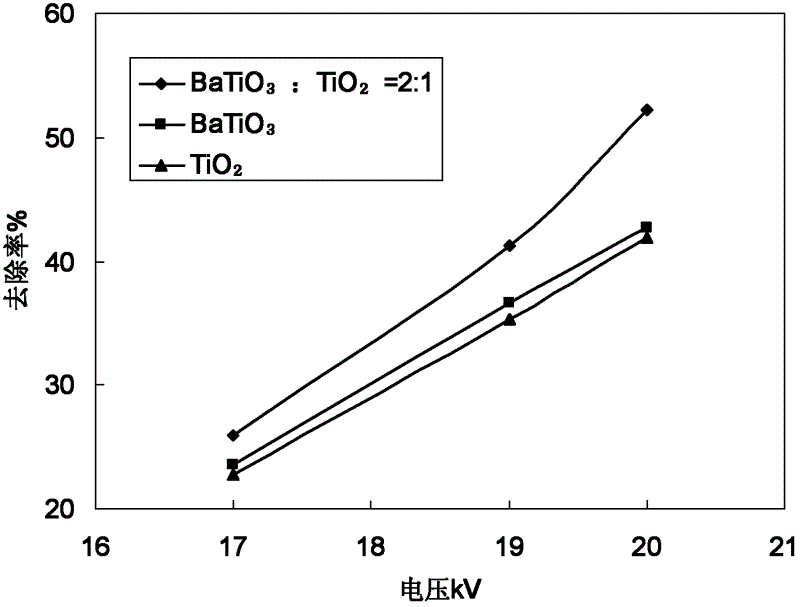

[0027] (2) Select nano-scale BaTiO with the same particle size range (20-60nm) 3 Powder 16.7g with nano TiO 2 8.3g of powder (mass ratio: 2:1) was placed in a mortar and repeatedly ground and then mixed.

[0028] (3) Take 25g of epoxy resin and 6ml of curing agent, put them in a beaker and stir. During the stirring process, 5ml of absolute ethanol was added to facilitate uniform mixing. After the resin is mixed, add the mixed powder prepared in step (2), and continue to stir to make the powder evenly dispersed in the colloidal liquid.

[0029] (4) The mixture is placed in an ultrasonic devic...

Embodiment 2

[0033] (1) For 4-6mm Al 2 o 3 The pellets are pretreated, soaked in 1.5mol / L nitric acid solution for 13 hours, then soaked in 1.5mol / L NaOH solution for 13 hours to remove impurities, and then washed repeatedly with deionized water until the rinse water is neutral . The washed carrier was dried in a drying oven at 60° C. for 12 hours, and placed in a desiccator for use.

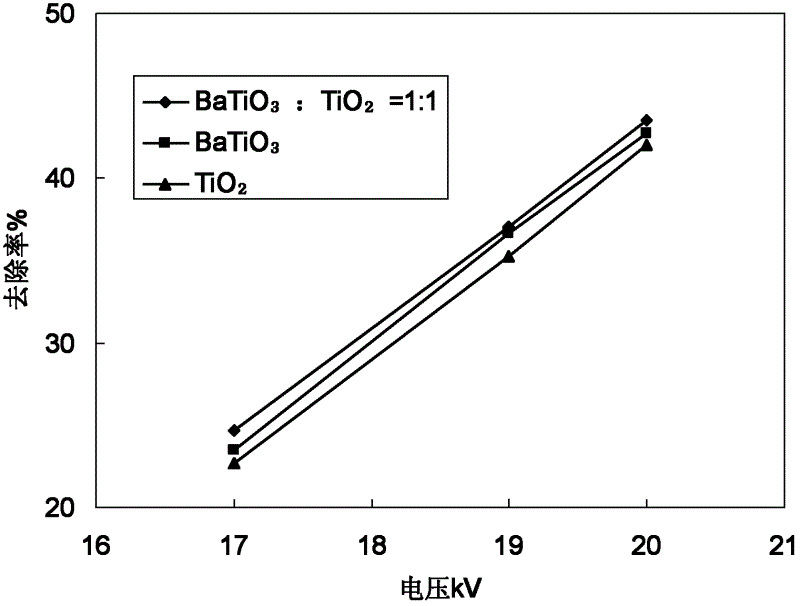

[0034] (2) Select nano-scale BaTiO with the same particle size range (20-60nm) 3 Powder 12.5g with nano TiO 2 12.5g of powder (mass ratio 1:1), put in a mortar and grind repeatedly and then mix.

[0035] (3) Take 25g of epoxy resin and 6ml of curing agent, put them in a beaker and stir. During the stirring process, 6ml of absolute ethanol was added to facilitate uniform mixing. After the resin is mixed, add the mixed powder prepared in step (2), and continue to stir to make the powder evenly dispersed in the colloidal liquid.

[0036](4) The mixture is placed in an ultrasonic device, and the ultrasoni...

Embodiment 3

[0040] (1) For 4-6mm Al 2 o 3 The pellets are pretreated by first soaking in 2mol / L nitric acid solution for 15 hours, then soaking in 2mol / L NaOH solution for 15 hours to remove impurities, and then washing them repeatedly with deionized water until the rinse water is neutral. The washed carrier was dried in a drying oven at 60° C. for 12 hours, and placed in a desiccator for use.

[0041] (2) Select nano-scale BaTiO with the same particle size range (20-60nm) 3 Powder 8.3g with nano TiO 2 16.7g of powder (mass ratio: 1:2), put in a mortar and grind repeatedly and then mix.

[0042] (3) Take 25g of epoxy resin and 6ml of curing agent, put them in a beaker and stir. During the stirring process, 7ml of absolute ethanol was added to facilitate uniform mixing. After the resin is mixed, add the mixed powder prepared in step (2), and continue to stir to make the powder evenly dispersed in the colloidal liquid.

[0043] (4) The mixture is placed in an ultrasonic device, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com