Macromolecule far-infrared electric heating cloth and heating system utilizing same

An infrared electricity and polymer technology, applied in the field of heating system, can solve the problems of no far-infrared radiant heat function, low electro-thermal conversion efficiency, powder falling off when the material encounters water, etc., achieving light weight, promoting blood circulation, and soft texture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Mix the following materials according to weight ratio to prepare slurry:

[0029] Acetylene black: conductive graphite: zirconia: titanium dioxide: tourmaline powder: ferric oxide: polyethylene: 108 glue: polytetrafluoroethylene emulsion = 23:17:10:10:5:10:5:10:10.

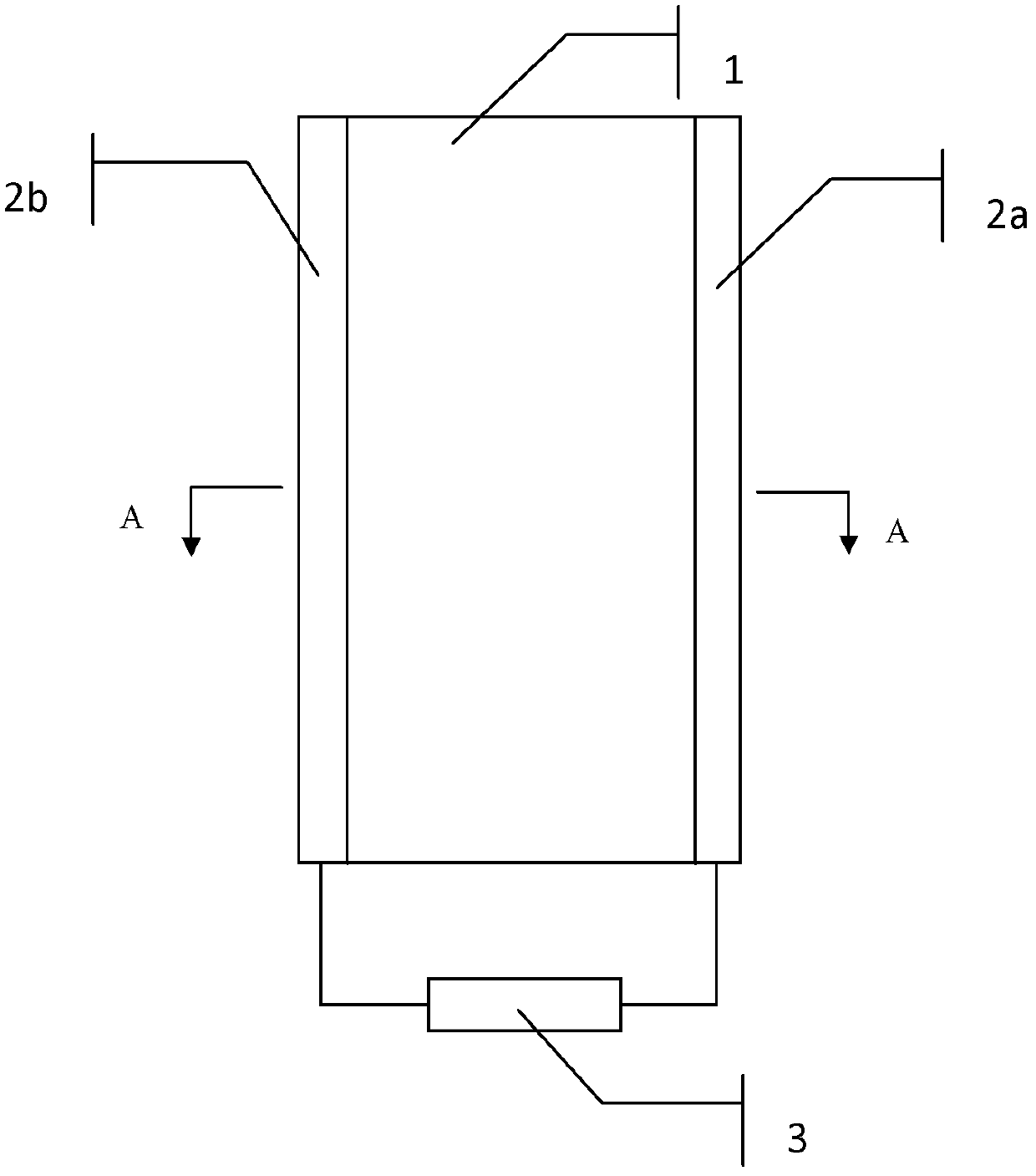

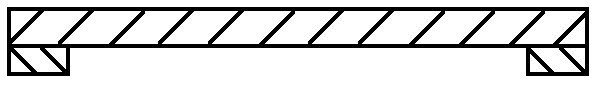

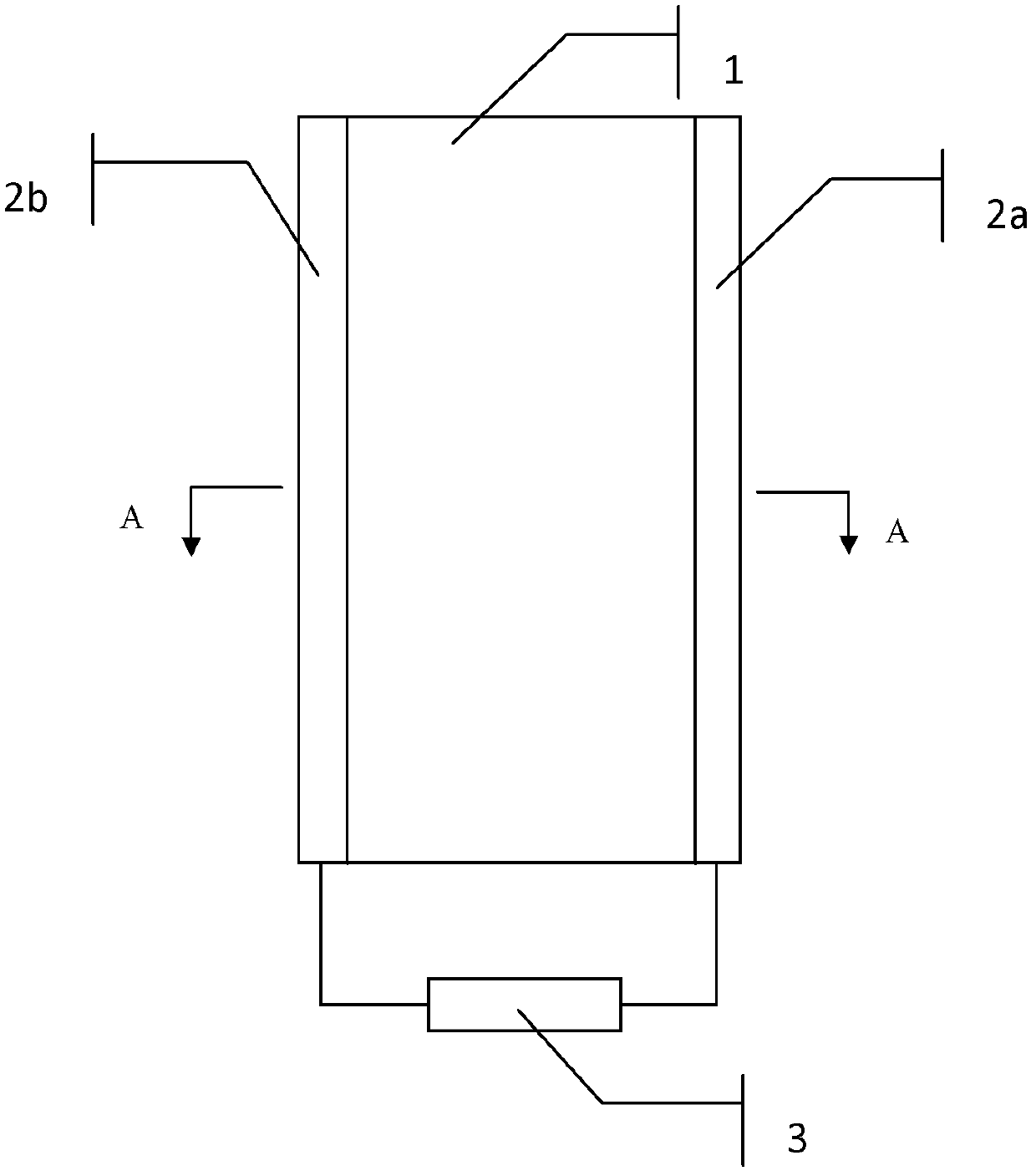

[0030] Then add 20% water to dilute, and stir fully and uniformly to make a slurry; then soak the pure cotton cloth (or non-woven fiber cloth) in the slurry (keep for 5 minutes); then put the cotton cloth that has sucked the slurry Take it out, dry it, and roll it to make an electrothermal cloth 1 with a certain resistance value; finally, apply conductive glue on both sides of the cloth, and then paste the copper foils 2a and 2b for compaction, and weld the leads on both ends. Ready to use.

[0031] It also includes: a lithium-ion battery pack 3, which is connected with the polymer electrothermal cloth. The battery pack is equipped with 3-5 switches for different temperature control, and each person can a...

Embodiment 2

[0033] Mix the following materials according to weight ratio to prepare slurry:

[0034] Acetylene black: conductive graphite: zirconia: titanium dioxide: tourmaline powder: ferric oxide: polyethylene: 108 glue: polytetrafluoroethylene emulsion = 17:23:7:8:5:10:10:10:10.

[0035] Then add 40% water to dilute, and stir fully and uniformly to make a slurry; then soak the pure cotton cloth (or non-woven fiber cloth) in the slurry (keep for 5 minutes); then put the cotton cloth that has sucked the slurry Take it out, dry it, and roll it to make an electrothermal cloth 1 with a certain resistance value; finally, apply conductive glue on both sides of the cloth, and then paste the copper foils 2a and 2b for compaction, and weld the leads on both ends. Ready to use.

[0036] It also includes: a lithium-ion battery pack 3, which is connected with the polymer electrothermal cloth. The battery pack is equipped with 3-5 switches for different temperature control, and each person can ad...

Embodiment 3

[0038] Mix the following materials according to weight ratio to prepare slurry:

[0039] Acetylene black: conductive graphite: zirconia: titanium dioxide: tourmaline powder: ferric oxide: polyethylene: 108 glue: polytetrafluoroethylene emulsion = 7: 18: 10: 10: 10: 10: 20: 5: 10.

[0040] Then add 20% water to dilute, and stir fully and uniformly to make a slurry; then soak the pure cotton cloth (or non-woven fiber cloth) in the slurry (keep for 5 minutes); then put the cotton cloth that has sucked the slurry Take it out, dry it, and roll it to make an electrothermal cloth 1 with a certain resistance value; finally, apply conductive glue on both sides of the cloth, and then paste the copper foils 2a and 2b for compaction, and weld the leads on both ends. Ready to use.

[0041] It also includes: a lithium-ion battery pack 3, which is connected with the polymer electrothermal cloth. The battery pack is equipped with 3-5 switches for different temperature control, and each pers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com