Surface modifying method for improving surface power function of indium tin oxide transparent conductive film

A technology of transparent conductive film and surface work function, which is applied in the direction of circuits, electrical components, electric solid devices, etc., can solve the problems of limited space, degradation, uncontrollable, etc., to improve luminous brightness and light efficiency, improve surface work function, The effect of prolonging the life of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

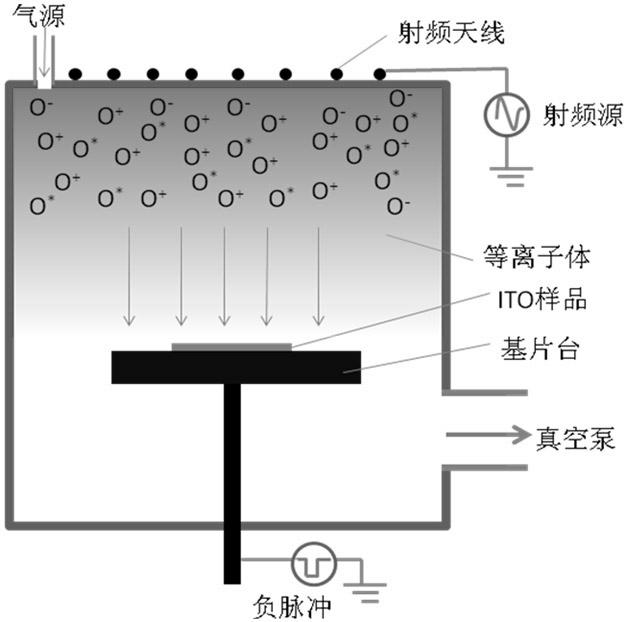

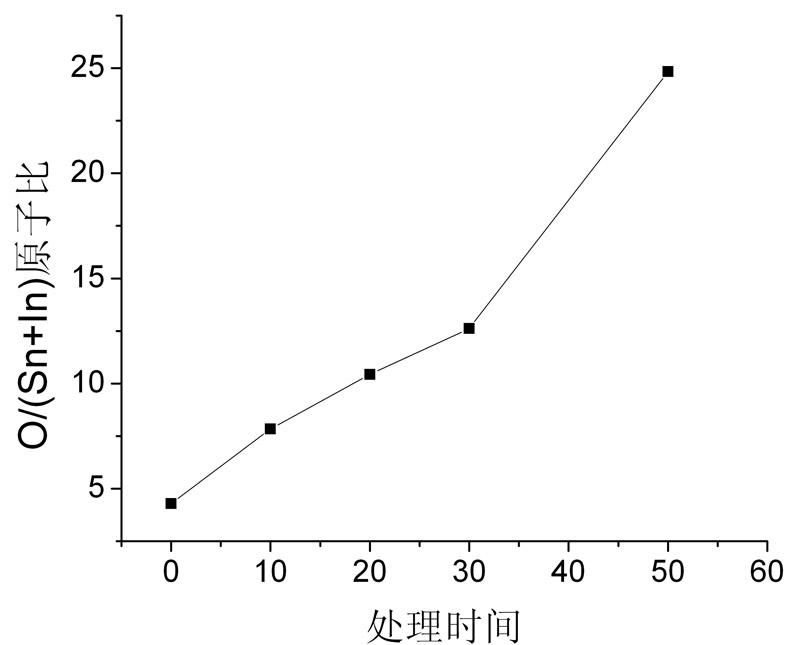

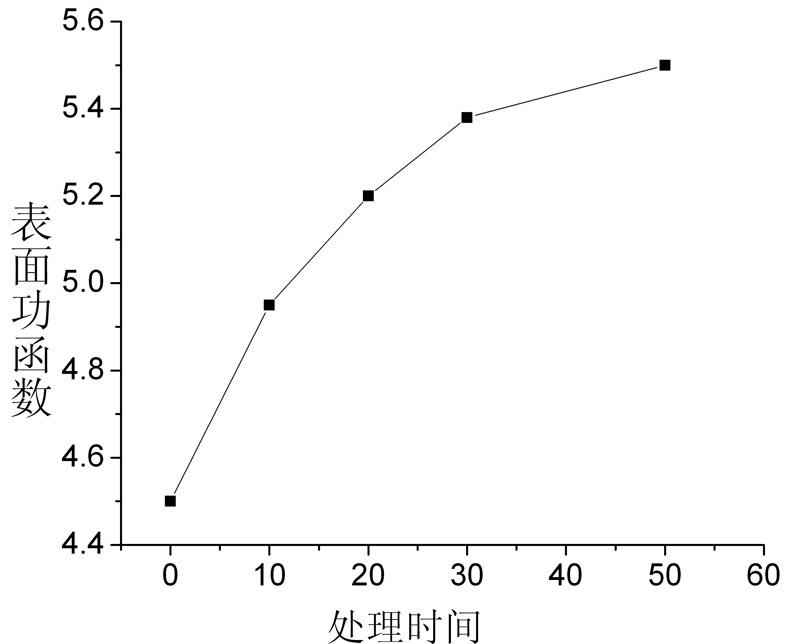

[0019] The present invention increases the ITO surface O / (Sn+In) atomic ratio by means of plasma immersion ion implantation, and improves the ITO surface work function to the matching level with the HOMO energy level of the HTL of the OLED device, and uses this high surface work function ITO As an anode to prepare an OLED device, the overall performance of the device can be improved, such as increased light efficiency and brightness, and extended life. The specific process includes oxygen plasma generation, ITO surface cleaning treatment, and ion implantation treatment. The specific operation steps are as follows:

[0020] 1. Clean the ITO surface by ultrasonic bath of acid and deionized water respectively, remove surface pollutants, and dry for later use.

[0021] 2. Put the cleaned and dried ITO on the horizontal substrate table in the vacuum chamber, with the ITO film upward, and close the vacuum chamber.

[0022] 3. Turn on the vacuum pump to pump air, and the background...

Embodiment 2

[0032] 1. Clean the ITO surface by ultrasonic bath of acid and deionized water respectively, remove surface pollutants, and dry for later use.

[0033] 2. Put the cleaned and dried ITO on the horizontal substrate table in the vacuum chamber, with the ITO film upward, and close the vacuum chamber.

[0034] 3. Turn on the vacuum pump to pump air, and the background vacuum reaches -3 Pa, fill the vacuum chamber with pure oxygen to >10 3 Pa dilute the background, turn off the oxygen, and pump again to -3 Pa.

[0035] 4. Inflate with oxygen, adjust the oxygen flow rate to 50 sccm, and adjust the valve of the vacuum pipeline to stabilize the air pressure at 5Pa.

[0036] 5. Turn on the radio frequency power supply and adjust the power to 200W. The radio frequency power is coupled from the quartz window directly above the substrate stage to the vacuum chamber through the mosquito-repellent coil antenna, and the gas discharge is excited to generate plasma. The substrate stage carryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com