Nickel oxide thin film and its preparation method, functional material, thin film structure manufacturing method and electroluminescent device

A technology of electroluminescent devices and thin film structures, applied in the direction of electric solid devices, nickel oxide/nickel hydroxide, electrical components, etc., can solve the problem that the surface work function of nickel oxide conductive thin films cannot meet the requirements of OLED devices and QLED devices, etc. Achieve the effect of improving hole injection rate, improving performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] In yet another typical embodiment of the present application, a method for preparing the above-mentioned nickel oxide film is provided, the preparation method comprising: placing a nickel oxide precursor solution on a carrier, performing the first annealing, and forming nickel oxide film layer; after the nickel oxide film layer is treated with ultraviolet-ozone, organic molecules are arranged on the surface of the nickel oxide film layer; and the nickel oxide film layer provided with organic molecules is annealed for the second time in nitrogen or inert gas atmosphere, Nickel oxide thin film

[0038] The nickel oxide precursor solution is annealed for the first time to obtain a nickel oxide film; then, through the ultraviolet-ozone treatment of the nickel oxide film, on the one hand, a layer of hydroxyl radicals is generated on the surface of the nickel oxide to provide On the other hand, clean the nickel oxide film layer to improve the binding force of organic molecule...

Embodiment 1

[0054] S1: Nickel nitrate and glycine were dissolved in water at a molar ratio of 3:5 to prepare a nickel oxide precursor solution, in which the concentration of nickel nitrate was 0.06 mol / L. The nickel oxide precursor was coated on the ITO substrate by spin coating (rotational speed: 4000rpm), and the nickel oxide precursor solution was annealed in air at 200° C. for 60 min to obtain a nickel oxide film.

[0055] S2: Treat the nickel oxide film layer with ultraviolet-ozone for 20 minutes, and the irradiation power of the ultraviolet lamp is 200W. 2 In an atmospheric glove box, a trifluoromethylbenzoic acid / ethanol solution with a concentration of 3mmol / L was spin-coated on the ITO / nickel oxide composite film (rotating speed: 2000rpm).

[0056] S3: In the glove box, place the above film on a heating panel, anneal at 120°C for 30 minutes, then wash the surface three times with ethanol, and dry to obtain a nickel oxide film, that is, a surface-modified ITO / nickel oxide composit...

Embodiment 2

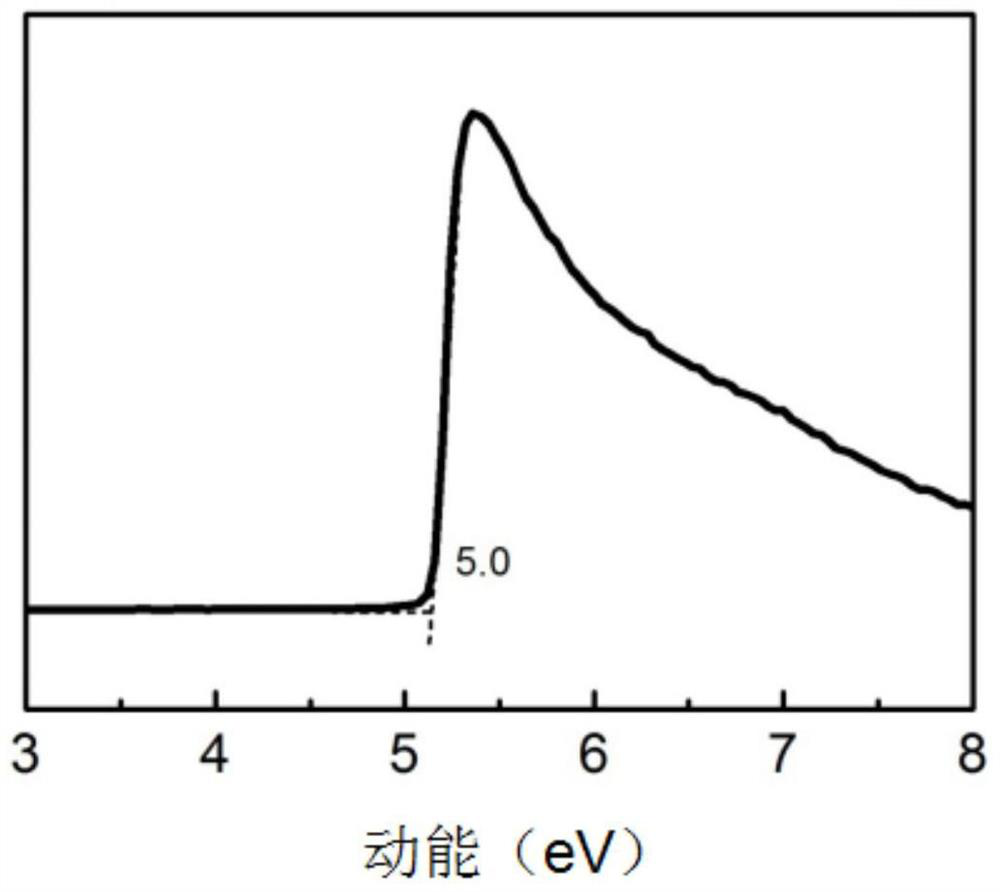

[0058] The specific steps, materials and instruments used are the same as those in Example 1, except that the annealing temperature in step S3 is 140°C. The thin film is tested by ultraviolet photoelectric spectroscopy, and the test results are shown in image 3 , In this embodiment, the surface work function of ITO / nickel oxide is 5.7eV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron work function | aaaaa | aaaaa |

| electron work function | aaaaa | aaaaa |

| electron work function | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com