Preparation method of film temperature sensor for liquid floated gyroscope

A thin-film temperature and liquid floating gyroscope technology, which is applied in the direction of instruments, thermometers, scientific instruments, etc., can solve the problems of difficult substrate processing, gyroscope measurement, no related reports, and low mechanical strength, so as to achieve solid structure and good film-base bonding force , the effect of short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

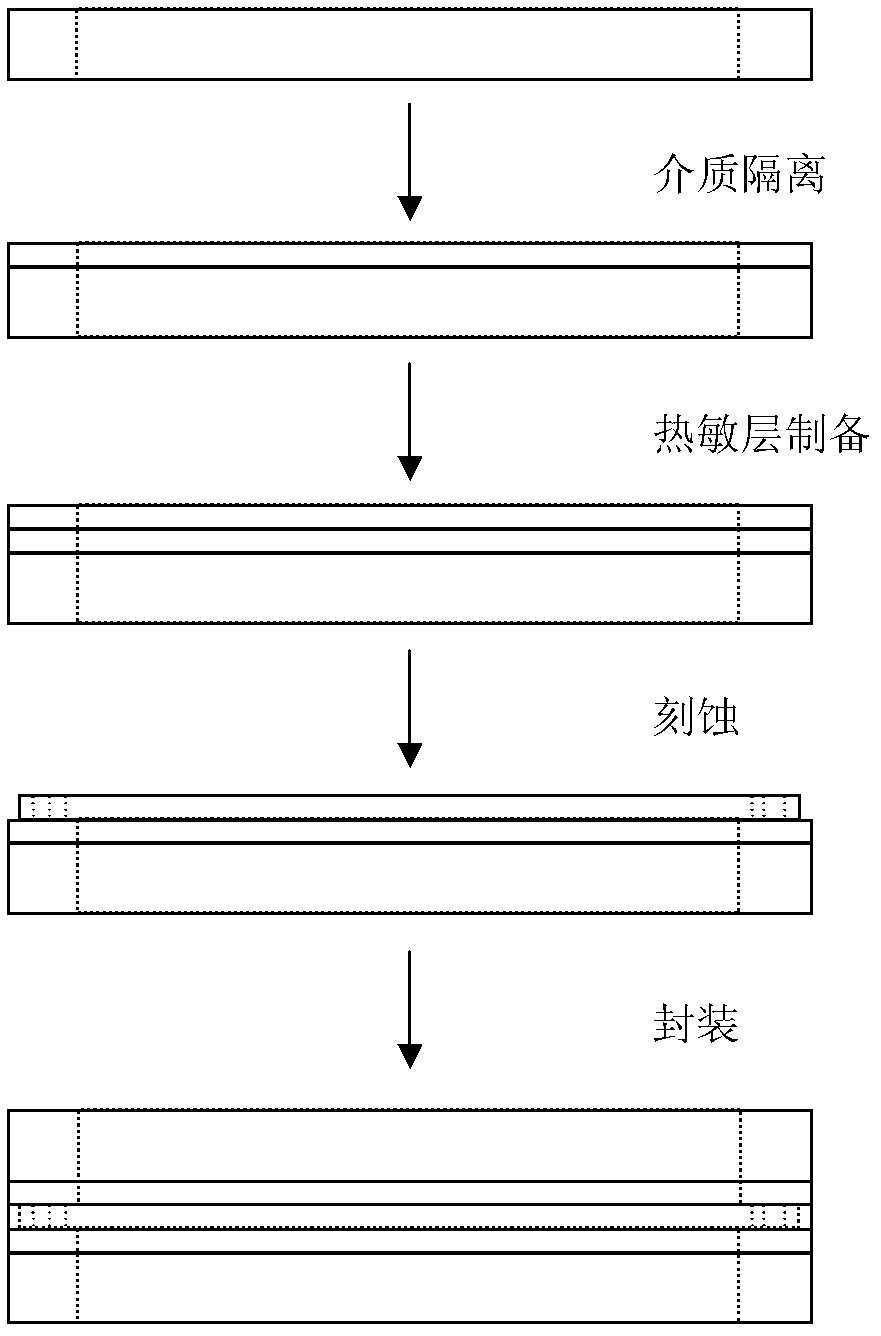

Method used

Image

Examples

specific Embodiment approach 1

[0022] (1) Using 7075 aluminum alloy as raw material, cut it into a ring with an outer diameter of 50mm, an inner diameter of 42mm, and a thickness of 1.5mm; the chemical composition of the 7075 aluminum alloy sample is as follows:

[0023]

[0024] (2) The aluminum alloy rings are gradually polished with 2000# and 3000# sandpaper, followed by degreasing in acetone and absolute ethanol, washing with alkali, pickling, washing with deionized water, and drying. Among them, alkaline washing solution: NaOH (30g / L), Na 2 CO 3 (20g / L), pickling solution: HNO 3 (12ml / L).

[0025] (3) Using MAO 60H-11 micro-arc oxidation power supply, in KOH and Na 2 SiO 3 The micro-arc oxidation process is carried out in the mixed electrolyte, where the frequency f=600Hz, the duty ratio Φ=8%, the temperature of the electrolyte during the reaction process is maintained below 40°C, the experimental voltage is set as shown in the table below, and the reaction time is 10min to obtain Al-based al ...

specific Embodiment approach 2

[0035] (1) Using 2024 aluminum alloy as raw material, cut it into a ring with an outer diameter of 50mm, an inner diameter of 42mm, and a thickness of 1.5mm; the chemical composition of the 2024 aluminum alloy sample is as follows:

[0036]

[0037]

[0038] (2) The aluminum alloy rings are gradually polished with 2000# and 3000# sandpaper, followed by degreasing in acetone and absolute ethanol, washing with alkali, pickling, washing with deionized water, and drying. Among them, alkaline washing solution: NaOH (30g / L), Na 2 CO 3 (20g / L), pickling solution: HNO 3 (12ml / L).

[0039] (3) Using MAO 60H-11 micro-arc oxidation power supply, in KOH and Na 2 SiO 3 The micro-arc oxidation process is carried out in the mixed electrolyte, where the frequency f = 600Hz, the duty cycle Φ = 8%, the temperature of the electrolyte during the reaction process is maintained below 40°C, the experimental voltage is set as shown in the table below, and the reaction time is 15min. Al 2 ...

specific Embodiment approach 3

[0047] (1) Using 2024 aluminum alloy as raw material, cut it into a ring with an outer diameter of 50mm, an inner diameter of 42mm, and a thickness of 1.5mm; the chemical composition of the 2024 aluminum alloy sample is as follows:

[0048]

[0049] (2) The aluminum alloy rings are gradually polished with 2000# and 3000# sandpaper, followed by degreasing in acetone and absolute ethanol, washing with alkali, pickling, washing with deionized water, and drying. Among them, alkaline washing solution: NaOH (30g / L), Na 2 CO 3 (20g / L), pickling solution: HNO 3 (12ml / L).

[0050] (3) Using MAO 60H-11 micro-arc oxidation power supply, in KOH and Na 2 SiO 3 The micro-arc oxidation process is carried out in the mixed electrolyte, where the frequency f = 600Hz, the duty cycle Φ = 8%, the temperature of the electrolyte during the reaction process is maintained below 40°C, the experimental voltage is set as shown in the table below, and the reaction time is 15min. Al 2 o 3 Membran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com