Forming process for fine line circuit with line width being below 0.05mm of flexible printed circuit board

A flexible printing and molding process technology, which is applied in the direction of removing conductive materials by chemical/electrolytic methods, can solve the problem that the process capability is difficult to meet the wiring requirements of IC packaging flexible substrates, and achieve low cost, high pass rate, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

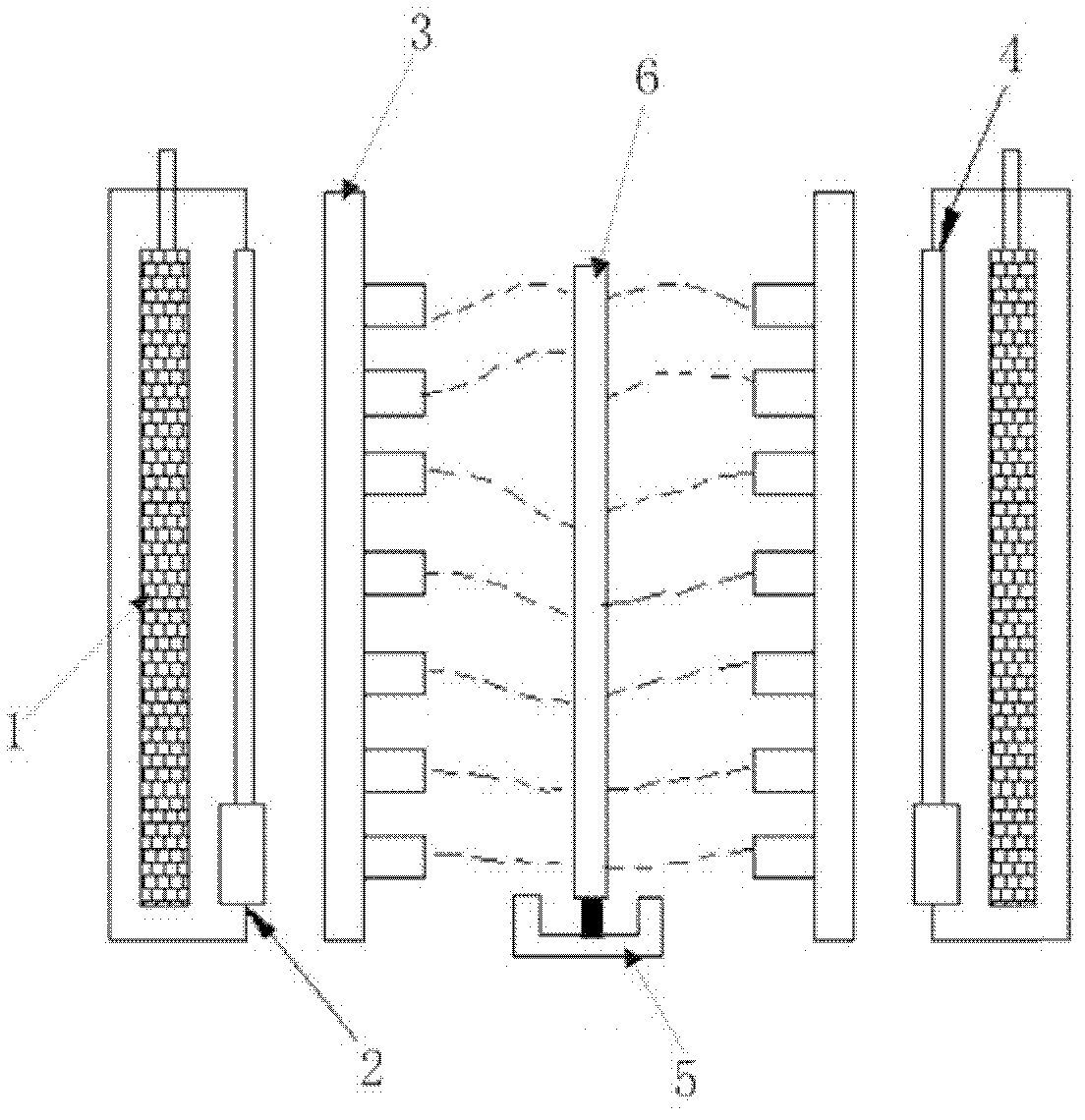

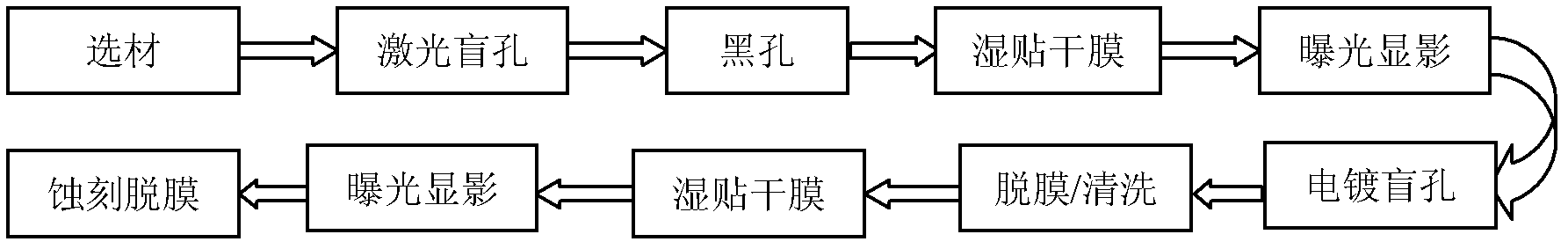

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The flexible printed circuit board forming process of the present invention, the process flow is: material selection, laser blind hole, black hole, wet paste dry film, exposure and development, electroplating blind hole, stripping cleaning, wet paste dry film again, exposure and development again, Etched lines. Such as image 3 As shown, the specific steps are:

[0019] 1. Material selection. Copper-clad base material with copper thickness of 9um on both sides and polyimide PI thickness of 20um in the middle is used. The overall size is 250×250-100mm in length, 1 piece. In this embodiment, it is 250×250mm in length.

[0020] 2. Laser drilling blind holes. According to the existing technology, laser drilling blind holes is used on the copper-clad substrate. The hole depth is to drill through the upper copper and the middle PI, and the hole diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com