Ramie abrasive base cloth

A base fabric, ramie technology, applied in the direction of fabrics, textiles, textiles and papermaking, etc., can solve the problems of low strength and wear resistance of fabric fibers, and achieve the effects of avoiding accumulation, good durability and fast heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

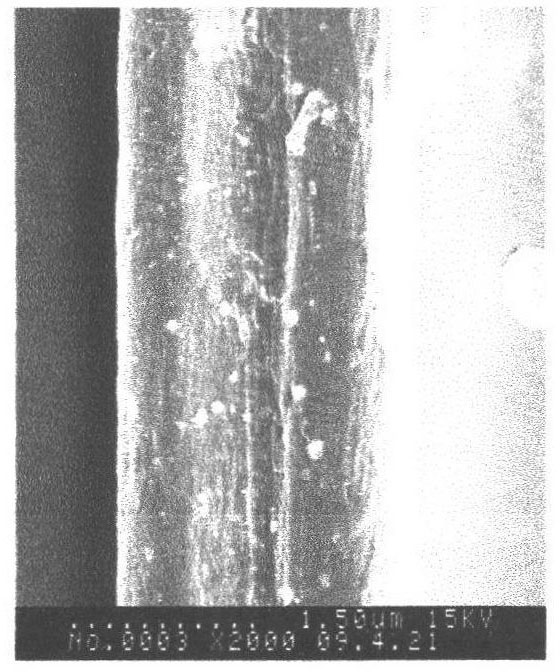

Image

Examples

Embodiment 1

[0022] 48Nm×48Nm×72×68×63 R95 / 316L 5 (ramie fiber with 95% fiber content; 5% 316L) grinding base cloth.

[0023] Adopt the ramie fiber of 1600-2000Nm, the length of ramie fiber is 60-240 and 316L, 6.5umm * 90 stainless steel fiber traction-cut strands are blended, spun into 48Nm long-fiber blended yarn, and then weaved into cloth.

[0024] We use the CZ304A high-speed needle carding machine for combining, and adopt the process of starting to mix strips at the same time. The fiber content is 95% ramie long fiber and 5% 316L stainless steel long fiber. The ramie fiber strips are designed to feed 11 pieces, and the wet weight of each strip is 8.42 g / m. The 316L stainless steel long fiber strips are designed to be fed into one piece. The weight of the stainless steel long fiber strips is 5 g / m. The first process of merging and mixing is carried out on the model. The first merging and mixing process is as follows: the number of strikes on the needle plate is 852 times / min; the to...

Embodiment 2

[0035] 48Nm×48Nm×85×68×63 R95 / 316L 5 jacquard grinding base fabric.

[0036] Spinning process is as embodiment 1

[0037] In order to improve the friction coefficient of the base fabric, we designed a jacquard base fabric, and the warp and weft yarns are all made of 48Nm ramie long fiber and stainless steel long fiber blended spun yarn. The weaving warp density is designed to be 335 threads / 10cm, the weft density is 268 threads / 10cm, and the cloth width is 63". example 1.

[0038] Reeding process: the reed number is 82.5 #, reeding width 165cm, brown frame 9 pages,

[0039] Healds: 882 pieces on pages 1 and 2, 930 pieces on pages 3 and 4, and 144 pieces on pages 5, 6, 7, 8, and 9.

[0040] Denting: ground organization: (1 2 3 4) × 8 times

[0041] (5 6 7 8 9 3 9 8 7 6 5 4)×1 time

[0042] (1 2 3 4)×16 times

[0043] (5 6 7 8 9 3 9 8 7 6 5 4)×1 time

[0044] A total of 120 / cycle (2 into)

[0045] Side organizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com