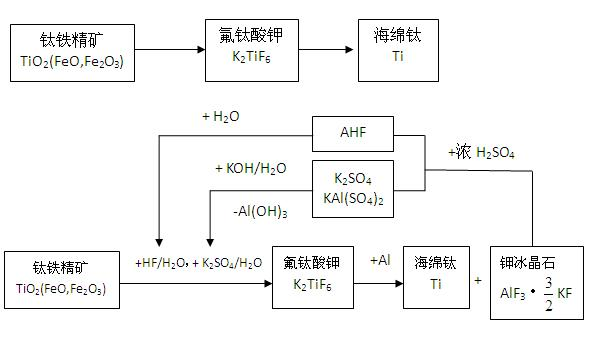

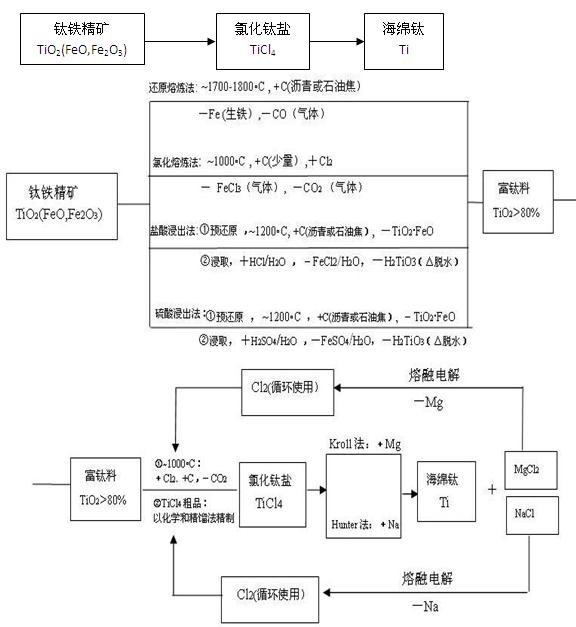

Recycling preparation method for producing titanium sponge and co-producing potassium cryolite with potassium fluotitanate as intermediate raw material

A technology of potassium fluorotitanate and potassium cryolite, which is applied in the direction of aluminum fluoride, alkali metal fluoride, and improvement of process efficiency, can solve the problems of unfavorable environmental protection, harsh reaction conditions, and high production cost of chlorine gas, and achieve full realization Recycling, short production cycle, and the effect of reducing the overall cost of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Put 1 ton of ilmenite concentrate powder in a reaction kettle, add 1.5 tons of hydrofluoric acid with a volume fraction of 30%, and fully react at 120°C to generate fluorotitanic acid. After the fluorotitanic acid is cooled, add the mass fraction 4 tons of 10% potassium sulfate solution, react fully to form potassium fluotitanate precipitate, centrifuge, rinse, dry to obtain potassium fluotitanate, weigh; put potassium fluotitanate in another reactor, vacuumize Introduce argon protection, heat up to 800°C, slowly drop aluminum liquid into the reactor according to the reaction ratio, stir rapidly, react for 5 hours, and generate sponge titanium and potassium cryolite, open the reactor cover, and use a siphon pump to pump out the potassium in the upper layer Cryolite, the titanium sponge in the lower layer is purified by vacuum distillation at 1000°C to obtain purified titanium sponge; after cooling, the potassium cryolite is crushed, weighed, and concentrated sulfuric aci...

Embodiment 2

[0027] Put 1 ton of ilmenite concentrate powder in a reaction kettle, add 1.5 tons of hydrofluoric acid with a volume fraction of 30%, and fully react at 120°C to generate fluorotitanic acid. After the fluorotitanic acid is cooled, add the mass fraction 4 tons of 10% potassium sulfate solution, fully reacted to form potassium fluotitanate precipitate, centrifuged, rinsed, dried to obtain potassium fluotitanate, weighed; weighed aluminum according to the reaction ratio and put it in another reactor, vacuumized Afterwards, the argon gas protection was introduced, and the temperature was raised to 800°C. Add dried potassium fluorotitanate into the reactor, stir rapidly, and react for 5 hours to generate sponge titanium and potassium cryolite. Open the reactor cover, and use a siphon pump to draw out the upper layer Potassium cryolite, the sponge titanium in the lower layer is purified by vacuum distillation at 1000°C to obtain purified sponge titanium; the potassium cryolite is br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com