Performance-controllable epoxy-polyketone grouting material as well as preparation method and application thereof

A grouting material, epoxy technology, applied in soil protection, protection devices, marine engineering and other directions, can solve the problems of increased mechanical properties, limited irrigability, short irrigating time, etc., and achieves low initial viscosity and spreadability. Strong, permeable and controllable effect of operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

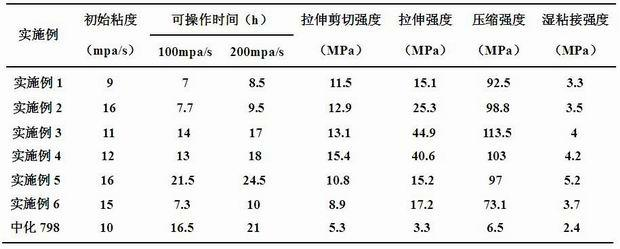

Examples

Embodiment 1

[0023] Mix 45 parts of epoxy resin E-51, 23 parts of butanone, 31.8 parts of benzaldehyde, and 0.2 parts of aluminate coupling agent to obtain component A; mix 45 parts of ethylenediamine, curing regulator T 48 parts of -31, 5 parts of 2,4,6-tris(dimethylaminomethyl)phenol, 2 parts of calcium oxide, stirring and mixing to obtain component B; mix component A and component B according to the weight ratio of 100:5 The epoxy-polyketone grouting material is uniformly obtained.

Embodiment 2

[0025] Stir and mix 10 parts of epoxy resin E-44, 44 parts of acetone, 45.5 parts of paraformaldehyde, and 0.5 parts of titanate coupling agent to obtain component A; 88.5 parts of triethylenetetramine, 651 parts of curing regulator # 7 parts, 3 parts of 2,4,6-tris(dimethylaminomethyl)phenol, 1.5 parts of phosphazene and stir and mix to obtain component B; mix component A and component B according to the weight ratio of 100:0.5 An epoxy-polyketone grouting material was obtained.

Embodiment 3

[0027] Stir and mix 90 parts of epoxy resin E-51, 7 parts of cyclohexanone, 22.5 parts of benzaldehyde, and 0.5 parts of silane coupling agent KH550 to obtain component A; mix 80 parts of m-phenylenediamine, curing regulator ketone 10 parts of imine, 5 parts of 2,4,6-tris(dimethylaminomethyl)phenol, and 5 parts of thiosemicarbazide were stirred and mixed to obtain component B; the weight ratio of component A and component B was 100:70 Mix evenly to obtain epoxy-polyketone grouting material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com