Modified epoxy emulsion and preparation method thereof

A technology of epoxy emulsion and modification, applied in the direction of coating, etc., can solve the problems of poor compatibility between epoxy resin and emulsifier, unsatisfactory flexibility and water resistance of the coating film, and unsatisfactory use performance, etc., to achieve Excellent physical and mechanical properties, improved coating film quality, and good film-forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

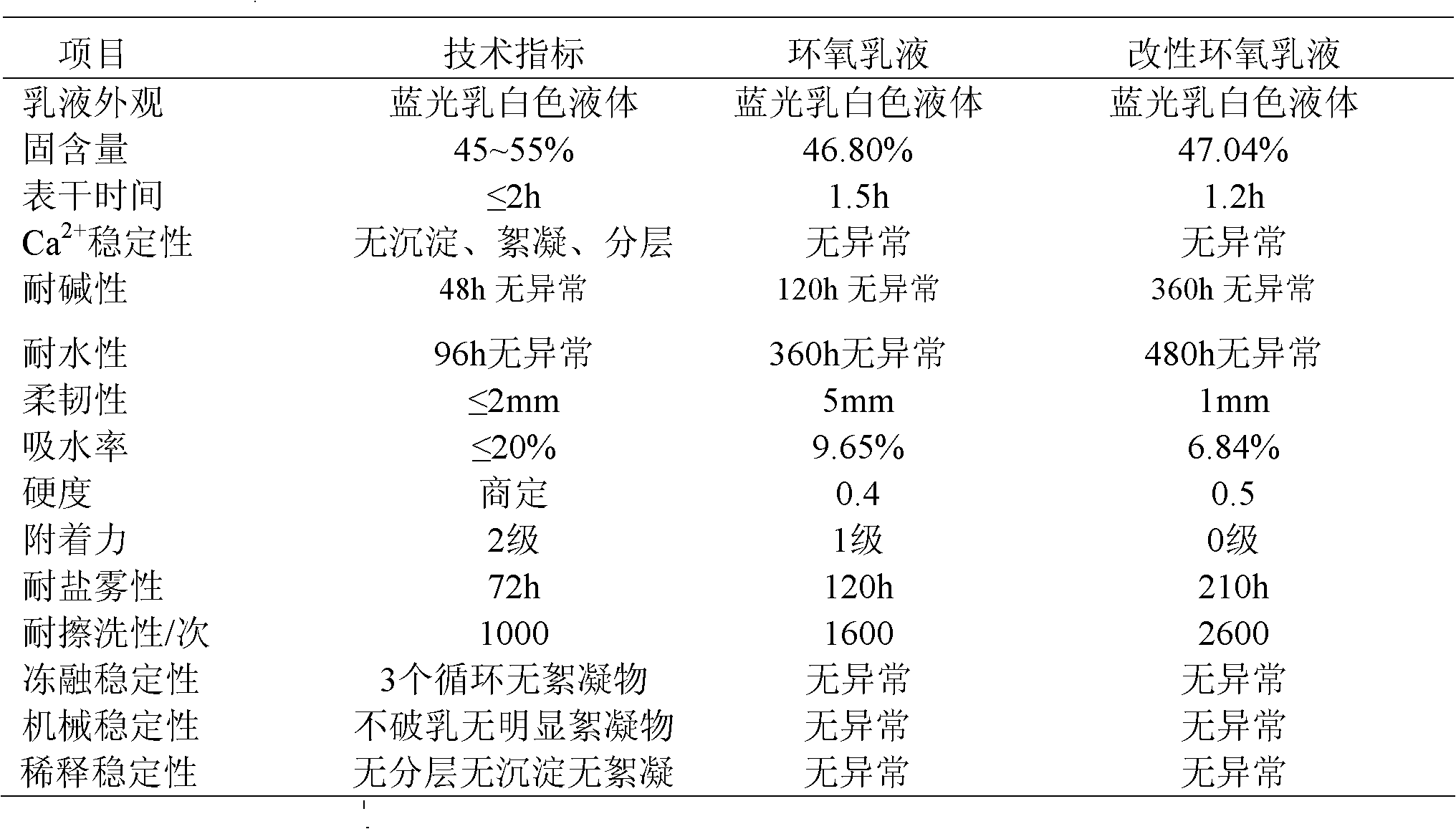

Examples

Embodiment 1

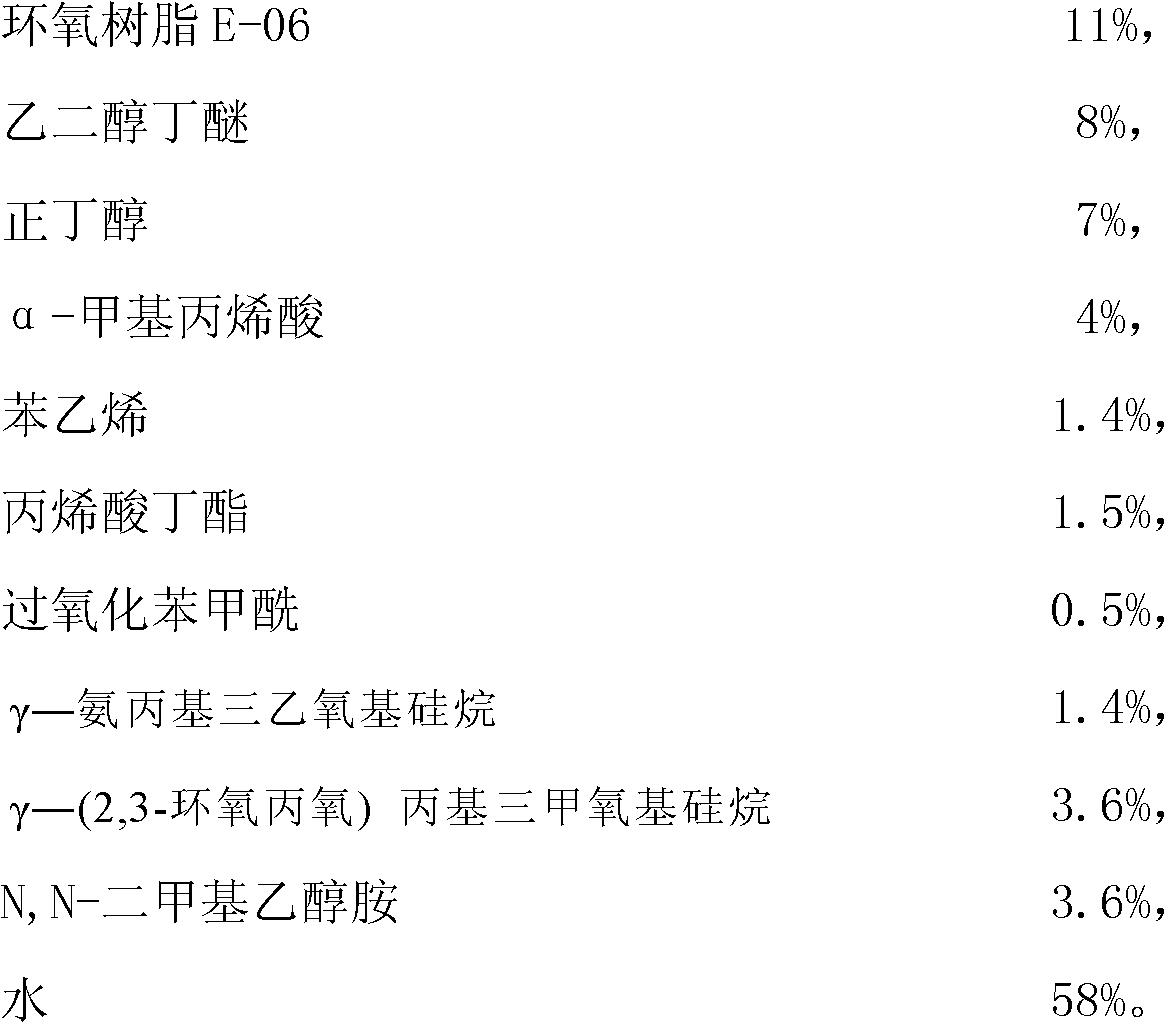

[0015] 1. Weigh each component according to mass percentage

[0016]

[0017] 2. Preparation method

[0018] 1. Preparation of graft copolymer, respectively add α-methacrylic acid, butyl acrylate, styrene and benzoyl peroxide into the reaction vessel and mix evenly. After the dissolution is complete, ultrasonically shake for 25 minutes to discharge;

[0019] 2. Add epoxy resin E-06, ethylene glycol butyl ether and n-butanol into the reaction vessel and mix evenly. The temperature rises to 110°C. After the dissolution is complete, add the graft copolymer obtained in step 1 dropwise within 90 minutes at a constant speed , stirred at a medium speed, kept warm for 150 minutes, lowered the temperature to 58°C, added a mixture of γ-(2,3-glycidoxy)propyltrimethoxysilane and γ-aminopropyltriethoxysilane, kept warm Reaction 60min;

[0020] 3. After the reaction is complete, lower the temperature to 38°C, neutralize with N,N-dimethylethanolamine until the pH value is 7-8, add water...

Embodiment 2

[0025] 1. Weigh each component according to mass percentage

[0026]

[0027]

[0028] 2. Preparation method

[0029] 1. Preparation of graft copolymer, respectively add α-methacrylic acid, butyl acrylate, styrene and benzoyl peroxide into the reaction vessel and mix evenly. After the dissolution is complete, ultrasonically shake for 24 minutes to discharge;

[0030] 2. Add epoxy resin E-06, ethylene glycol butyl ether and n-butanol into the reaction vessel and mix evenly. The temperature rises to 108°C. After the dissolution is complete, add the graft copolymer obtained in step 1 dropwise at a constant speed within 88 minutes. Stir at medium speed, heat preservation reaction, 148min, lower the temperature to 57°C, add γ-(2,3-glycidoxy)propyltrimethoxysilane and γ-aminopropyltriethoxysilane mixture , heat preservation reaction, 58min;

[0031] 3. After the reaction is complete, lower the temperature to 36°C, neutralize with N,N-dimethylethanolamine until the pH value i...

Embodiment 3

[0036] 1. Weigh each component according to mass percentage

[0037]

[0038] 2. Preparation method

[0039] 1. Preparation of graft copolymer, respectively add α-methacrylic acid, butyl acrylate, styrene and benzoyl peroxide into the reaction vessel and mix evenly. After the dissolution is complete, ultrasonically shake for 26 minutes to discharge;

[0040] 2. Add epoxy resin E-06, ethylene glycol butyl ether and n-butanol into the reaction vessel and mix evenly. The temperature rises to 109°C. After the dissolution is complete, add the graft copolymer obtained in step 1 dropwise at a constant speed within 89 minutes. Stir at medium speed, keep warm for 149 minutes, lower the temperature to 59°C, add γ-(2,3-glycidoxy)propyltrimethoxysilane and γ-aminopropyltriethoxysilane mixture , heat preservation reaction, 59min;

[0041] 3. After the reaction is complete, lower the temperature to 37°C, neutralize with N,N-dimethylethanolamine until the pH value is 7-8, add water to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com