Room temperature self-crosslinking acrylic ester emulsion

An acrylate and self-crosslinking technology, applied in the field of polymers, can solve the problems of imine side reaction curing time, affect the application effect of emulsion, etc., and achieve good balance, good wear resistance and good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

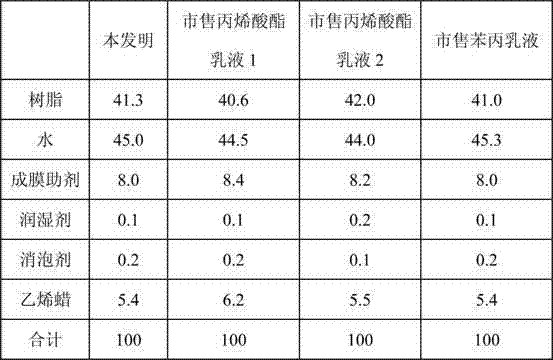

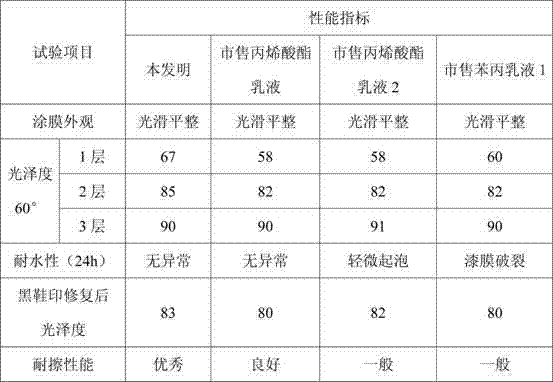

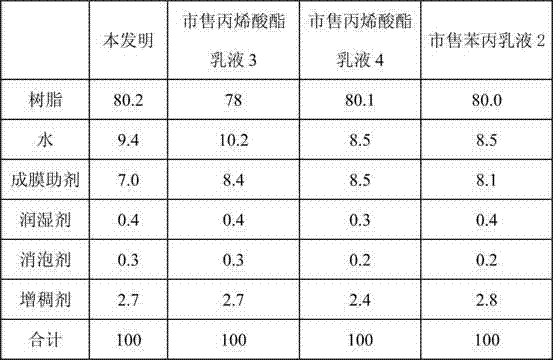

Examples

Embodiment 1

[0042] Add 536 grams of deionized water, 5 grams of sodium lauryl sulfate, 10 grams of disodium salt of fatty alcohol polyoxyethylene ether succinic sulfonate, and 3 grams of secondary alcohol ethoxylate into the reaction kettle, start stirring, and mix evenly. Heat to 40°C.

[0043] 50 grams of n-butyl acrylate, 60 grams of methacrylic acid, 175 grams of styrene, 55 grams of n-butyl methacrylate and 15 grams of N-methylolacrylamide were placed in a beaker and stirred evenly.

[0044] Add 3 grams of potassium persulfate to the reaction kettle, then add 20% monomer mixture and 1 gram of cumene hydroperoxide, and stir for 10 minutes.

[0045] Add 5.5 grams of sodium dodecyl diphenyl ether disulfonate to the remaining monomer mixture, and stir evenly. Continue to add dropwise to the reaction kettle, and the dropwise addition is completed in about 2 hours. Then, after incubating at 85° C. for 1 hour, 0.5 g of sodium persulfate was added dropwise, and the dropwise was completed i...

Embodiment 2

[0048] Add 200 grams of deionized water and 10 grams of fatty alcohol polyoxyethylene ether sodium sulfate into the reaction kettle, start stirring and mixing evenly, and heat to 80°C.

[0049] 10 grams of fatty alcohol polyoxyethylene ether sodium sulfate, 10 grams of methacrylic acid, 15 grams of acrylic acid and 350 grams of n-butyl methacrylate and 5 grams of diacetone acrylamide, 40 grams of methyl methacrylate, 10 grams of 1, 4-butanediol diacrylate was placed in a beaker, and stirred evenly to obtain a stable pre-emulsion.

[0050] Dissolve 1.5 grams of ammonium persulfate in 300 grams of deionized water to obtain an aqueous solution of ammonium persulfate, add 10% into the reaction kettle, then add 10% of the pre-emulsion, and stir for 5 minutes.

[0051] Add the remaining pre-emulsion and initiator solution dropwise to the reaction kettle, and finish dropping in 100 minutes. Then keep it warm at 82°C for 1.5h.

[0052]Cool down to 30°C, add 5 grams of ammonia water ...

Embodiment 3

[0054] Add 415.7 grams of deionized water, 25 grams of sodium dodecyl diphenyl ether disulfonate, 5 grams of fatty alcohol polyoxyethylene ether ammonium sulfate, and 5 grams of secondary alcohol ethoxylate into the reaction kettle, start stirring, and mix evenly , heated to 60°C.

[0055] 100 grams of n-butyl acrylate, 40 grams of ethyl acrylate, 200 grams of methyl methacrylate, 50 grams of methacrylic acid, 5 grams of glycidyl methacrylate, and 1 g of vinyl triethoxysilane were placed in a beaker, Stir to obtain a homogeneous monomer mixture.

[0056] 100 g of deionized water, 20 g of ethanolamine, 15 g of ammonium bicarbonate and 15 g of zinc oxide were mixed and stirred for 1 hour to obtain a clear zinc oxide solution.

[0057] Add 0.5 g of ammonium persulfate and 0.5 g of sodium persulfate into the reaction kettle, drop the monomer mixture for 2 hours, add 0.3 g of tert-butyl hydroperoxide into the reaction kettle after dropping the monomer, adjust the reaction temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com