Rare earth doped oxyfluoride tellurite scintillation glass and preparation method thereof

A technology of oxyfluorine tellurite and scintillation glass, which is applied in the field of scintillation glass, can solve problems such as high refractive index, achieve high density, low production cost, and good short-wavelength transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

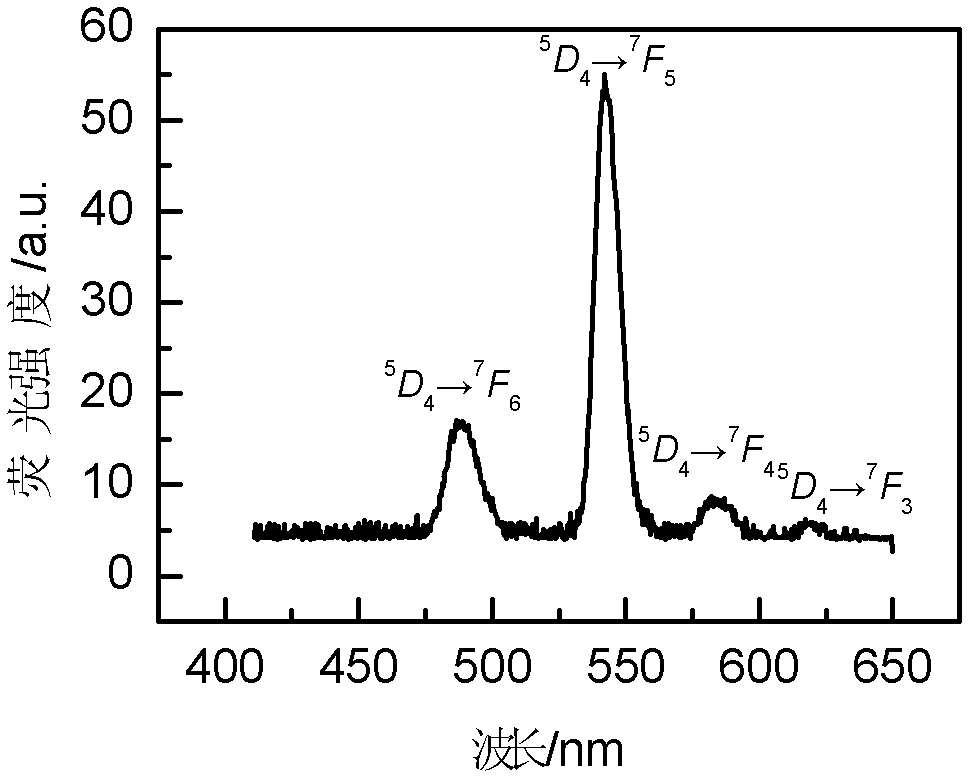

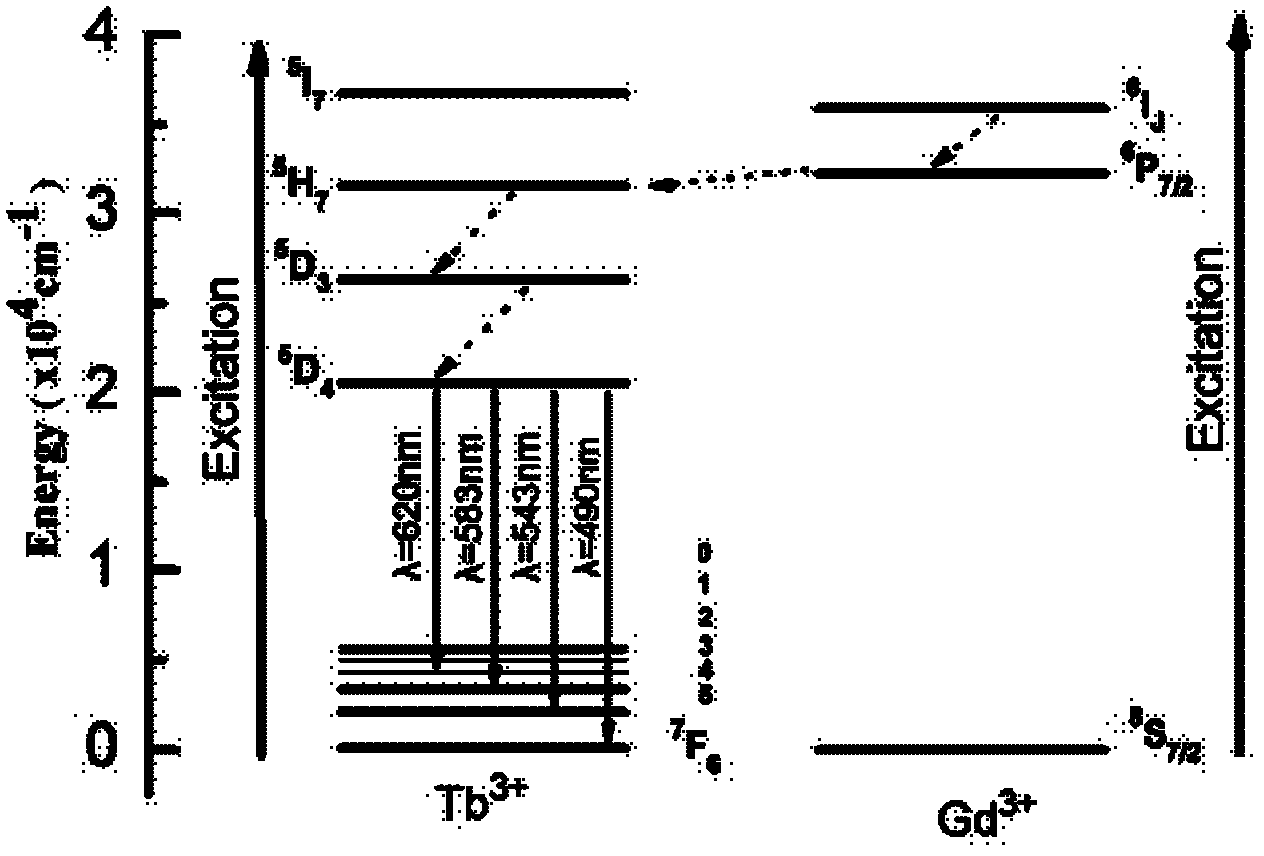

[0027] Preparation of rare earth doped oxyfluoride tellurate scintillation glass: according to raw material composition: TeO 2 : 65 mol%, PbF 2 : 15 mol%, BaF 2 : 7 mol%, Gd 2 o 3 : 6 mol%, Tb 2 o 3 : 7 mol%, weigh each raw material of analytical purity, mix all the raw materials evenly; then pour into a platinum crucible to melt into a melt, the melting temperature is 800-950°C, keep it warm for 0.5-2 hours after melting; pour the melt into Put it into a cast iron mold preheated at 200-300°C, and cool naturally to form glass; place the glass in a muffle furnace for annealing, annealing conditions: first heat the glass at 325-375°C for 1 hour, then heat Cool down to 45-55°C at a rate of 1 hour, then turn off the power supply of the muffle furnace and automatically cool down to room temperature to obtain the first product of scintillating glass, which is processed into 15×15×7mm after cutting, surface grinding and polishing, and becomes the scintillating glass of the pr...

Embodiment 2

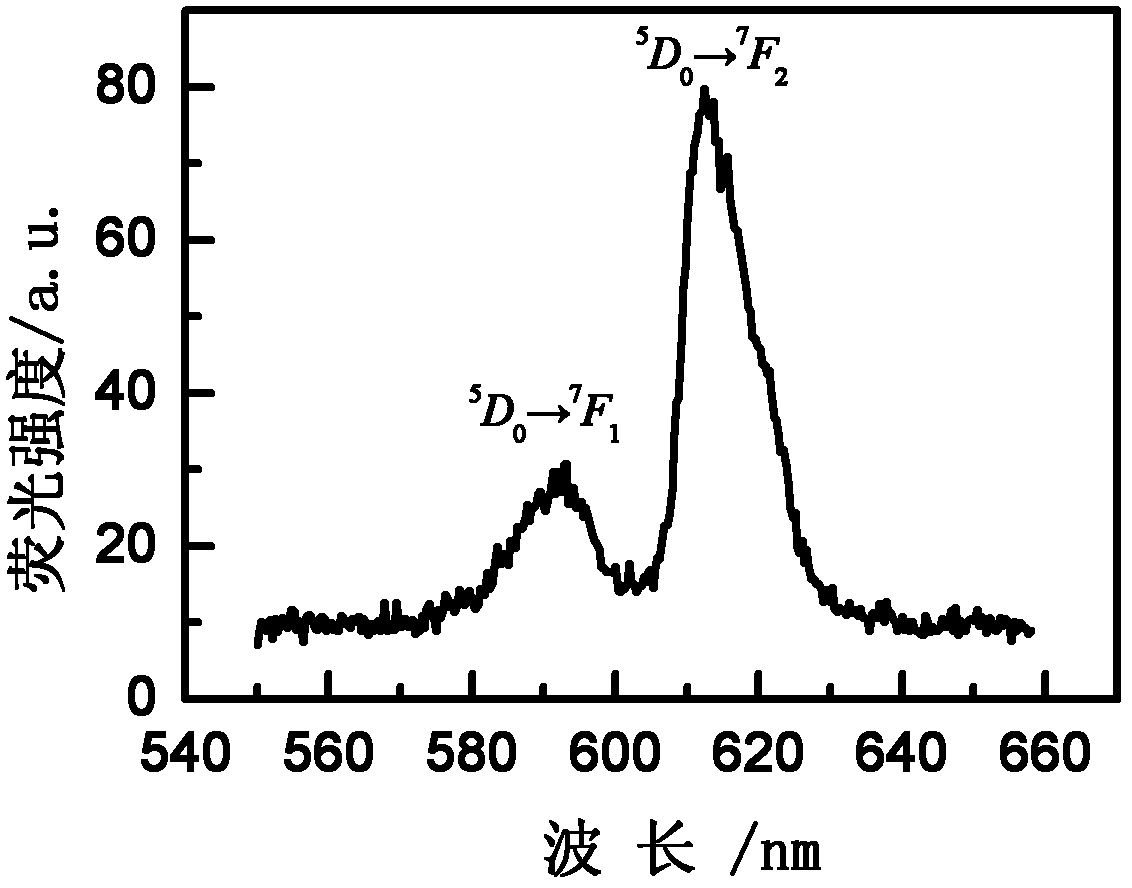

[0029] Substantially the same as Example 1, the only difference is that the raw material component is: TeO 2 : 74 mol%, PbF 2 : 14 mol%, BaF 2 : 10 mol%, Gd 2 o 3 : 1 mol%, Eu 2 o 3 : 1 mol%. Excite the scintillation glass with X-rays, measure the emitted light, and obtain image 3 The emission spectra shown are from image 3 It can be seen that there are two emission peaks at 590nm and 618nm, corresponding to Eu 3+ Ionic 5 D. 0 → 7 f 1 , 5 D. 0 → 7 f 2 transition. 5 D. 0 → 7 f 2 The intensity of the 618nm wavelength scintillation peak produced by the transition is relatively large, and there is a large scintillation light output; at the same time, Gd 3+ ions can effectively sensitize Eu 3+ The luminescence of the ions enhances the Eu 3+ The flickering glow of ions.

Embodiment 3

[0031] Substantially the same as Example 1, the only difference is that the raw material component is: TeO 2 : 85mol%, PbF 2 : 7 mol%, BaF 2 : 3 mol%, Gd 2 o 3 : 3 mol%, Tb 2 o 3 : 1 mol%, Dy 2 o 3 : 1 mol%. Excite the scintillation glass with X-rays, measure the emitted light, and obtain Figure 4 The emission spectra shown are from Figure 4 It can be seen that there are 6 emission peaks in total, and the emission peaks at 413nm and 435nm correspond to Tb 3+ of 5 D. 3 → 7 f J (J = 5, 4) energy level transitions, 487nm, 542nm, 581nm and 620nm correspond to Tb 3+ Ionic 5 D. 4 → 7 f J (J = 6, 5, 4, 3) transitions. There is no Dy in the picture 3+ ion 4 F 9 / 2 → 6 H 15 / 2 and 4 F 9 / 2 → 6 H 13 / 2 The transition corresponding to the 483 nm, 575nm emission peaks, which is due to the Dy 3+ Energy is effectively transferred to Tb through resonance transfer 3+ , so Dy 3+ Make Tb 3+ The luminous intensity is increased.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com