Self temperature limiting heat tracing strip of PTC (positive temperature coefficient) high polymer conductive composite material and preparation method thereof

A self-limiting temperature heating cable and polymer conduction technology, applied in the direction of heating element material and heating element shape, etc., can solve the problems of different thermal expansion coefficients of conductive core wires, large contact resistance of conductive core wires, and rising manufacturing costs of heating cables, etc. Achieve the effect of improving long-term use stability, good performance stability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

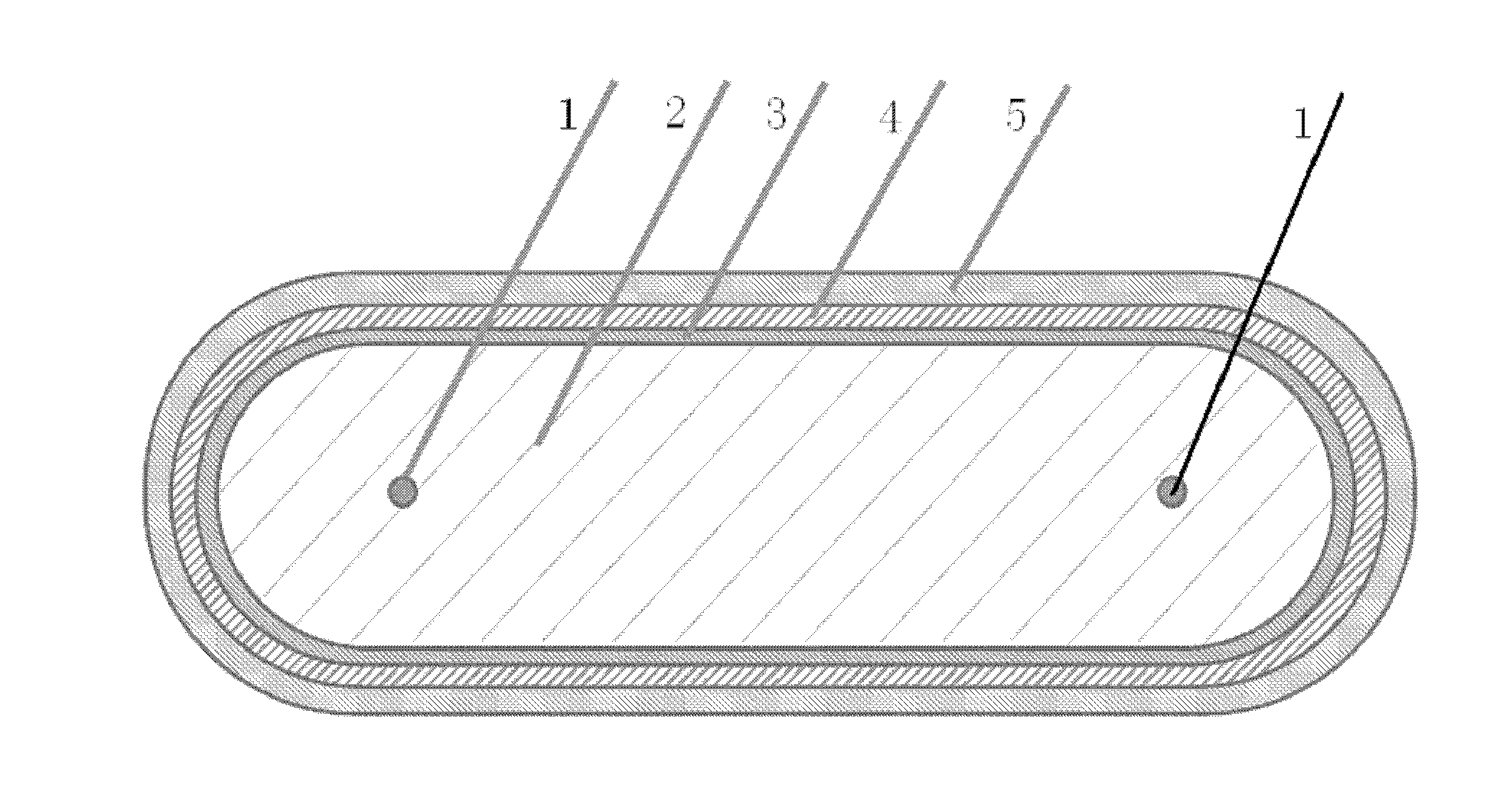

Image

Examples

preparation example Construction

[0040] The preparation method of the self-limiting temperature heating cable of the polymer conductive composite material of the present invention comprises the following steps:

[0041] Step 1. Preparation of polyethylene-based PTC conductive composite layer 2:

[0042] Step 1.1, weighing 100 parts by weight of polyethylene resin, 1 to 50 parts by weight of ethylene-methacrylate ionomer, 10 to 50 parts by weight of carbon black, 1 to 11 parts by weight of carbon fiber, and 20 to 50 parts by weight of nano calcium carbonate , 5-25 parts by weight of polyester acrylic acid oligomer, 5-25 parts by weight of stearic acid, 0.1-2.0 parts by weight of 2-methyl-1-(4-methylthiophenyl)-2-morpholine-1-acetone parts by weight, 0.001 to 0.010 parts by weight of dicumyl peroxide, 0.1 to 2.0 parts by weight of vinyl tris(2-methoxyethoxy) silane, 0.1 to 2.0 parts by weight of dodecylbenzenesulfonic acid and salicylic acid 1-10 parts by weight of amidophthalimide.

[0043] Step 1.2, mix the...

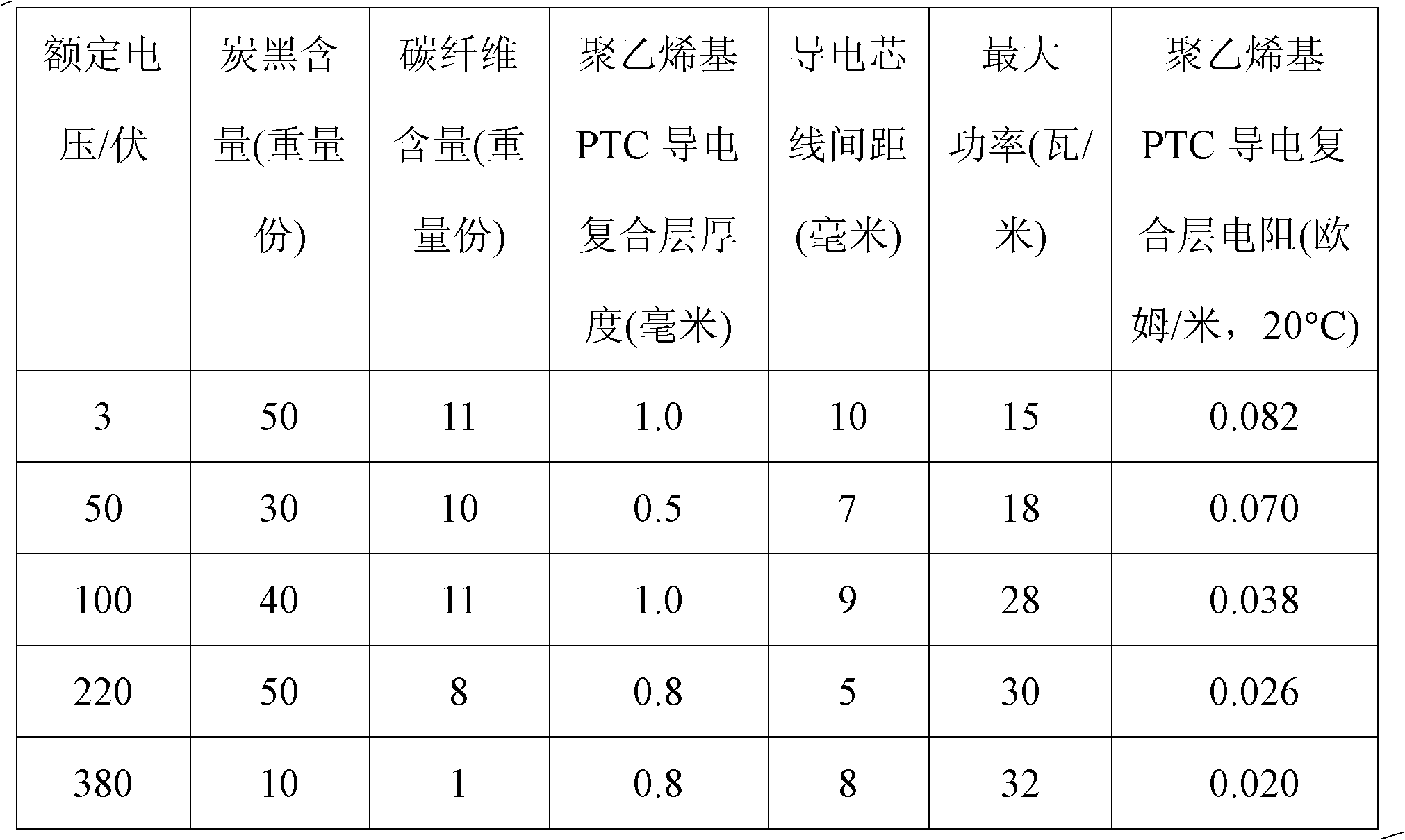

Embodiment 1

[0056] Step 1. Preparation of polyethylene-based PTC conductive composite layer 2:

[0057] Step 1.1, weigh 100kg of low-density polyethylene resin, ethylene-methacrylate ionomer 1kg, carbon black 10kg, carbon fiber 11kg, nano calcium carbonate 20kg, polyester acrylic oligomer 5kg, stearic acid 5kg, 2-methyl-1-(4-methylthiophenyl)-2-morpholine-1 -Acetone 0.1kg, dicumyl peroxide 0.001kg, vinyltris(2-methoxyethoxy)silane 0.1kg, dodecylbenzenesulfonic acid 0.1kg and salicylamidophthaloyl Imine 10kg.

[0058] Step 1.2, mix the polyethylene resin and ethylene-methacrylate ionomer weighed in step 1.1 evenly, and set aside.

[0059] Step 1.3, carbon black, carbon fiber, nano-calcium carbonate, polyester acrylic acid oligomer, stearic acid, 2-methyl-1-(4-methylthiophenyl)-2-morpholine weighed in step 1.1 - 1-acetone, dicumyl peroxide, vinyl tris (2-methoxyethoxy) silane, dodecylbenzenesulfonic acid and salicylamidophthalimide placed in a high-speed mixer Mix and stir at medium sp...

Embodiment 2

[0066] Step 1. Preparation of polyethylene-based PTC conductive composite layer 2:

[0067] Step 1.1, weigh 100kg of high-density polyethylene, 50kg of ethylene-methacrylate ionomer, 50kg of carbon black, 1kg of carbon fiber, 50kg of nano-calcium carbonate, 25kg of polyester acrylic acid oligomer, 25kg of stearic acid, and 2-methacrylic acid Base-1-(4-methylthiophenyl)-2-morpholine-1-acetone 2.0kg, dicumyl peroxide 0.01kg, vinyl tris(2-methoxyethoxy)silane 2kg, Dodecylbenzenesulfonic acid 2kg and salicylamidophthalimide 1kg.

[0068] Step 1.2, mix the polyethylene resin and ethylene-methacrylate ionomer weighed in step 1.1 evenly, and set aside.

[0069] Step 1.3, carbon black, carbon fiber, nano-calcium carbonate, polyester acrylic acid oligomer, stearic acid, 2-methyl-1-(4-methylthiophenyl)-2-morpholine weighed in step 1.1 - 1-acetone, dicumyl peroxide, vinyl tris (2-methoxyethoxy) silane, dodecylbenzenesulfonic acid and salicylamidophthalimide placed in a high-speed mixer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com