Water atomization ferrum-copper alloy powder and manufacturing method

A technology of iron-copper alloy and manufacturing method, which is applied in the field of water atomization of iron-copper alloy powder and manufacturing to improve the dimensional accuracy of powder metallurgy parts. Effect of excellent sintering dimensional change stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

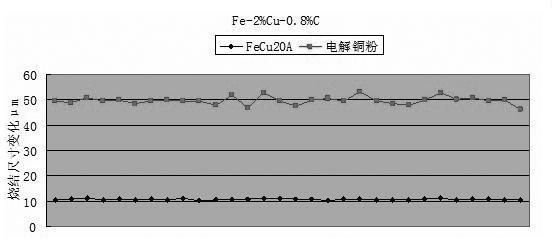

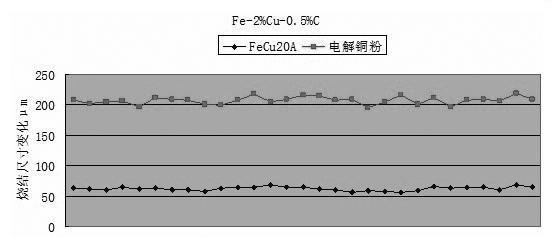

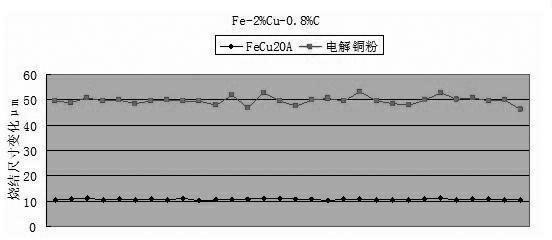

[0020] The technical solution of the present invention will be further specifically described below in conjunction with the accompanying drawings and through embodiments.

[0021] In this embodiment, an iron-copper alloy powder is atomized with water to improve the dimensional accuracy of powder metallurgy parts. The chemical composition requirements of the alloy powder are: C: 0-0.1%, Si: 0-0.3%, Mn: 0.05-0.5%, P : 0~0.05, S: 0~0.05%, Cu: 5~45%, the rest is iron; the particle size distribution requirements of alloy powder are: >150μm: 0~10%, 150-106μm: 5~25%, 106- 75μm: 10-40%, 75-45μm: 20-40%, <45μm: 10-95%.

[0022] The manufacturing method includes the following steps: smelting, water atomization, drying, reduction and crushing.

[0023] 1. Smelting: Low-carbon scrap steel is selected as raw material, and the chemical composition is based on mass percentage: C=0.3%, Mn=0.63%, Si=0.2%, S=0.05%, P=0.04%, no oil on the surface, no stains on low-carbon scrap steel ; Copper a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Ultimate tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com