Film with serrated adhesive structure and laminated support thereof

A stent-graft, serrated technology, applied in the field of medical devices, can solve problems such as tearing and low adhesion, and achieve the effects of avoiding cracking, being easy to process, and improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] refer to Figure 1-Figure 4 :

[0034] A film with a zigzag bonding structure, which cuts out the required length and width dimensions from a certain thickness of the film before making a covered stent, and is characterized in that the zigzag adhesive is cut out at the bonding site before bonding. Join the edge.

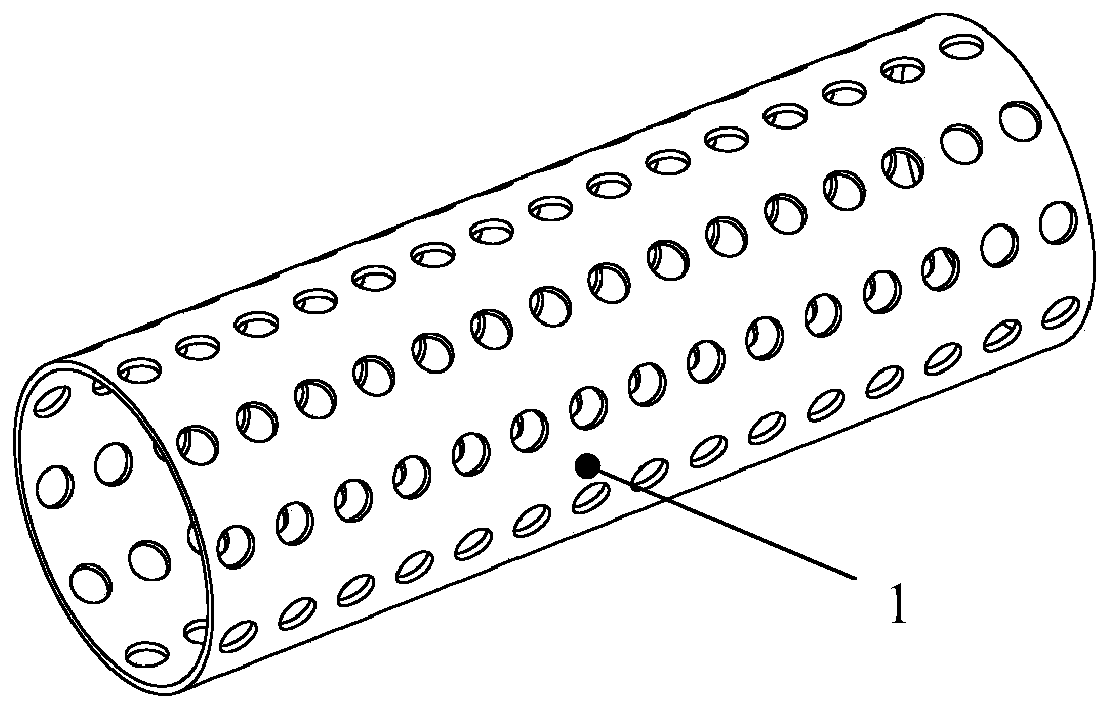

[0035] figure 1 Schematic diagram of the bare metal stent structure. The stents used in the covered stents are either bare metal stents in the prior art, or drug-eluting stents, or non-metallic stents, or degradable stents.

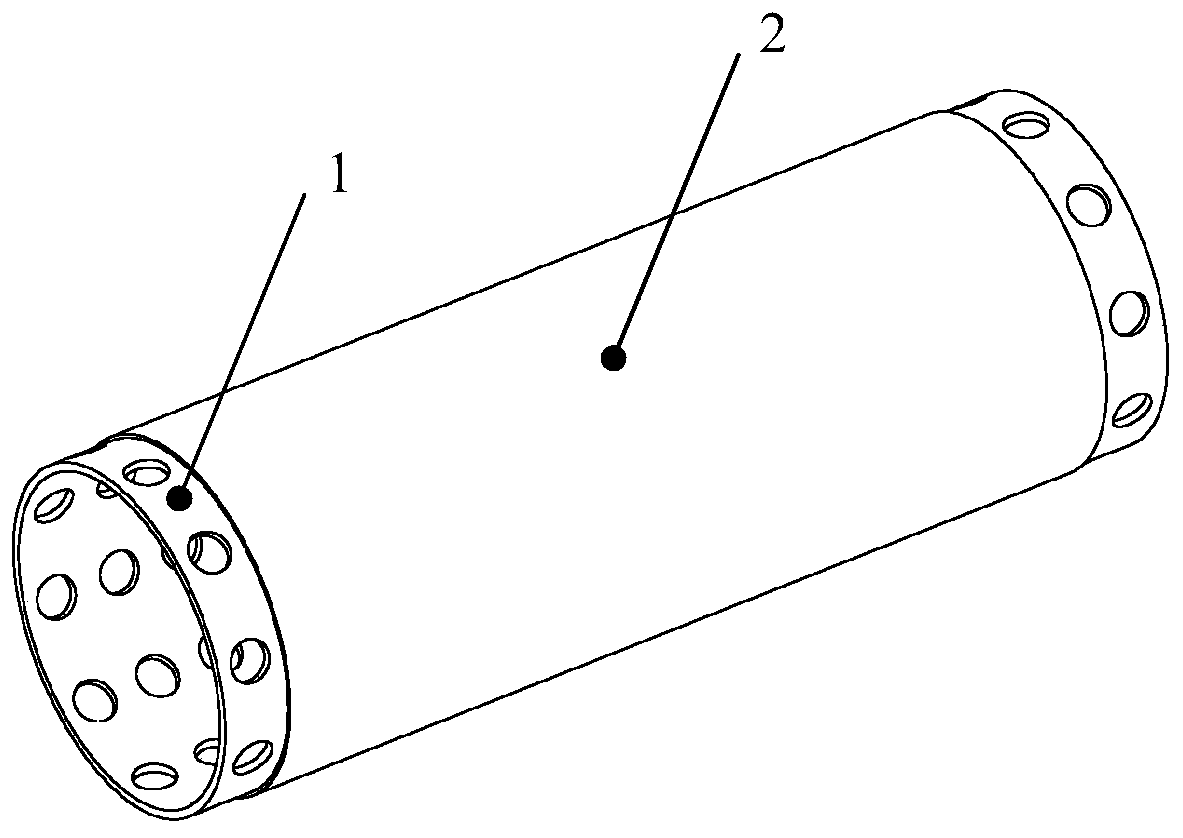

[0036] figure 2 It is a structural schematic diagram of a stent graft in the prior art.

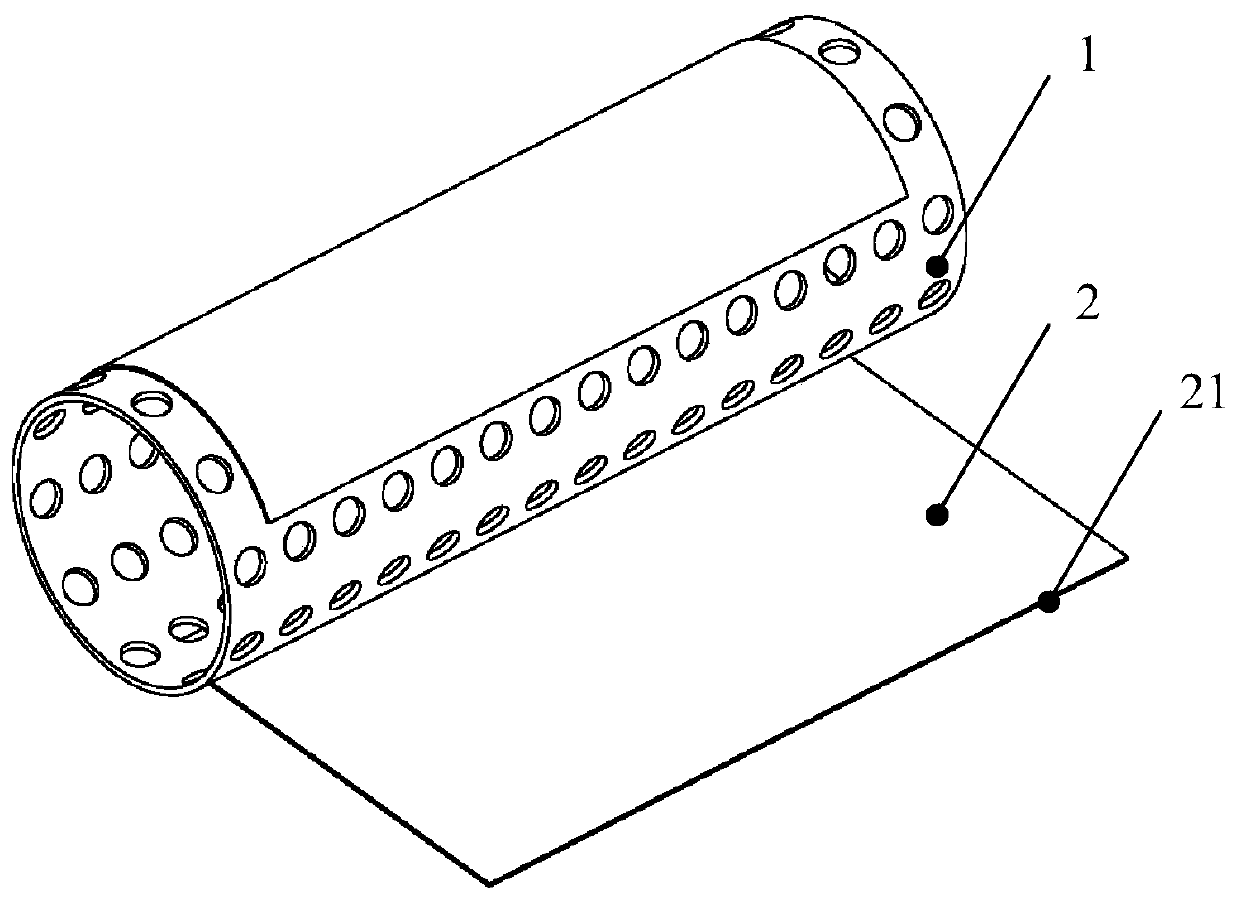

[0037] image 3 It is a structural schematic diagram (linear type) of film-covered adhesive joints in the prior art.

[0038] use Prepare covered stents from standard bare metal stents.

[0039] Calculate the film length: S=PI*D=3.14*3.5=11.0 mm.

[0040] The length is the longitudinal direction of the metal stent.

[0041] Lamination wi...

Embodiment 2

[0055] The content of this embodiment is the same as that of the first embodiment, except that the film 3 covers the inner surface of the bare metal stent 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com