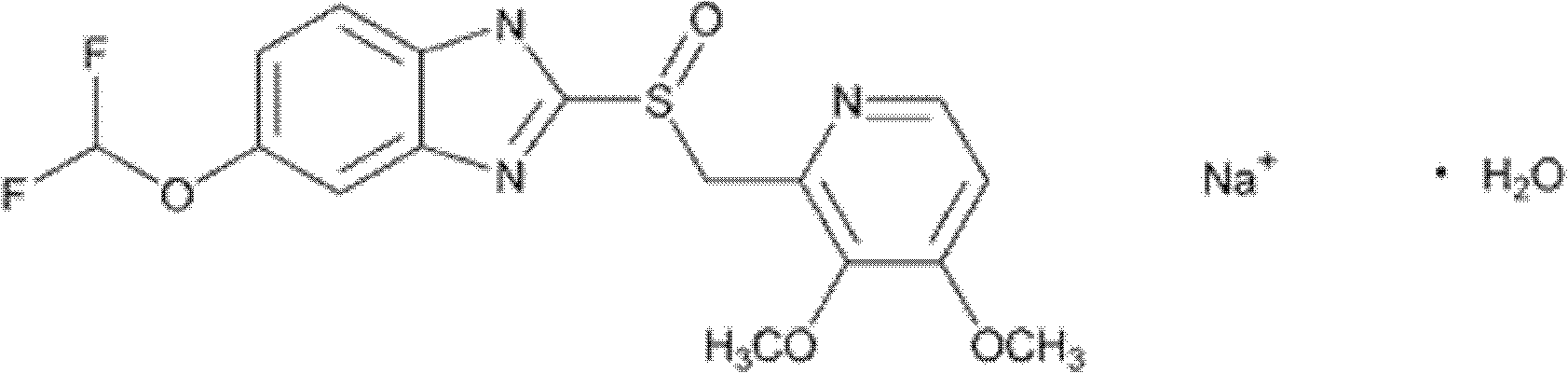

Pantoprazole sodium freeze-dried powder injection and preparation method thereof

A technology of pantoprazole sodium and freeze-dried powder injection, which is applied in the field of pharmacy, can solve problems such as blood calcium drop and calcium reduction, and achieve the effect of increasing pH value and avoiding low calcium phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

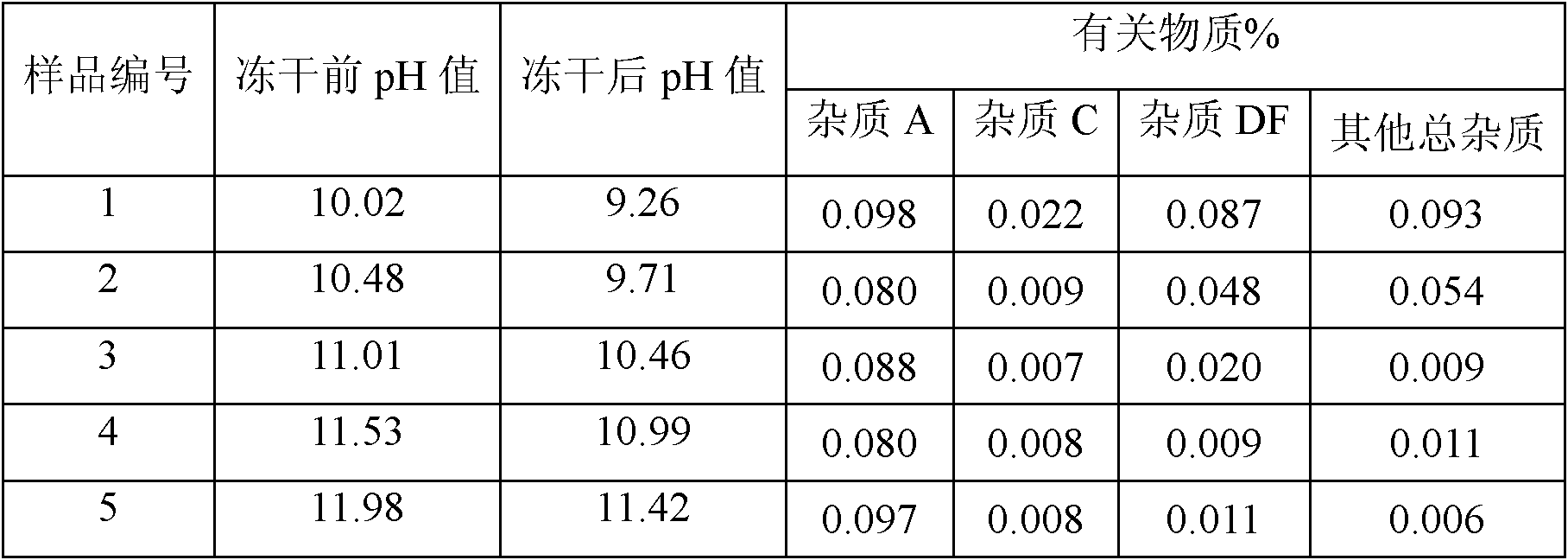

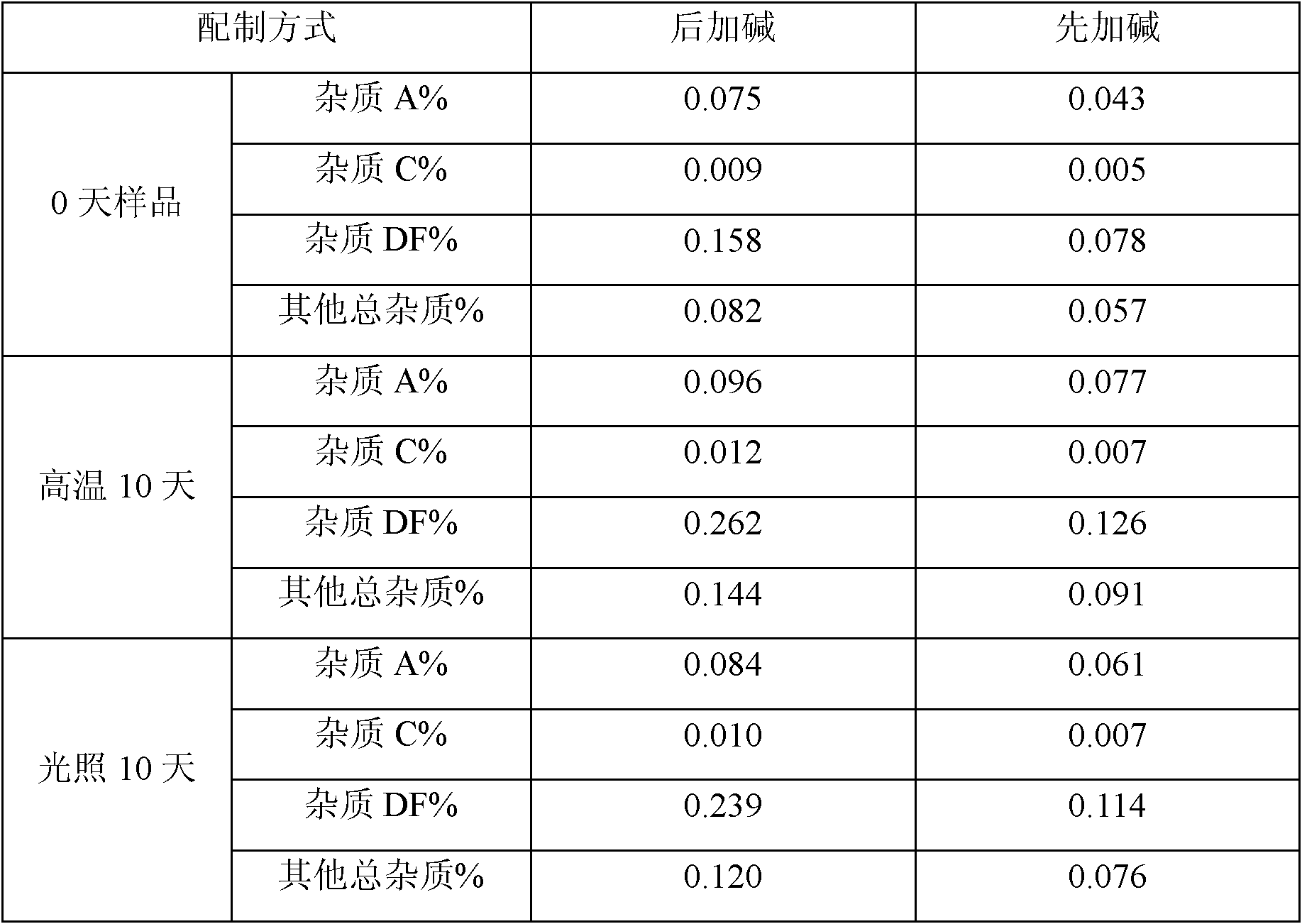

Method used

Image

Examples

Embodiment 1

[0077] Weigh 40.0g of mannitol and 2.0g of calcium sodium edetate, dissolve it with 75% full amount of water for injection, add 2.1g of sodium hydroxide, adjust the pH value of the water for injection to between 11-12, and then add pantola Sodium azole 42.3g (40.0g as pantoprazole), dissolved completely. Replenish to full volume. Add activated carbon for needles, stir for adsorption, and filter to sterilize with 0.45 μm and 0.22 μm filter membranes. Measure and calculate content, every bottle containing pantoprazole is 40mg, and the filling volume of every bottle is about 2ml l (the pH value of the solution before freeze-drying is between 11-12), is divided into 1000 bottles, half-pressed rubber stopper , freeze-drying, vacuumizing, capping, and rolling an aluminum cap to obtain the freeze-dried powder of pantoprazole sodium. After inspection, all the indicators are in compliance with the regulations, especially the content of impurities A, C, and DF are in compliance with t...

Embodiment 2

[0079] Weigh 40.0g of glucose and 2.0g of calcium sodium edetate, dissolve with 75% full amount of water for injection, add 1.9g of sodium hydroxide, adjust the pH value of the water for injection to between 11-12, and then add pantoprazole Sodium 42.3g (40.0g as pantoprazole), dissolved completely. Replenish to full volume. Add activated carbon for needles, stir for adsorption, and filter to sterilize with 0.45 μm and 0.22 μm filter membranes. Measure and calculate content, every bottle containing pantoprazole is 40mg, and the filling volume of every bottle is about 2ml (the pH value of the solution before freeze-drying is between 11-12), is divided into 1000 bottles, half-pressed rubber stopper, Freeze-drying, vacuumizing, capping, rolling an aluminum cap to obtain freeze-dried powder of pantoprazole sodium. After inspection, all the indicators are in compliance with the regulations, especially the content of impurities A, C, and DF are in compliance with the regulations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com