Fluorinated graphene oxide-lithium vanadium fluorophosphate composite material as well as preparation method and applications thereof

A technology of lithium vanadium fluorophosphate and composite material, applied in the field of fluorinated graphene oxide-lithium vanadium fluorophosphate composite material and preparation thereof, can solve the problems of poor battery high current performance, poor stability of graphite oxide, easy moisture absorption and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

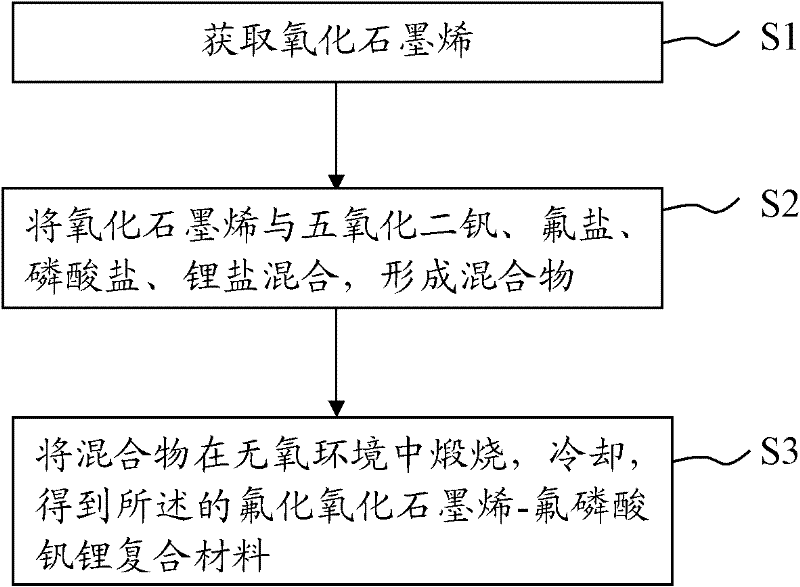

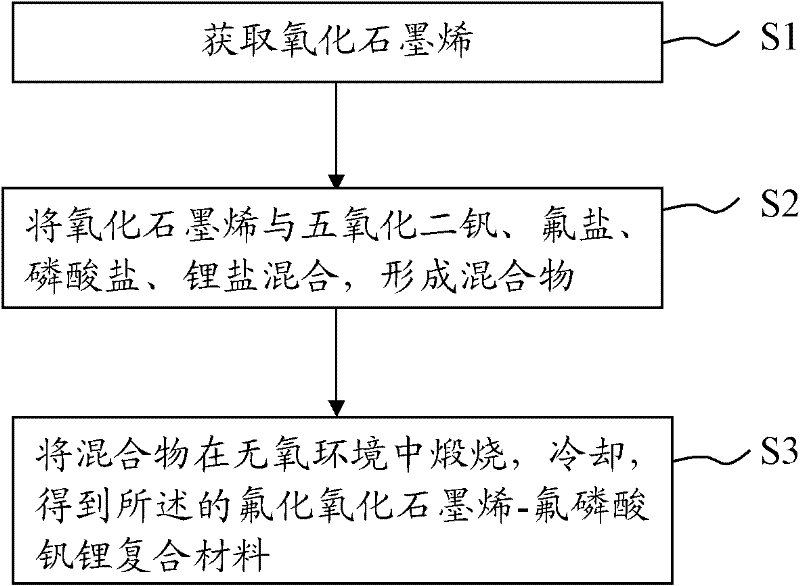

[0017] The example of the present invention provides a method for preparing a fluorinated graphene oxide-lithium vanadium phosphate composite material with simple process, low cost and suitable for industrial production. For the process flow of the preparation method of the fluorinated graphene oxide-lithium vanadium phosphate composite material, please refer to figure 1 , the method includes the following steps:

[0018] S1: Obtain graphene oxide;

[0019] S2: mixing the graphene oxide with vanadium pentoxide, fluoride salt, phosphate salt, and lithium salt to form a mixture;

[0020] S3: Calcining and cooling the mixture in an oxygen-free environment to obtain the fluorinated graphene oxide-lithium vanadium phosphate composite material.

[0021] Specifically, in step S1 of the method for preparing the fluorinated graphene oxide-lithium vanadium phosphate composite material, please refer to Example 1 for the method for obtaining graphene oxide.

[0022] In the S2 step of t...

Embodiment 1

[0032] The preparation of fluorinated graphene oxide-lithium vanadium phosphate composite material, its method and technological process are as follows:

[0033] S11: Graphite oxide: Graphene oxide is prepared by the improved Hummers method; the specific steps are: add 20g of graphite powder (50 mesh), 10g of potassium persulfate and 10g of phosphorus pentoxide to concentrated sulfuric acid at 80°C, and stir evenly , cooled for more than 6 hours, then filtered, washed until neutral, dried, and added the dried sample to 0°C, 230ml of concentrated sulfuric acid, then added 60g of potassium permanganate, and kept the temperature below 20°C, then in After keeping in an oil bath at 35°C for 2 hours, slowly add 920ml of deionized water, and after 15 minutes, continue to add 2.8L of deionized water (which contains 50ml of 30% hydrogen peroxide), after which the color of the mixture turns bright yellow, and pump it while it is hot Filter, and finally wash with 5L of 10% hydrochloric a...

Embodiment 2

[0042] The preparation of fluorinated graphene oxide-lithium vanadium phosphate composite material, its method and technological process are as follows:

[0043] S21: graphite oxide: refer to the S11 step in embodiment 1;

[0044] S22: Preparation of fluorinated graphene oxide modified lithium vanadium phosphate cathode material: take 0.098mol of V 2 o 5 Powder, 0.195 mol of LiAC, 0.205 mol of NH 4 h 2 PO 4 , 20g graphene oxide, 0.049mol glucose and 18.5gNH 4 After F is mixed evenly, it is calcined at 500°C for 10 h under the protection of argon inert gas, and after natural cooling, the composite cathode material of fluorinated graphene oxide and lithium vanadium phosphate is obtained.

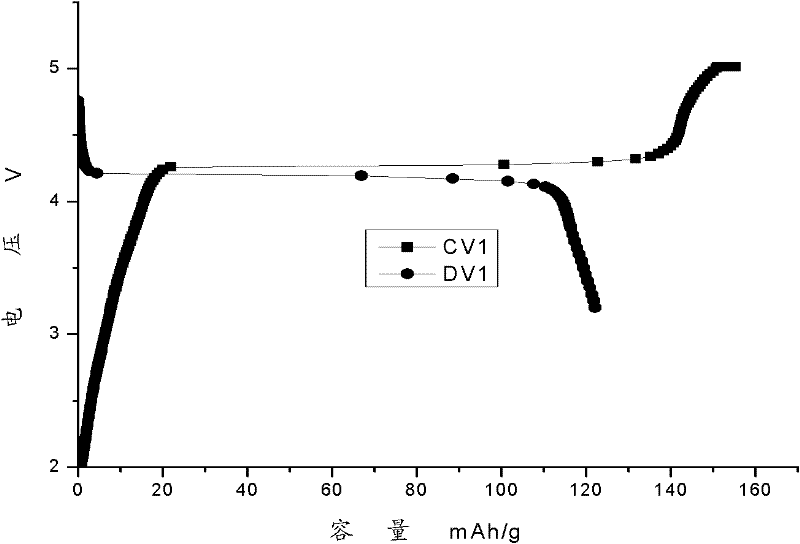

[0045] The fluorinated graphene oxide-lithium vanadium phosphate composite material prepared in this example was used in the preparation of positive electrodes. The preparation method of the positive electrode sheet includes the preparation of the electrode sheet, rolling, and sheet cutt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com