Silicon-based negative electrode material of lithium ion battery, preparation method of silicon-based negative electrode material, and battery

A silicon-based negative electrode material and lithium-ion battery technology, applied in battery electrodes, lithium batteries, nanotechnology for materials and surface science, etc., can solve problems such as carbon film cracking, material electrochemical contact failure, and cycle attenuation. Achieve the effects of stable structure performance, high rate performance and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

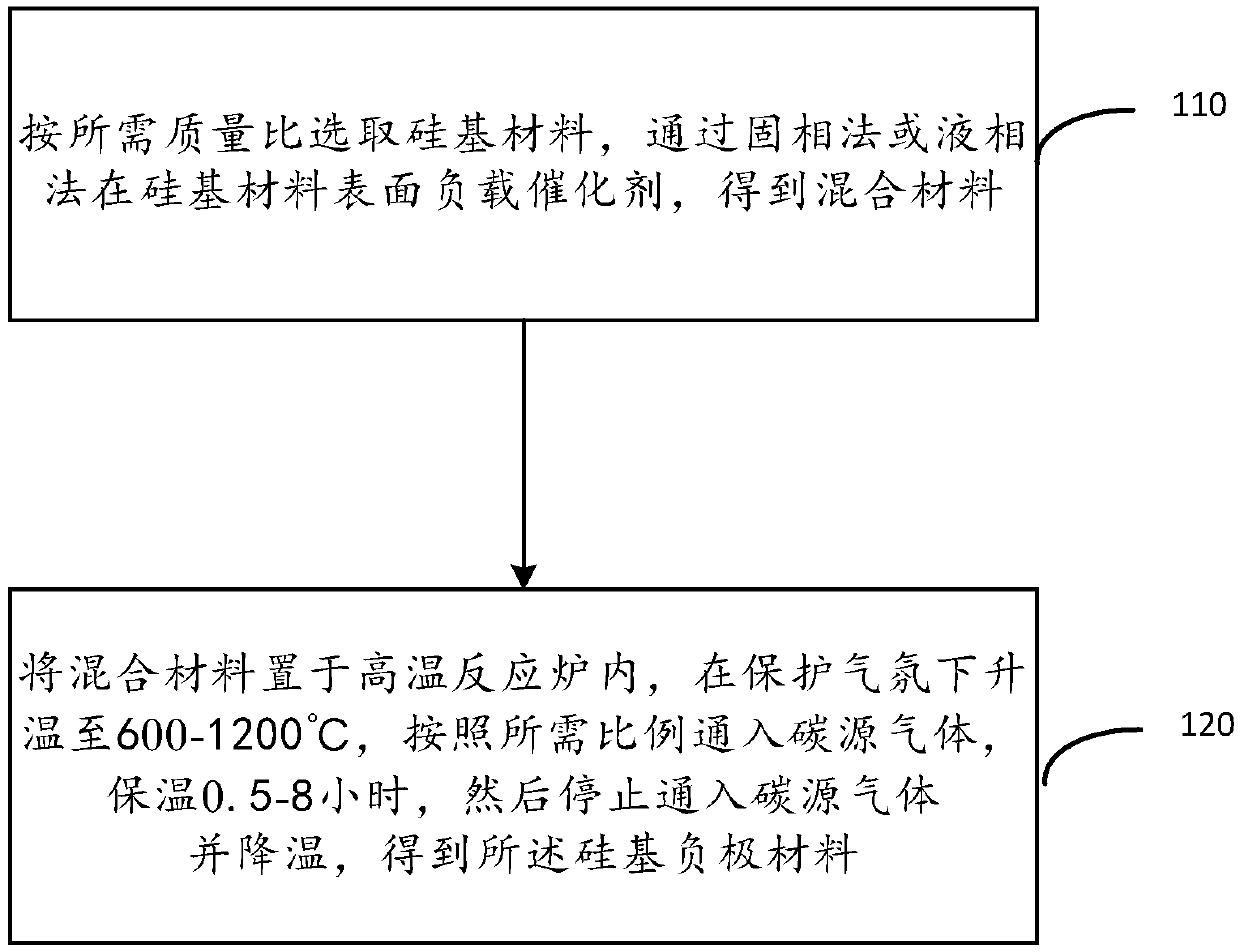

[0048] The embodiment of the present invention provides the preparation method of above-mentioned silicon-based negative electrode material of lithium ion battery, such as figure 1 The flow chart shown, its steps include:

[0049] Step 110, selecting a silicon-based material according to the required mass ratio, and loading a catalyst on the surface of the silicon-based material by a solid-phase method or a liquid-phase method to obtain a mixed material;

[0050] Among them, the silicon-based material is a powder material containing electrochemically active silicon, including one or more mixtures of nano-silicon-carbon composite materials, silicon oxide materials, modified silicon oxide materials, and amorphous silicon alloys; Chemically active silicon accounts for 0.1wt%-90wt% of the silicon-based material;

[0051] Catalysts include iron, cobalt, nickel, copper, zinc, aluminum, magnesium, lithium, gold, silver, ruthenium, platinum and other metal elements, inorganic compoun...

Embodiment 1

[0062] This embodiment provides a specific method for preparing a silicon-based negative electrode material for a lithium-ion battery:

[0063] First, after fully mixing the commercial silicon oxide powder and the aqueous solution of ferric chloride, spray drying to obtain the silicon oxide powder loaded with the catalyst; wherein the weight fraction of the ferric chloride is 5 / 10,000;

[0064] Second, the silicon oxide powder of the above-mentioned loaded catalyst is placed in a high-temperature rotary furnace, and the Ar:H 2 =1:0.1 under the mixed gas, the temperature was raised to 900°C, acetylene gas equal to hydrogen gas was introduced, and the temperature was kept for 4 hours, then the acetylene gas was stopped, and the temperature was lowered to obtain a silicon oxide composite material with carbon nanotubes grown in situ.

[0065] The SEM experiment of the present invention is carried out on S-4800, and the following examples are all the same.

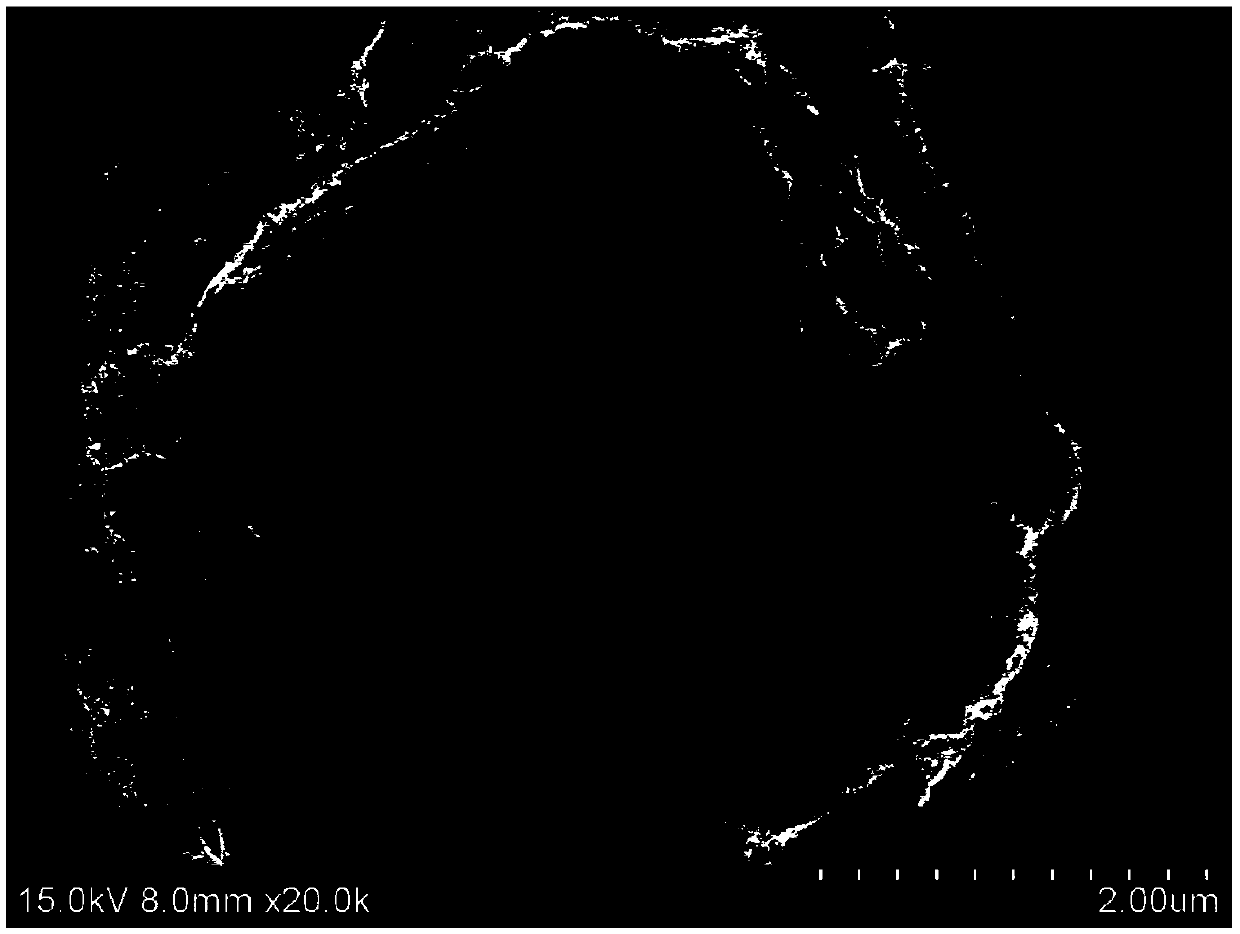

[0066] The SEM image o...

Embodiment 2

[0073] This embodiment provides a specific method for preparing a silicon-based negative electrode material, including:

[0074] First, after fully mixing the commercial silicon oxide powder and nano-iron oxide in a high-speed VC machine, the catalyst-loaded silicon oxide powder is obtained; the weight fraction of nano-iron oxide is 5 / 10,000;

[0075] Second, the silicon oxide powder of the above-mentioned loaded catalyst is placed in a high-temperature rotary furnace, and the Ar:H 2 =1:0.1 under the mixed gas, the temperature was raised to 900°C, acetylene gas equal to hydrogen gas was introduced, and the temperature was kept for 4 hours, then the acetylene gas was stopped, and the temperature was lowered to obtain a silicon oxide composite material with carbon nanotubes grown in situ.

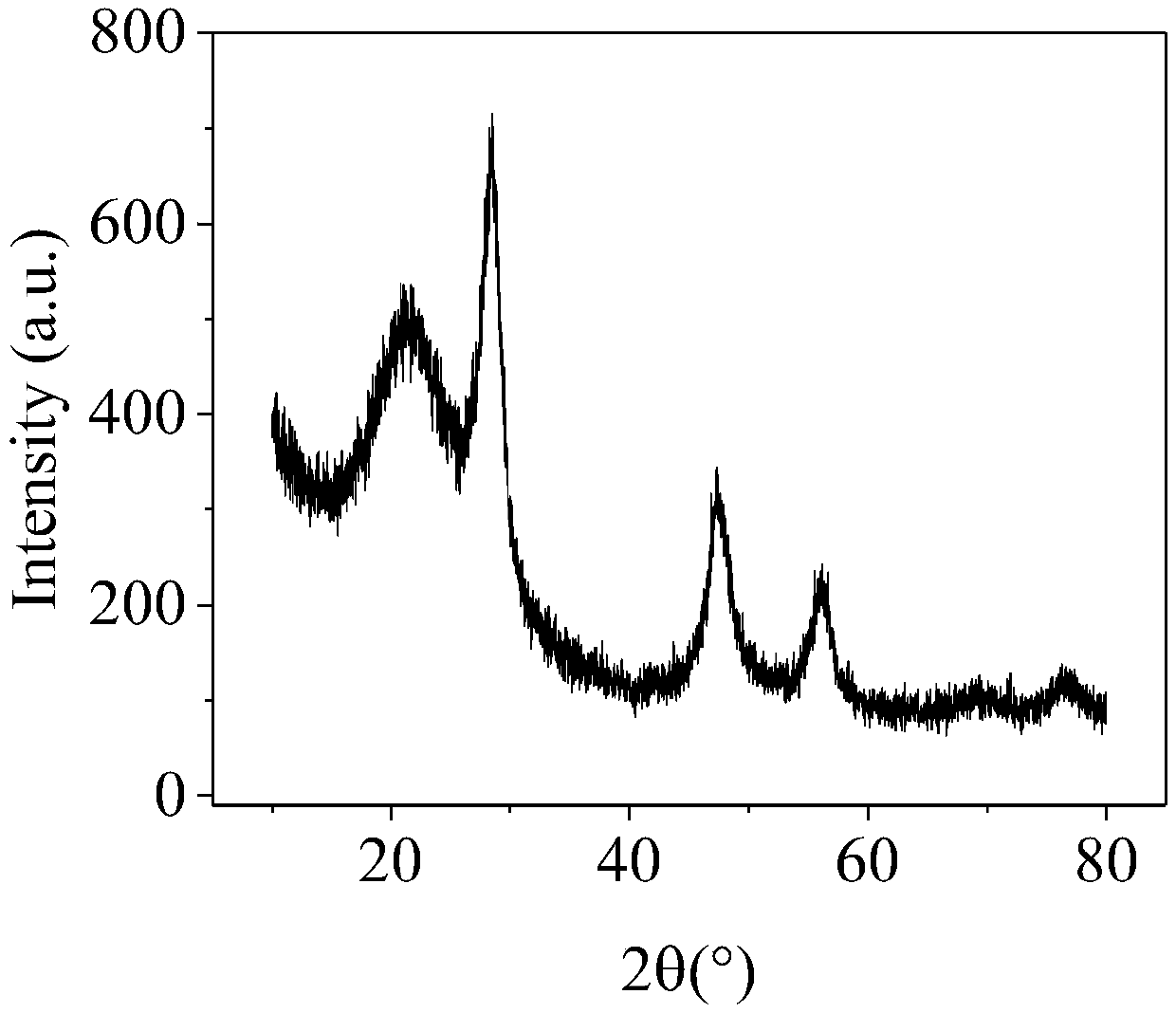

[0076] The Raman spectrum of the material obtained in this embodiment is shown in Figure 7 . Depend on Figure 7 It can be seen that at 475cm -1 There are bulges of amorphous silicon;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com